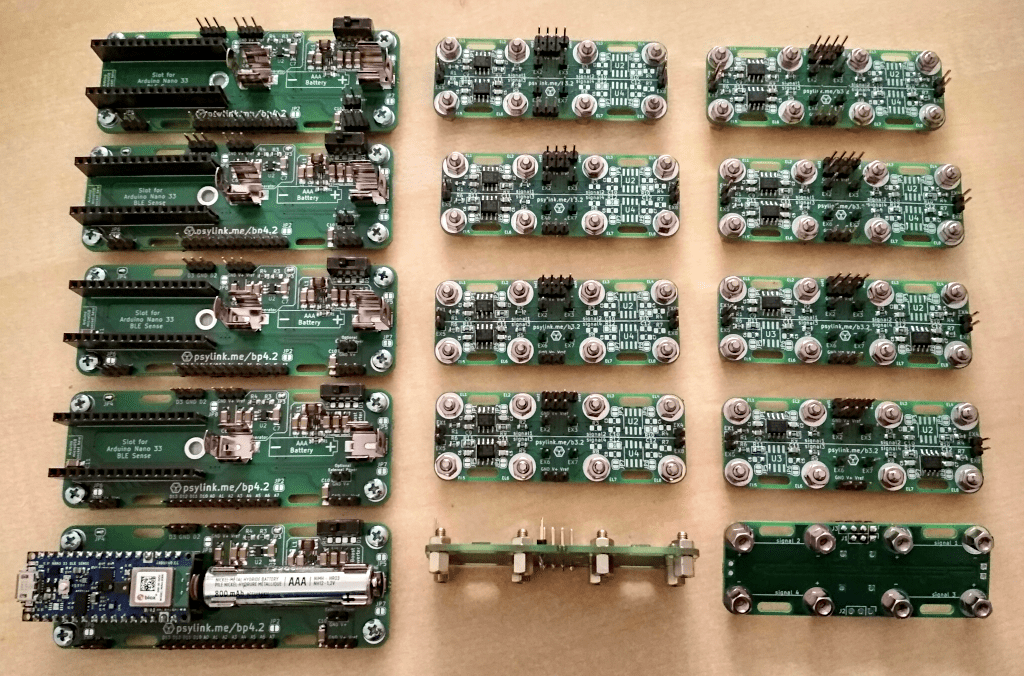

Mass production

More and more people are asking me to send them a PsyLink prototype! I've written some Tutorials to help the users to get started, and I'm working diligently to assemble them all. Can't wait to see the ways in which they will be used. :)

Request your own pre-assembled PsyLink now too!

Unlike software, unfortunately, you can't just download a PsyLink and use it right away. It takes me about 1-1.5 hours per module to assemble these. I wish I could automate and outsource more of the assembly process, but I don't see a low hanging fruit worth exploring so far. Still, I'm happy about the progress, since I'm now ~5x faster than when I sent out the first Prototype 7.

Currently, the assembly process consists of:

- File off the rough break-off points on the PCB to avoid scratching the skin

- Solder on the SMD components

- Do optical quality tests, as well as tests with a multimeter on critical parts

- Since my pin sockets have 16 pins and the Arduino has 15 pins, I cut off one of the pins of the socket

- Cut the downward-facing pins of all through-hole components down to ~1.4mm so that they don't stick out of the PCB and possibly scratch the skin

- Solder on the Through-hole components (except battery clips)

- Plug in the battery clips, bend its pins inward so that they don't scratch the skin, (the end may break off but that's ok), and solder them on

- Clean off solder flux stains with Isopropyl Alcohol on the sides that face the skin

- Cover the bottom of the power module with insulating tape to avoid skin contact

- Screw on the electrodes / legs

- Wire up everything as described in the wiki

- Push the elastic band through the respective holes to connect the boards together

- Do a test run of the entire system

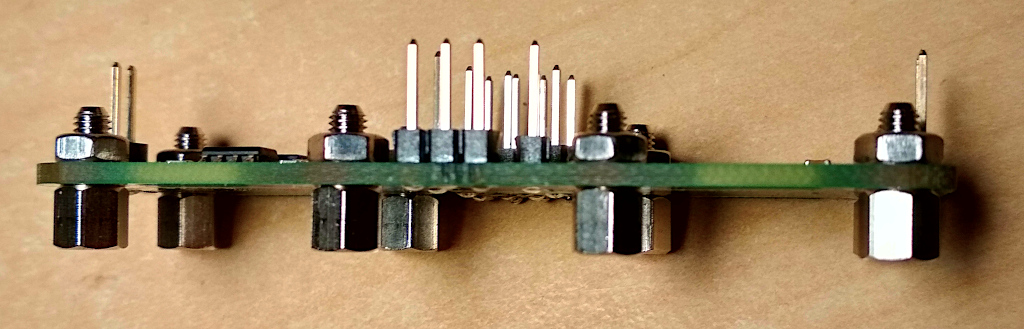

Outsourcing pick&place and soldering of the components would be helpful, but the through-hole components (pin headers/sockets, switch, battery clip) need special treatment: I have to trim the pins so that they don't stick out of the PCB and scratch the skin. I doubt that any pick&place contractor will do this for me. This close-up shot of a Electrode Module 3.2 shows it well, that there are no sharp points under the pin headers, just round solder blobs:

But I could at least outsource the soldering of SMD components. Let's see if I can find something cheap.

If you have tips to accelerate the assembly process, please reach out to us.

- Newer post: Next Steps & Resources

- Older post: Prototype 9 + Matrix Chatroom

- All posts on a single page

- Date: 2022-02-15

- Author: Roman