Development Log

PsyLink is experimental hardware for reading muscle signals and using them to e.g. control the computer, recognize gestures, play video games, or simulate a keyboard. PsyLink is open source, sEMG-based, neural-network-powered, and can be obtained here.

This blog details the steps of building it and shows recent developments. Subscribe to new posts with any RSS reader, and join the community on the Matrix chatroom.

Intro

We don't have to drill a hole into skull to get access to your nerve signals.

Muscles naturally amplify them, allowing us to easily read them through skin,

and use them for useful things like controlling a computer or an artificial

limb.

This is not science fiction, check out what's out there already:

You could argue that we use our nerves/muscles to control keyboards already

(and pretty much anything else). And for the time being, there are clearly

superior human input devices. But there are reasons to do this:

- Bandwidth: Keyboards are limited to ~120wpm (~84 bit/s). Hopefully we can squeeze out some more by sapping the nerves directly.

- Hands: Not everybody has them. You also may not want to use them, e.g. due to injury, or because they're occupied with other tasks.

- Cyberpunk: The books predicted there will be neural interfaces in the future, therefore we must create them.

This page documents my process of building one. Note that I'm no expert and I

neither have a plan, nor do I know what I'm doing. I just thought, how hard

can it be? If the architect of the Internet Exploder can build

one,

surely I can do it to.

The Idea

└2021-04-03, by Roman

On this day, I got the idea and started researching EMG design and signal

processing, motor neurology basics, as well as existing projects.

Soon I realized that I will need a microcontroller to record and process the

signals. I considered the Raspberry Pi Pico and Arduino Nano 33 BLE Sense, and chose the Arduino because:

- Bluetooth

- More analog-to-digital converter inputs

- TensorFlow Lite support, which would allow me to leverage neural networks for signal processing. This is a bit of a stretch, can't wait to get disappointed by this :)

I wish there was a decent battery/UPS shield, couldn't find one so far.

Baby Steps

└2021-04-08, by Roman

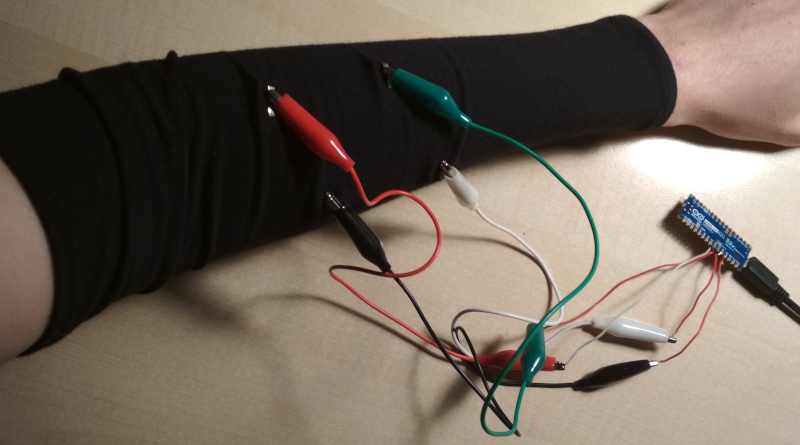

The Arduino arrived. I have no electrodes though. But what are electrodes,

just some pieces of metal taped to your skin, right? Let's improvise that:

There are two pieces of aluminum foil taped to my skin, held together with blue

medical wrap.

The educational material about electromyographs that I've seen described a

chain of hardware elements to process and clean up the signal:

- amplification

- filtering

- rectification

- antialiasing

- smoothing

- averaging

- etc.

But I thought, let's focus on the MVP. Why not simply hook the electrodes

straight to the analog input pins of the Arduino with some alligator clamps?

Worked fine. I did minimal signal processing in software though, you

can find the source code here.

This video shows the myoelectric signal on Arduino IDE's built-in signal

plotter:

F-Zero

└2021-04-09, by Roman

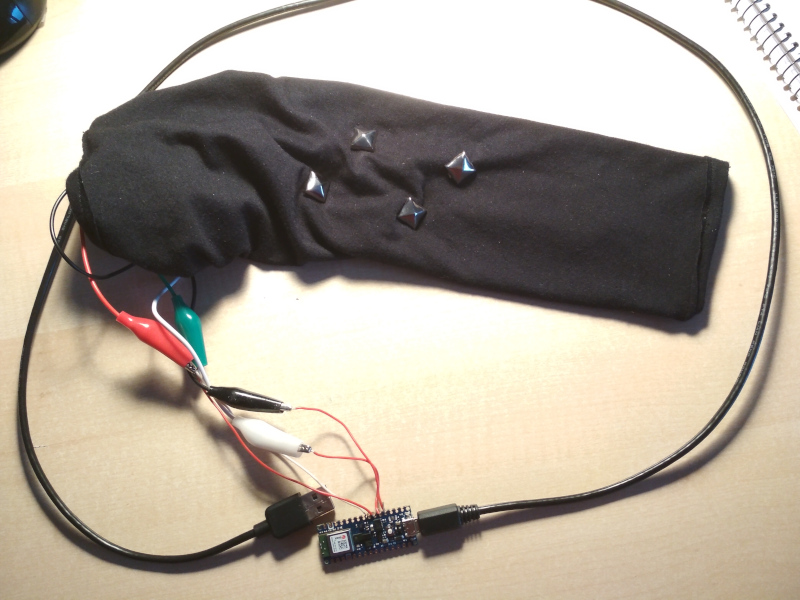

The look of the first device was way too unprofessional, so I pulled out my

sewing machine and made a custom tailored sleeve from comfortable modal fabric.

On the inside, I attached some recycled studs that served as electrodes. Who

needs that expensive stuff they sell as electrodes when a piece of iron

suffices?

This time it had 4 electrodes. I targeted the middle and the distal end of two

muscles, the Brachioradialis

and the Extensor carpi radialis

longus.

I picked those muscles at random, because I honestly don't know what the fuck I

am doing.

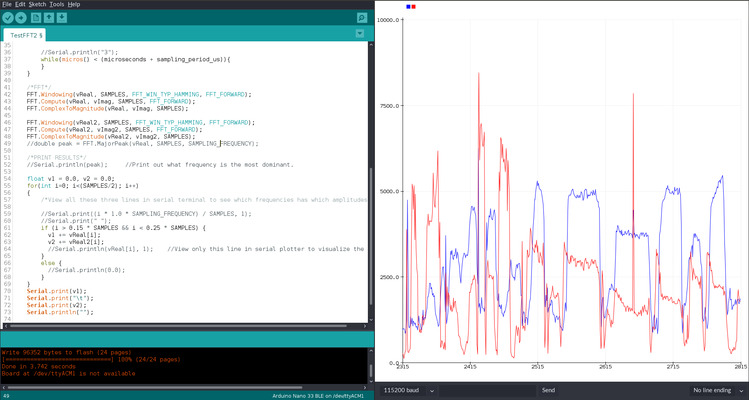

Software-wise, I played around with moving average

and got reasonable signals, but it was clear that there was too much noise.

How to filter, though? I'm not going to solder some bandpass filter, that's

too slow and inflexible. There are simple algorithms for doing it in software

(link 1,

link 2),

but something seemed off about this method. In the end, I decided to learn how

to do a Fourier transform on the Arduino.

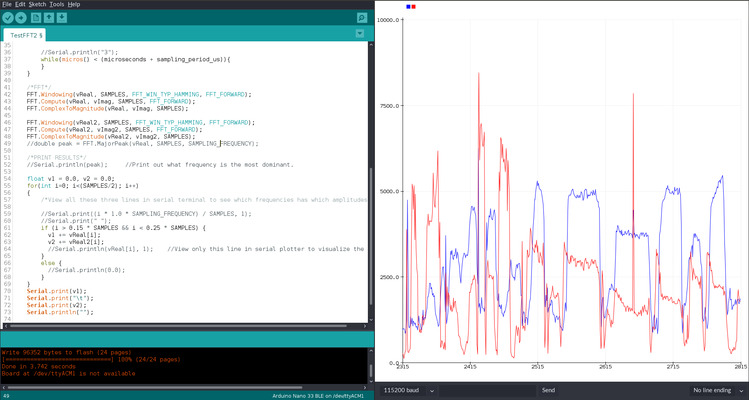

With this code

(inspired by this post),

I took 64 samples at a sampling rate of 1kHz, performed the Fourier transform,

cut out anything under 30% and over 50% of my frequency range, and then summed

up the amplitudes of the remaining frequencies to generate the output.

Still very crude, but it allowed me to get distinctive signal patterns for

various positions of my arm:

I was genuinely surprised that I got information of this fidelity and

usefulness from just hooking up 4 ADC's to semi random places of my forearm and

a software bandpass filter. This was good enough to use it as a basic input

device!

I wondered, can I control a racing car game with this?

To test that, I built this program

to read out the signals and convert certain ranges of values to keyboard

presses of the keys Left and Right. The value ranges need to be

calibrated before each use: I held my left arm like I'm grabbing an invisible

steering wheel, moved it left and right, and looked hard at the signal values

to find correlations like "signal A is always below X if and only if I steer

left". Once the calibration is done, the invisible steering wheel turned into

a magical keyboard with 2 keys =D

Right away I tried it out to steer in my favorite racing game, F-Zero:

Note that in addition to the steering wheel, I used my other hand to

accelerate.

I loved it, but there is still a lot of work to be done. The calibration is a

pain, especially since it needs to be repeated if the electrodes move too much,

which happens a lot with this kind of sleeve. Also I want more electrodes,

better signal processing, and data transfer via Bluetooth so I can run it off a

battery.

Adding some AI

└2021-04-11, by Roman

Most neural interfaces I've seen so far require the human to train how to use

the machine. Learn unintuitive rules like "Contract muscle X to perform action

Y", and so on. But why can't we just stick a bunch of artificial neurons on top

the human's biological neural network, and make the computer train them for us?

While we're at it, why not replace the entire signal processing code by a bunch

of more artificial neurons? Surely a NN can figure out to do a bandpass filter

and moving averages, and hopefully come up with something more advanced than

that. The more I pretend that I know anything about signal processing, the

worse this thing is going to get, so let's just leave it to the AI overlords.

The Arduino Part

The Arduino Nano 33 BLE Sense

supports TensorFlow Lite,

so I was eager to move the neural network prediction code onto the

microcontroller, but that would slow down the development, so for now I just

did it all on my laptop.

The

Arduino code

now just passes through the value of the analog pins to the serial port.

Calibrating with a neural network

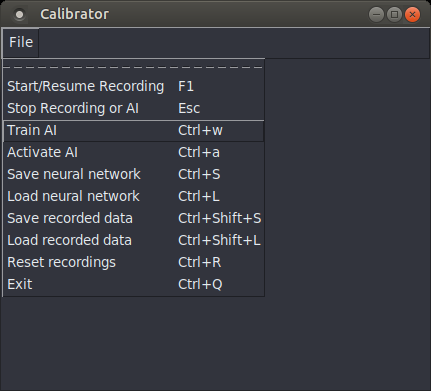

For this, I built a simple user interface, mostly an empty window with a menu

to select actions, and a key grabber.

(source code)

The idea is to correlate hand/arm movements with keys that should be pressed

when you perform those hand/arm movements. To train the AI to understand you,

perform the following calibration steps:

- Put on the device and jack it into your laptop

- Start the Calibrator

- Select the action "Start/Resume Recording" to start gathering training data

for the neural network

- Now for as long as you're comfortable (30 seconds worked for me), move your

hand around a bit. Hold it in various neutral positions, as well as

positions which should produce a certain action. Press the key on your

laptop whenever you intend your hand movement to produce that key press.

(e.g. wave to the left, and hold the left arrow key on the laptop at the

same time) The better you do this, the better the neural network will

understand wtf you want from it.

- Holding two keys at the same time is theoretically supported,

but I used TKinter

which has an unreliable key grabbing mechanism. Better stick to single

keys for now.

- Tip: The electric signals change when you hold a position for a couple

seconds. If you want the neural network to take this into account, hold

the positions for a while during recording.

- Press Esc to stop recording

- Save the recordings, if desired

- Select the action "Train AI", and watch the console output. It will train

it for 100 epochs by default. If you're not happy with the result yet, you

can repeat this step until you are.

- Save the AI model, if desired

- Select the action "Activate AI". If everything worked out, the AI overlord

will now try to recognize the input patterns with which you associated

certain key presses, and press the keys for you. =D

Results

I used this to walk left and right in 2020game.io and it

worked pretty well. With zero manual signal processing and zero manual

calibration! The mathemagical incantations just do it for me. This is awesome!

Some quick facts:

- 8 electrodes at semi-random points on my forearm

- Recorded signals for 40s, resulting in 10000 samples

- I specified 3 classifier labels: "left", "right", and "no key"

- Trained for 100 epochs, took 1-2 minutes.

- The resulting loss was 0.0758, and the accuracy was 0.9575.

- Neural network has 2 conv layers, 3 dense, and 1 output layer.

Video demo:

Still a lot of work to do, but I'm happy with the software for now. Will tweak

the hardware next.

Now I'm wondering whether I'm just picking low hanging fruits here, or if

non-invasive neural interfaces are really just that easy. How could CTRL-Labs

sell their wristband to Facebook for $500,000,000-$1,000,000,000?

Was it one of those scams where decision-makers were hypnotized by buzzwords

and screamed "Shut up and take my money"? Or do they really have some secret

sauce that sets them apart? Well, I'll keep tinkering. Just imagine what this

is going to look like a few posts down the line!

Cyber Gauntlet +1

└2021-04-13, by Roman

So if you ever worked with electromyography, this will come to no surprise to

you, but OMG, my signal got so much better once I added a ground electrode and

connected it to the ground pin of the Arduino. I tried using a ground

electrode before, but connected it to AREF instead of GND, which had no effect,

so I prioritized other branches of pareto improvement.

I am once again confused and surprised that I got ANY useful results before.

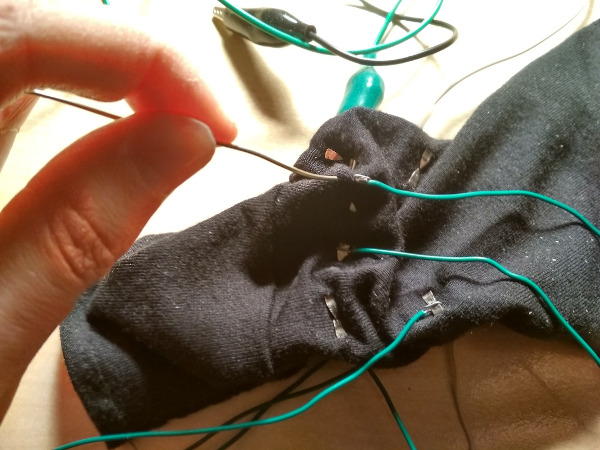

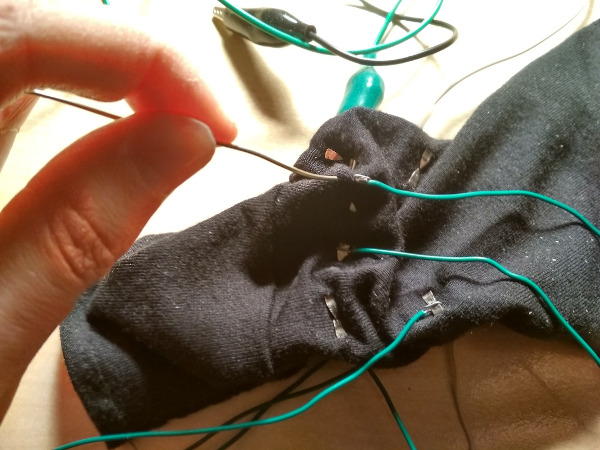

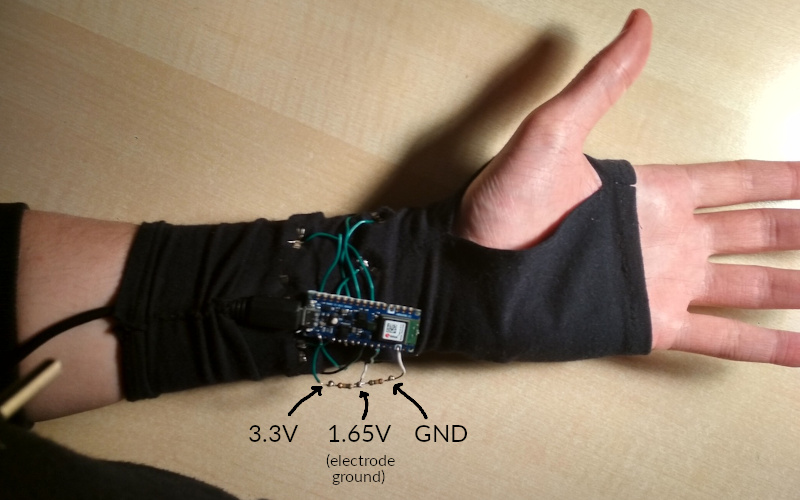

For prototype #3, I moved the electodes further down towards the wrist in hope

that I'll be able to track individual finger movements. It had 17 electrodes,

2x8 going around the wrist, as well as a ground electrode at the lower palm.

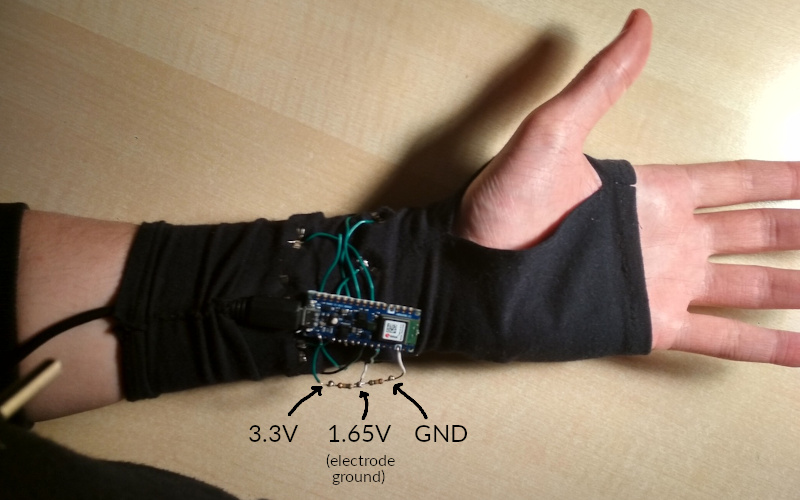

Only 9 of the 17 electrodes are connected, 8 directly to the ADC pins, and one

to 1.65V, which I created through a

voltage divider using

two 560kΩ resistors between the 3.3V and GND pins of the Arduino, so that the

electrode signals will nicely oscillate around the middle of the input voltage

range.

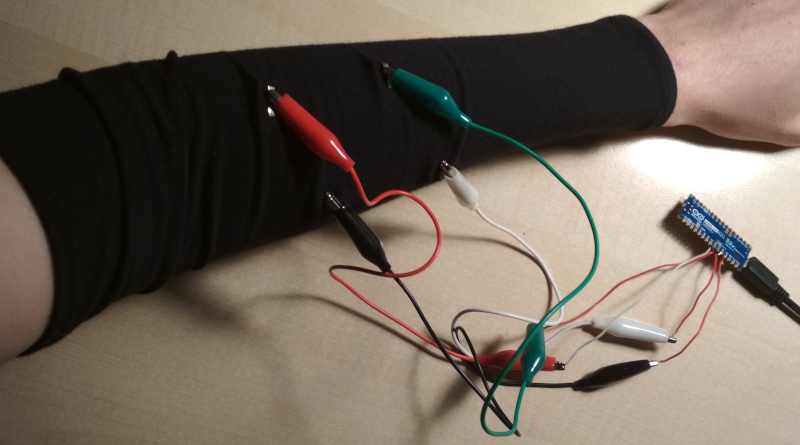

It all started out like a piece of goth armwear:

Photo from the testing period:

Soldering wires to the electrodes:

The "opened" state shows the components of the device:

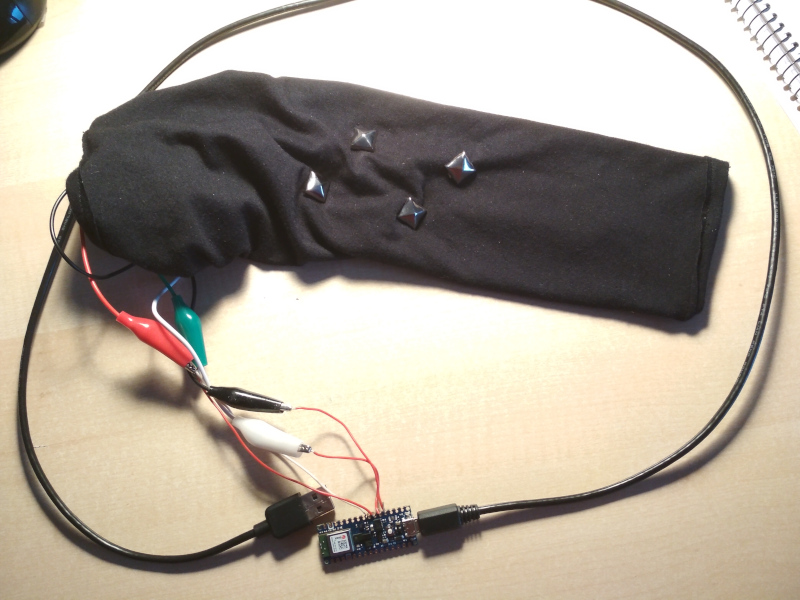

But it can be covered by wrapping around a layer of cloth, turning it into an

inconspicuous fingerless glove:

If you look hard at this picture, you can see the LED of the Arduino glowing

through the fabric, the voltage divider to the right of it, appearing like a

line pressing through the fabric, the ground electrode on the lower right edge

of my palm, and the food crumbs on my laptop :)

The signal seems to be much better, and as I move my arm and hand around, I can

see distinct patterns using the Arduino IDE signal plotter, but for some reason

the neural network doesn't seem to process it as well. Will need some

tinkering. I hope it was not a mistake to leave out the electrodes at the

upper forearm.

I already ordered parts for the next prototype. If all goes well, it's going to

have 33 'trodes using analog multiplexers. The electrodes will be more

professional & comfortable as well. Can't wait!

Data Cleaning

└2021-04-14, by Roman

The arduino

code

now produces samples at a consistent 1kHz. I also moved the serial read

operations of the calibrator software into a separate

thread

so that it doesn't slow down on heavy load, causing the buffer to fill up, and

the labeling to desynchronize. I am once again confused and surprised that I

got ANY useful results before.

I disconnected analog input pin 7 from any electrode, and used it as a baseline

for the other analog reads. By subtracting pin 7 from every other pin, the

noise that all reads had in common was cancelled out. Hope this doesn't do

more harm than good.

I also connected the ground line to one of the wrist electrodes rather than to

the palm, since the palm electrode tended to move around a bit, rendering all

the other signals unstable.

And did you know that the signals looks much cleaner when you unplug the laptop

from the power grid? :p

I'll finish with a video of me trying to play the frustrating one-button

jumping game Sienna by flipping my

wrist. This doesn't go so well, but maybe this game isn't the best benchmark

:D My short-term goal is to finish level 1 of this game with my device.

Multiplexers

└2021-04-15, by Roman

The analog multipexers (5x DG409DJZ) and other stuff arrived! I almost bought a

digital multiplexer, because I didn't know there were various types... But I

think that these will work for my use case. The raw signal that I get out of

it looks a little different, but when I filter out the low & high frequencies

with

TestMultiplexer2.ino,

the direct signal and the one that goes through the multiplexer looks almost

identical =D.

Amplifiers

└2021-04-19, by Roman

I have the feeling that before building the next prototype, I should figure out

some way of enhancing the signal in hardware before passing it to the

microcontroller. It's fun to hook the 'trodes straight to the ADC and still

get results, but I don't think the results are optimal. So these days I'm

mostly researching and tinkering with OpAmps.

First Amplifier Circuit

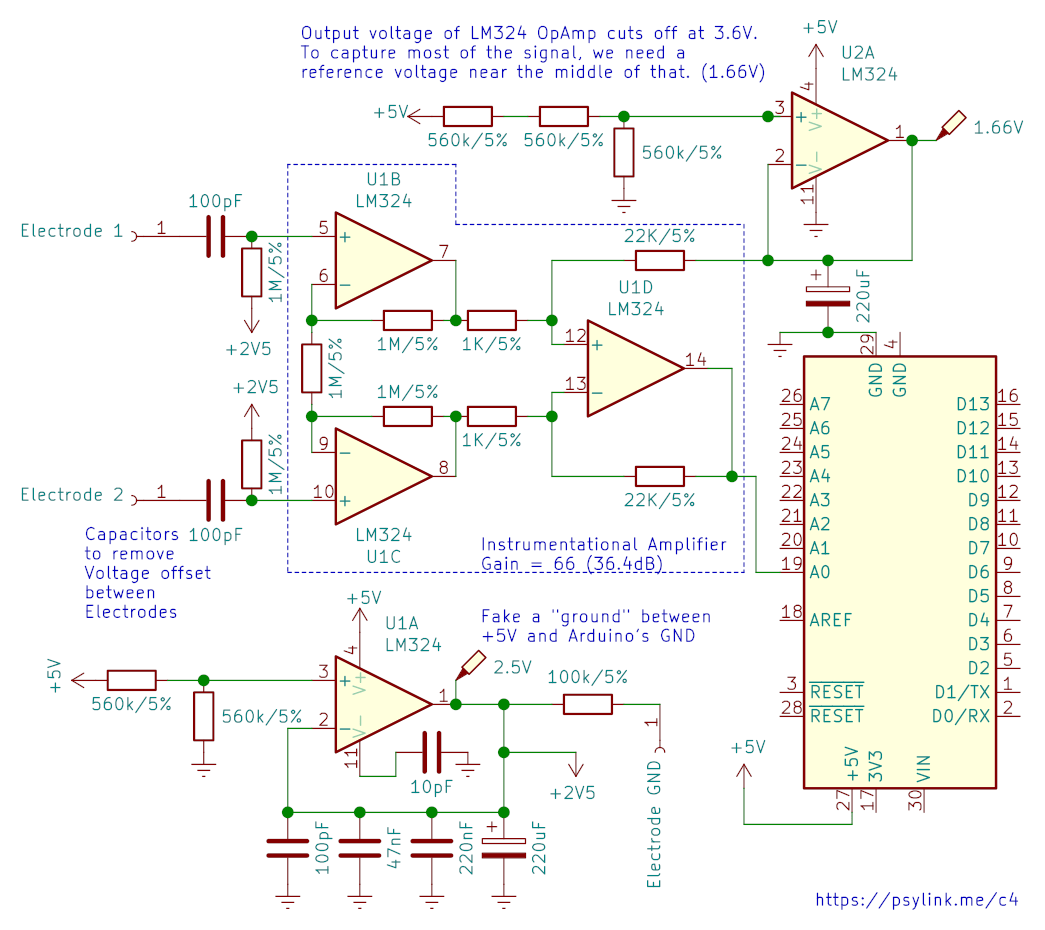

└2021-04-24, by Roman

I had my head stuck in electronics lectures, datasheets, and a breadboard to

figure out a decent analog circuit for amplifying the signal. It sounds so

straight forward, just plug the wires into the + and - pin of an operational

amplifier, add a few resistors to specify the gain of the OpAmp, and feed the

output to the analog input pin of the Arduino... But reality is messy, and it

didn't quite work out like that.

Here's a list of problems:

- The voltage I measured from the electrodes seemed incredibly fragile. As soon

as I wanted to do something with it, it seemed to change. This could be due

to the high impedance of the skin, causing a drop in voltage as soon as one

draws any current.

- One electrode may have a DC voltage offset compared of the other electrode.

When this gets large (~50mV+), the amplified voltage difference gets off the

scale.

- The OpAmp amplifies not just the signal but also the noise, like:

- I ordered a part that requires min. +/-2.25V. The Arduino supplies 3.3V, so

all is well, right? Nope. It means that I need negative 2.25V as well as

positive 2.25V.

- Solution: Increased the voltage of the entire circuit to 5V, which

the Arduino conveniently supports by changing a solder jumper. The

middle-ground reference voltage rose from 1.65V to 2.5V, leaving enough

room for the required +/-2.25V. I don't actually use the part yet, but I

wanted to prepare for it.

- The 2.5V reference voltage from the voltage divider

strongly fluctuated, messing up the output from the OpAmp.

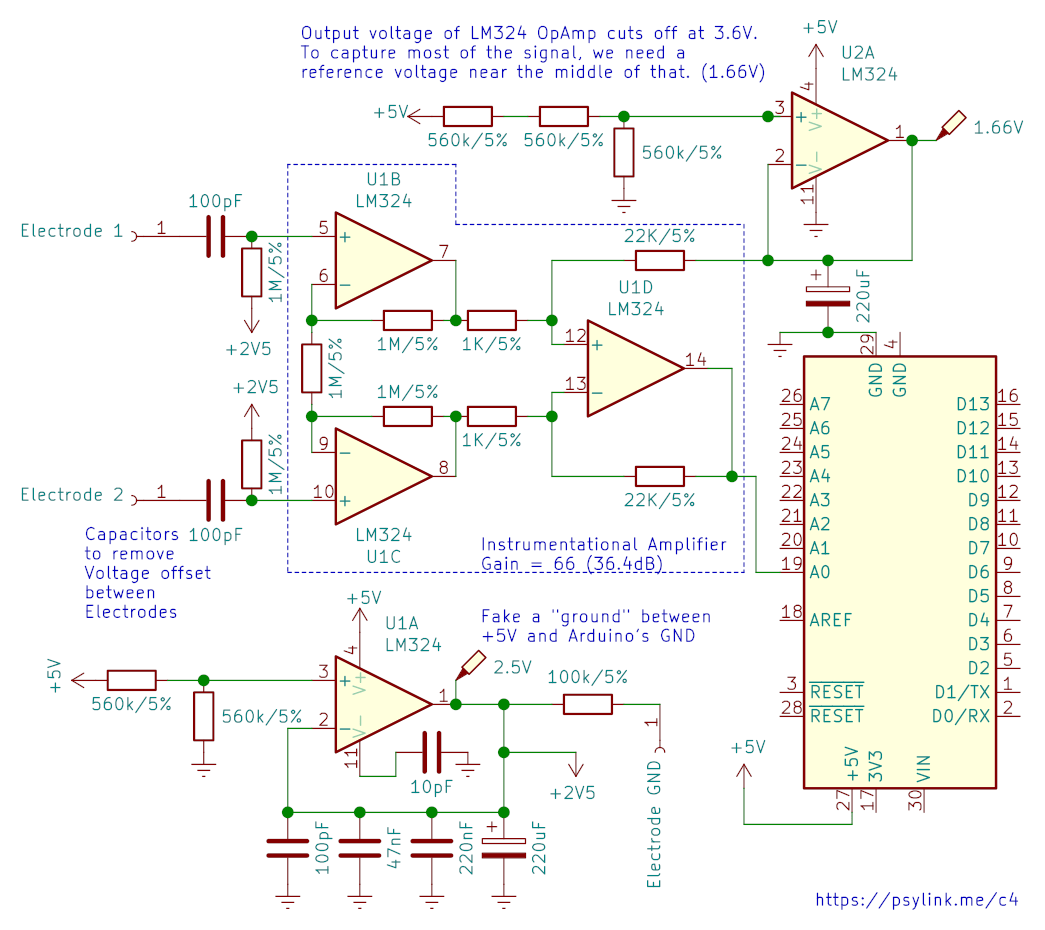

- The LM324N OpAmp that I used has an output voltage limit of 3.6V (at a supply

voltage of 5V.) That cuts off a good chunk of the signal.

- Solution: I added a second reference voltage at 1.66V so the output

centers around that. (Conveniently, the output limit of 3.6V is close to

the Arduino's ADC reference voltage of 3.3V.)

- Should I even do any of this? I'm limiting the neural network by introducing

my bias about what a clean signal looks like. Any circuit will invariably

filter out certain information, enhance other information, and add irrelevant

noise. How do I know that the information that I filter out (e.g. the DC

offset voltage between electrodes, or even what I consider irrelevant noise)

isn't useful to the neural network?

- Solution: Keep the signal processing reasonably minimal

I also connected the electrode signal to ground with a 1MΩ resistor which

greatly improved the signal, and I have no idea why.

One peculiar thing I noticed was that the signal seemed stronger when my laptop

was connected to the power supply. It superimposed noise, but also seemed to

increase differences in electrode voltages. I don't quite understand this yet,

but 2 things follow from that:

- For replication purposes, I'm using a Lenovo Thinkpad T460p switched to the

Intel GPU, which creates it's own particular noise patterns, even when

unplugged from the grid.

- I should try out modulating the ground electrode voltage with a controlled

low frequency pattern to see if this improves signal to noise ratio. Ideally

<30Hz or >500Hz so I can easily filer it out later.

Some of the references I used:

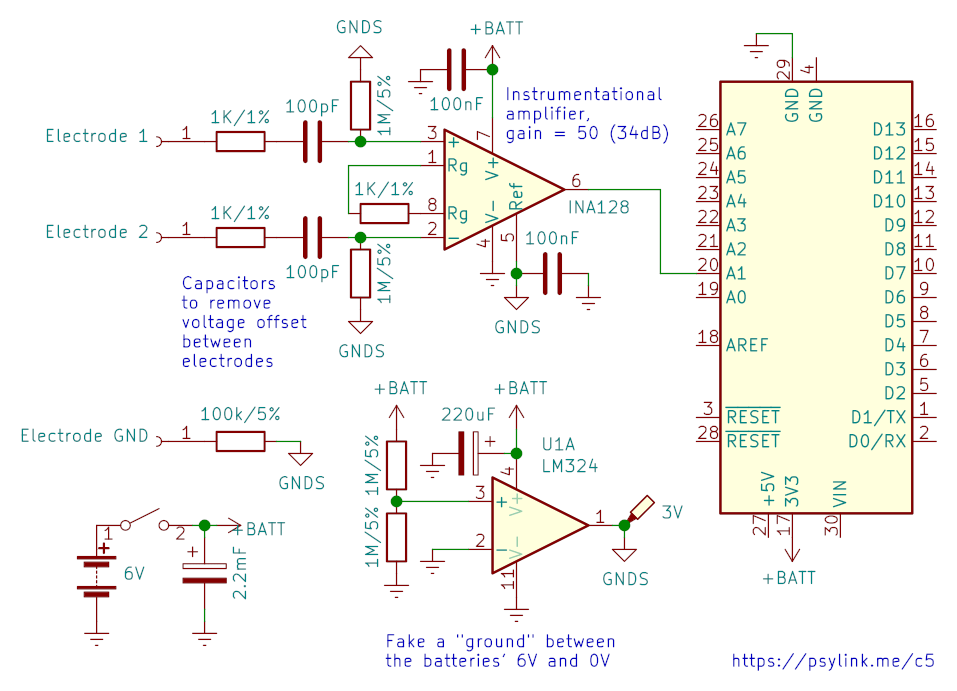

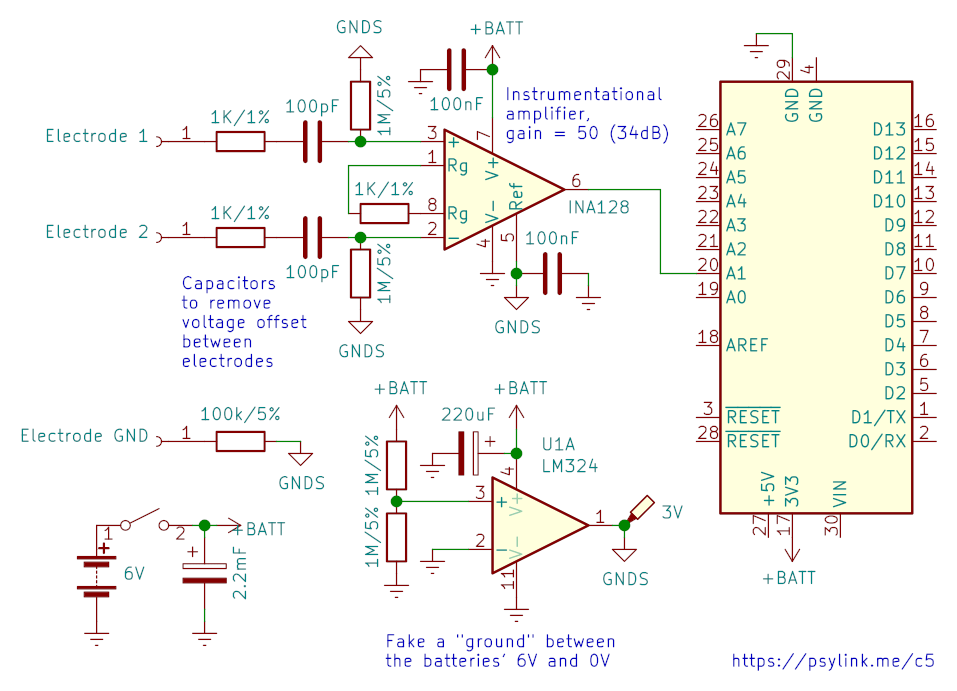

The resulting circuit:

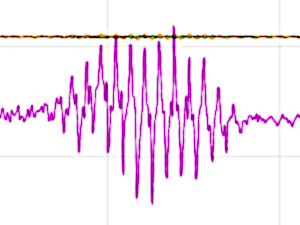

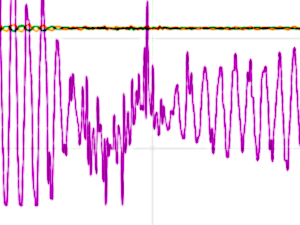

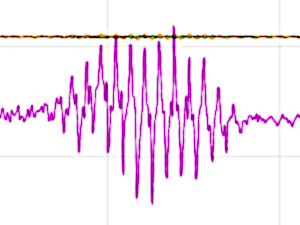

And the signals look like:

Yellow and green are two electrodes, right after their respective OpAmp, and purple is (yellow-green)*20.

This should be good enough to move forward, but I bought some INA128 instrumentation amplifiers and perhaps I will tinker some more to get an even better signal. Can't wait for the next prototype though :).

In other news, I watched Dr. Gregory House explain forearm muscles, so next time my electrode placement will be better than random!

And since I learned KiCad for creating the above schematic, I thought I'd add schematics for the previous models as well, see circuits.

Going Wireless

└2021-04-28, by Roman

I've been battling with reducing the power line noise for too long, so I

thought screw it, let's go off the power line entirely. I put the circuit on

two 3V CR2032 coin cells and wrote

some code

to transmit the signals via BLE (Bluetooth Low Energy) using the

ArduinoBLE library.

Since I can not plot the signals via the Arduino IDE plotter anymore, I

switched to GNURadio and wrote a plugin that

establishes the BLE connection and acts as a signal source in the GNURadio

companion software

My new "electrodes" also arrived: Simple prong snap

buttons.

They don't have sharp edges like the pyramidal studs I used before, and allow

me to easily remove the wires from the electrodes and plug them in somewhere

else as needed.

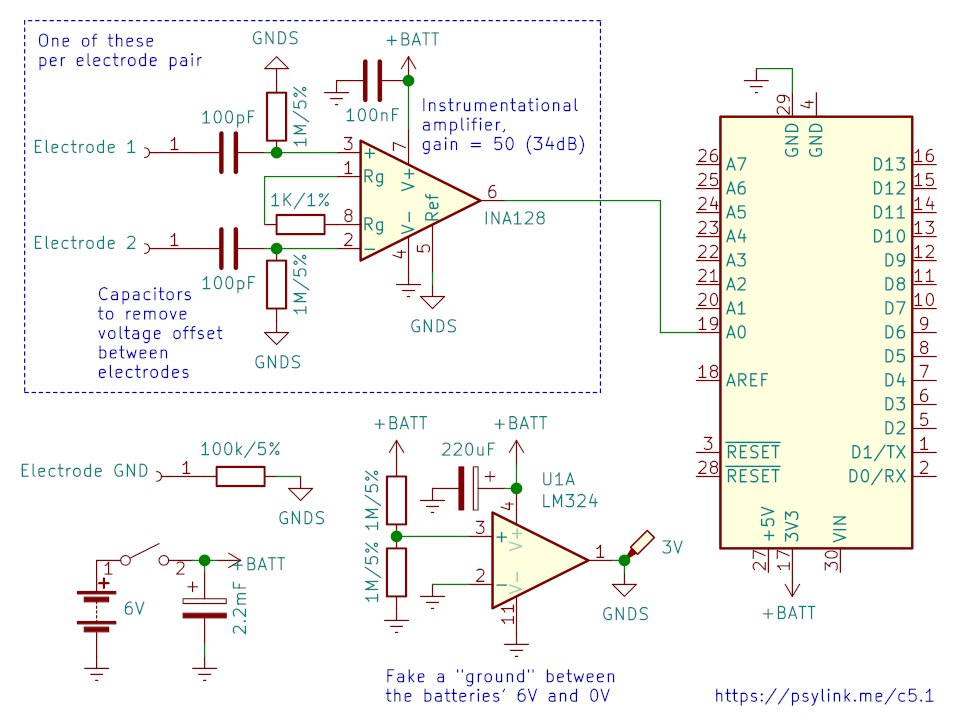

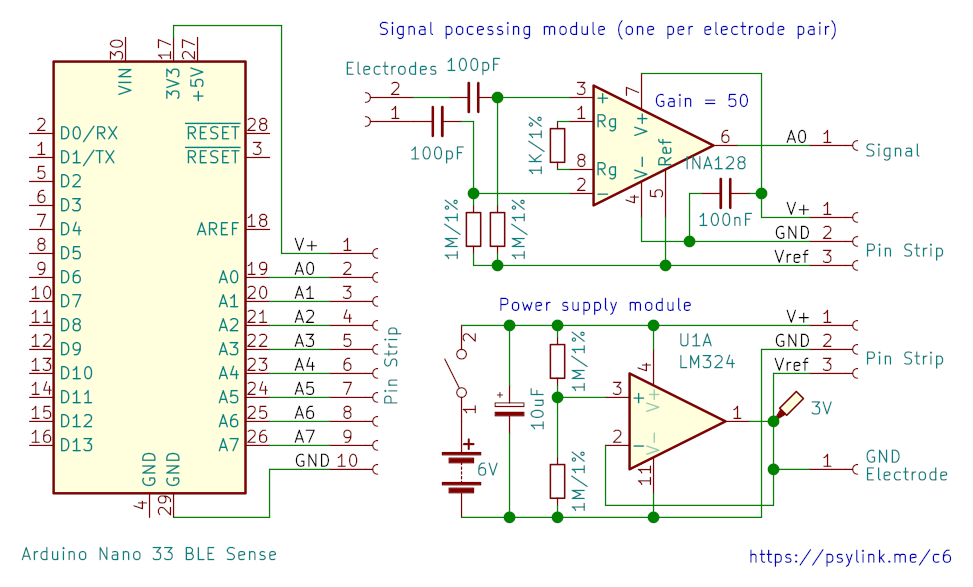

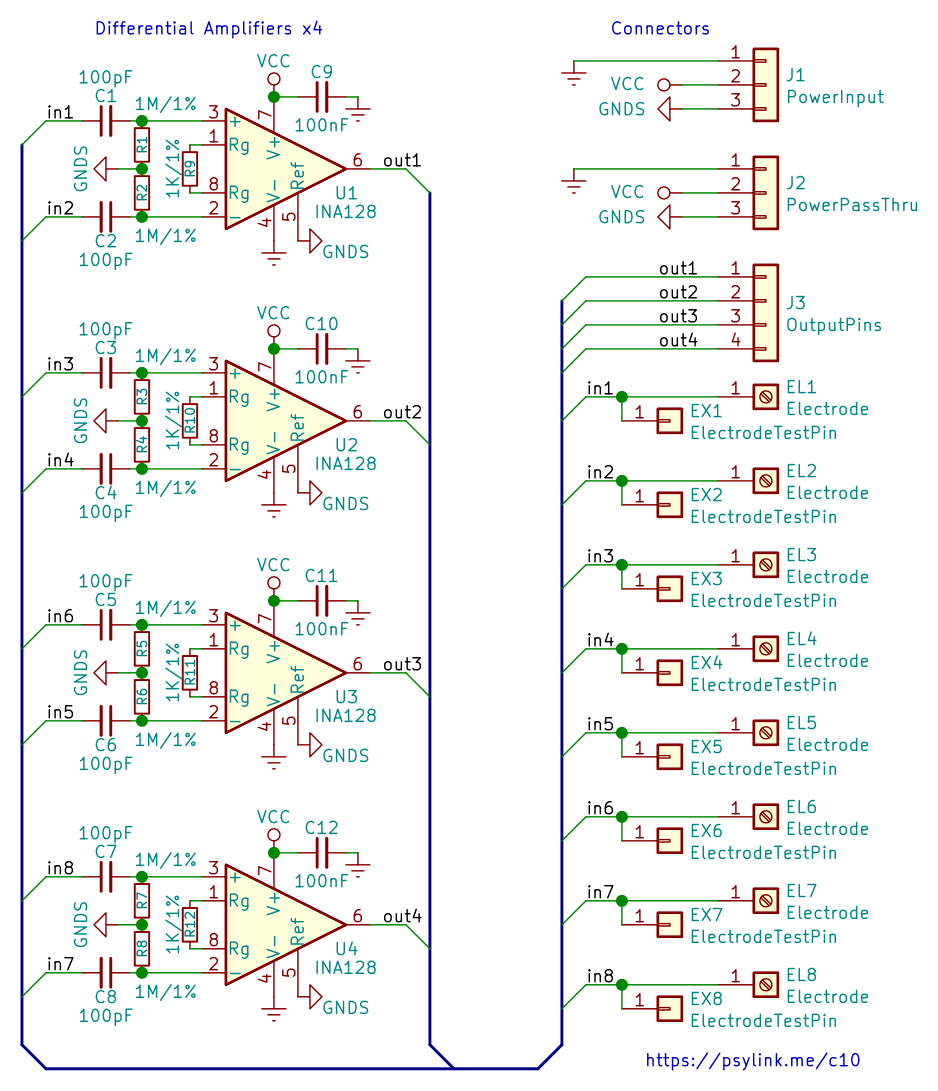

I also employed INA128 instrumentation

amplifiers, drastically reducing the

complexity of the circuit. It's a tiny SMD chip, which I plan to embed in hot

glue, along with the 3-4 capacitors and 3-5 resistors required for

processing/de-noising, and place 8 of these processing units across the

glove/wristband, connected to two electrodes each.

Now I'm battling the problem that I can only get about 1kB/s across the ether.

How am I supposed to put 12kB/s worth of signal in there? (8 channels,

1k samples/s, 12 bit per sample) Let's see if I can find some nice compression

method, but I fear that it's going to be lossy. :-/

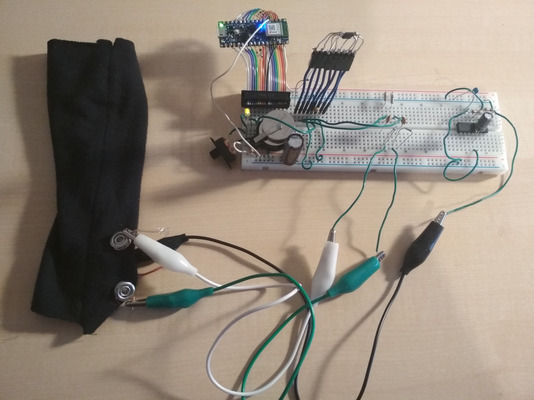

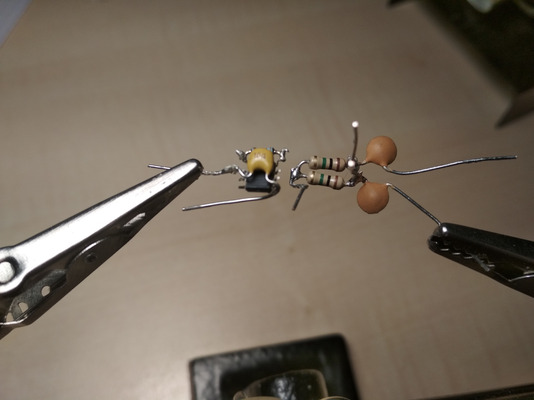

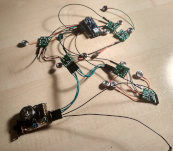

Soldering the Processing Units

└2021-04-29, by Roman

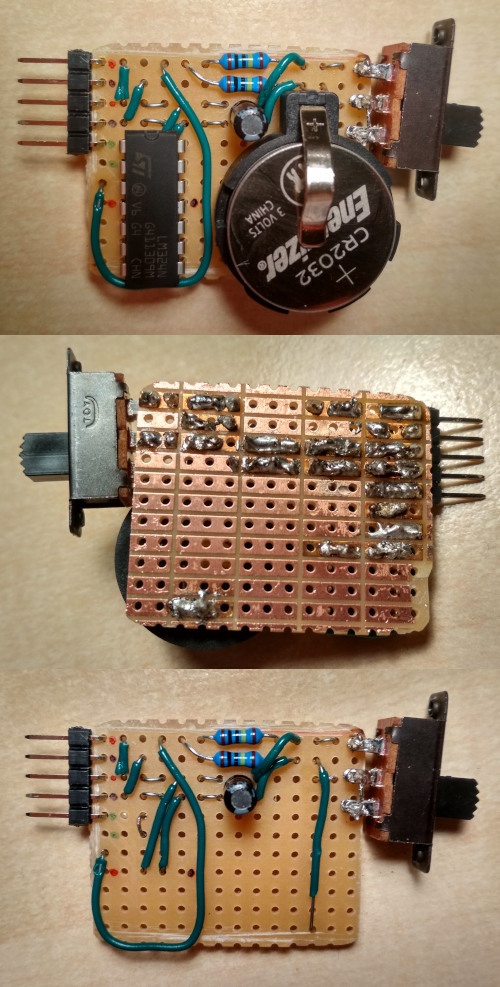

The plan was to split the circuit into:

- 1 central part including the Arduino, power supply and the OpAmp that

generates the signal ground, and

- 8 distributed signal processing units, embedded in hot glue for stability and

electrical insulation, consisting of an instrumentation amplifier and related

components, close to the electrodes to avoid signal degradation.

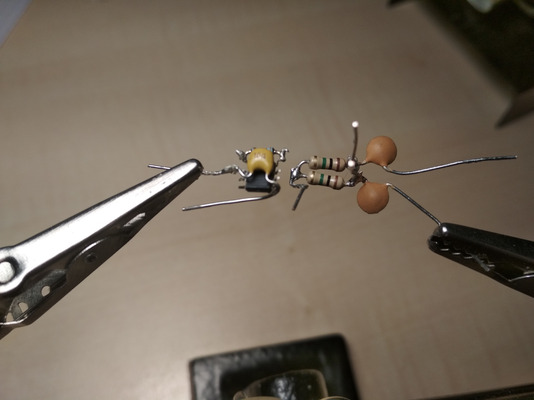

Here's my try to solder one of those units:

This took me over an hour, during which I began questioning various life

choices, started doubting this whole project, poured myself a Manhattan

cocktail, wondered how long it would take to complete all eight of these,

whether it will even be robust enough to withstand regular usage of the device

(NO, IT WON'T), and how I'm going to fix the inevitable broken solder joints

when the entire thing is in fucking hot glue...

I gave up, and now my plan is to get

PCBs for this instead.

I have little experience with this, so I've been putting it off, but how hard

can it be?

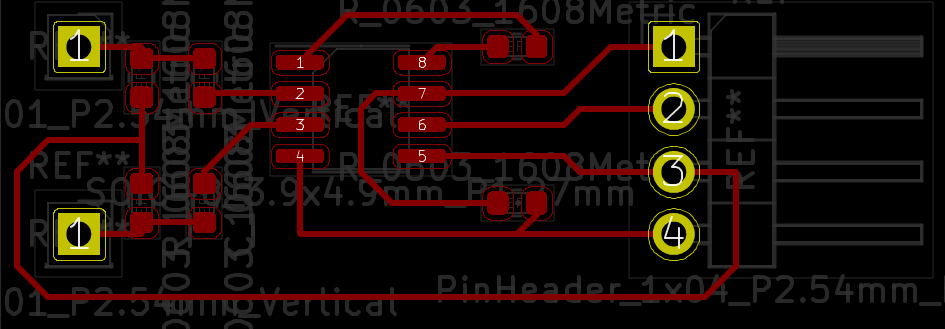

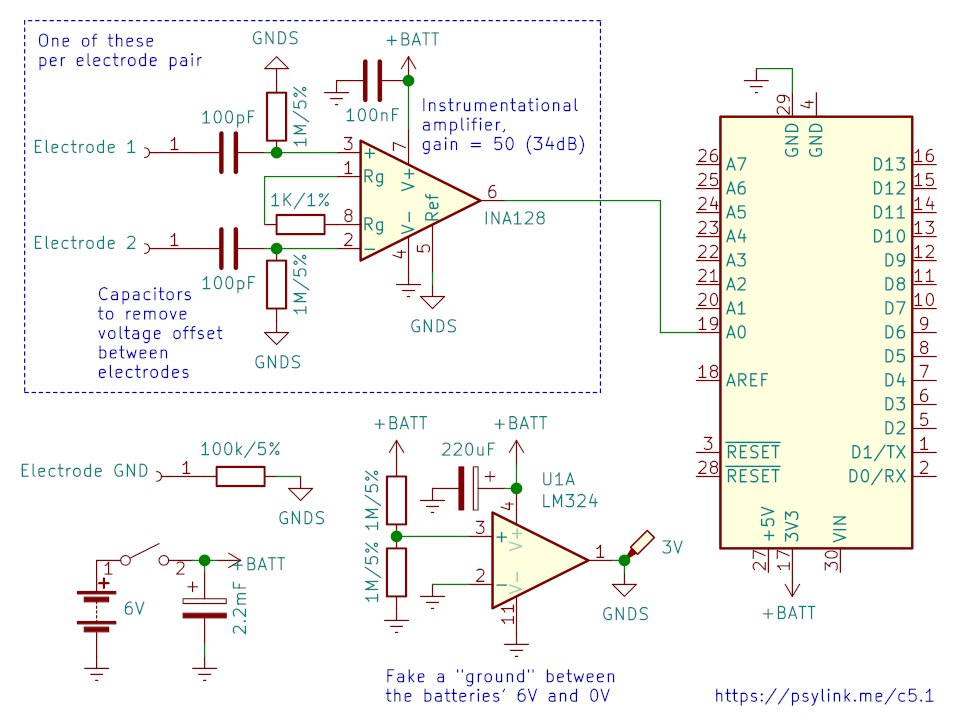

First draft:

Updated schematic:

I removed the decouplying capacitor between ground and GNDS (signal ground) by

the REF pin of the INA128 because mysteriously it made the signal worse, not

better. Also removed the 1K resistors between electrodes 1+2 and the

respective capacitors, because they served no apparent purpose.

Also, I was frustrated that GNURadio doesn't allow you to get a "rolling" view

of a signal. The plot widget buffers as many samples as it can show, and only

when the buffer is full, it updates the graph, clears the buffer and waits

again.

I wanted instant updates as soon as new samples are in, and as a quick&dirty

workaround I wrote a

GNURadio shift block

which keeps filling up the buffer of the plotting widgets.

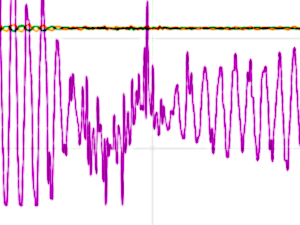

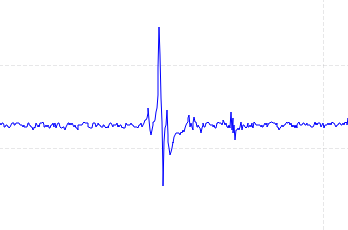

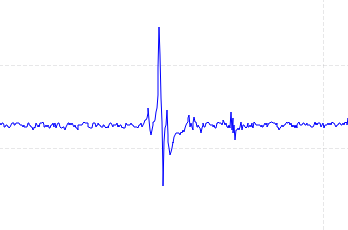

I'll finish with a nice picture of a finger snap, as recorded with one

electrode pair on my dorsal wrist. Click to enlarge and view the frequency

domain as well. (Just one electrode pair because that's all I can squeeze out

of the poor bluetooth low energy bandwidth so far)

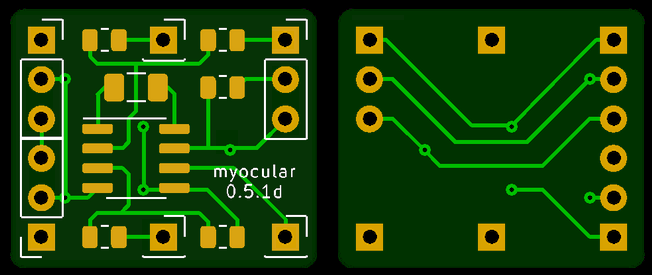

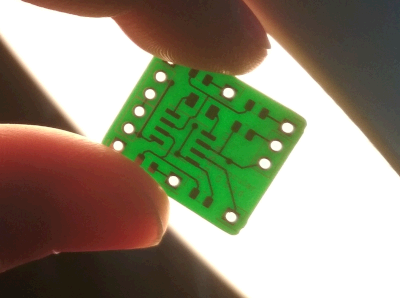

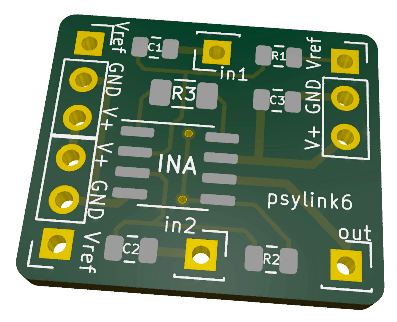

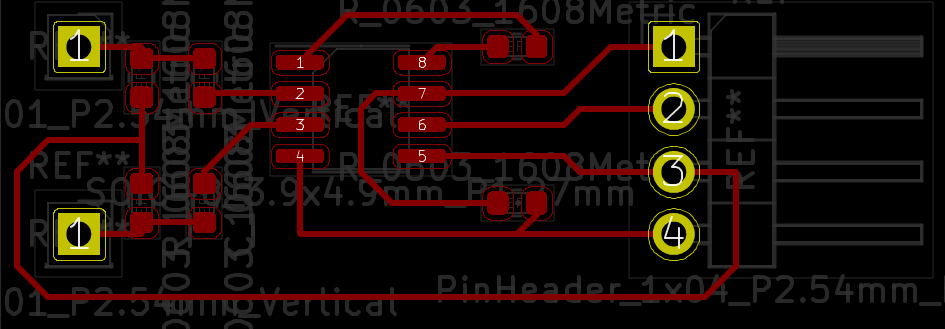

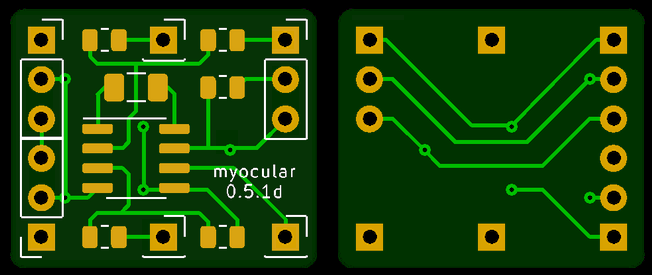

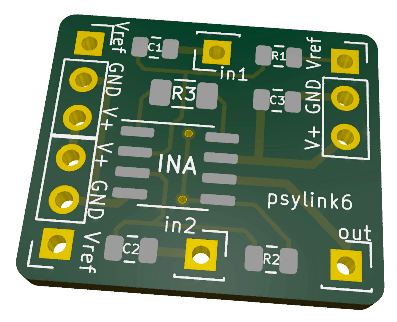

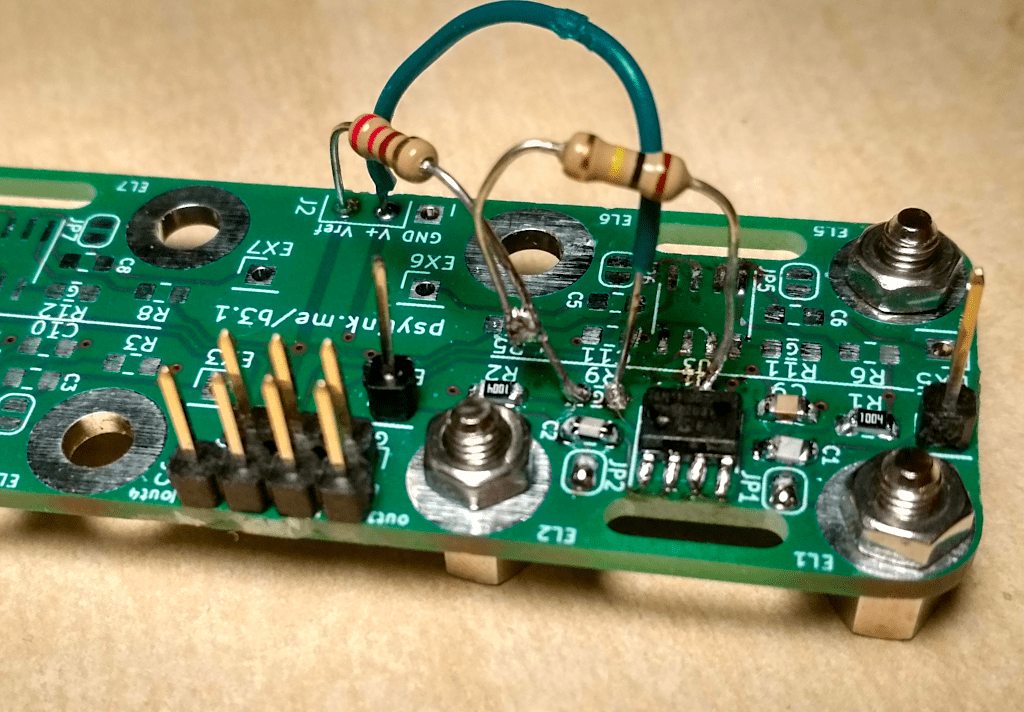

PCB Time

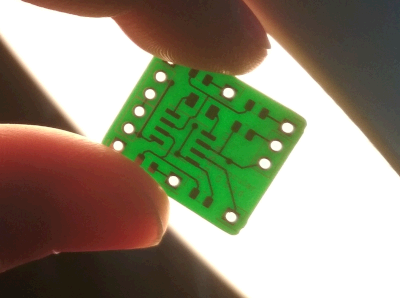

└2021-04-30, by Roman

Today I made a new version of the PCB that processes the signals from one

electrode pair:

Actually, several versions. This is the 4th iteration, and let's not even look

at the previous ones because they were just plain wrong. I stared at this

design for a long time though and couldn't find another problem, so I went

ahead and ordered 30 pieces of it. Can't wait to find out in what way I messed

up :'D And hey, maybe it'll actally work.

Main features:

- Dimensions: 20x17x1.6mm, rounded corners

- Tiny enough to fit between 2 electrodes!

- 2 connectors for electrodes, at the middle top & bottom

- 1 connector for the output at the bottom right corner (on the front side. The back

side is mirrored)

- 3 power line connector ports on the other corners, with 3 pins each:

- The signal reference voltage

- Ground

- +6V from the battery

- 3 capacitors, 3 resistors, 1 integrated circuit

To avoid having a kilogram of cables on the device, this board supports wiring

in a mesh network topology,

where the boards share the power lines amongst each other using the redundant

power line connector ports. One board can power two other boards, which in

turn can power 4, and so on.

The bypass capacitor between ground and V+ will hopefully keep the voltage

stable, though I'm a bit worried about the reference signal. If necessary, I

can "abuse" the reference signal pin of the power line connector ports to add

extra ground electrodes. I considered adding an extra opamp on every board to

generate a fresh reference voltage but that would make the circuit too big for

my taste.

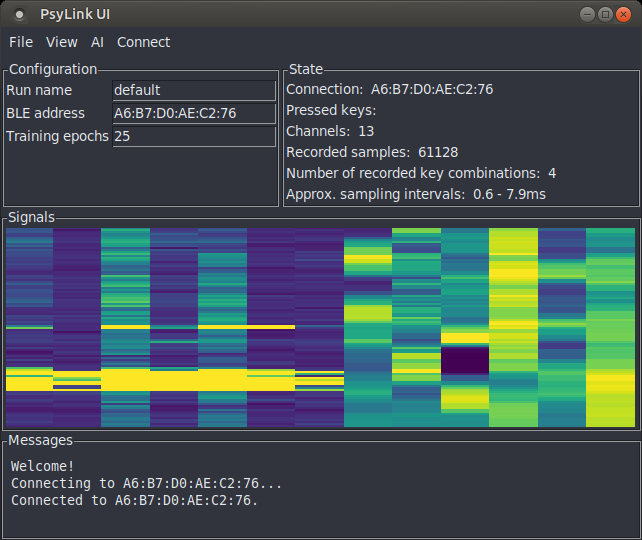

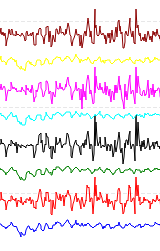

Higher Bandwidth, new UI

└2021-05-04, by Roman

Hah, I managed to raise the Bluetooth bandwidth from ~1kB/s to 6-7kB/s with this one magic line:

BLE.setConnectionInterval(8, 8);

It raises the power consumption by 4% (3.5mW), but that's totally worth it. I

can now get all 8 channels in 8-bit resolution at 500Hz across the aehter.

Eventually I should aim for 10-bit at 1kHz, but I think that can wait.

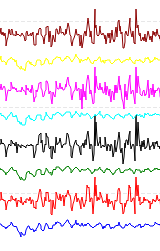

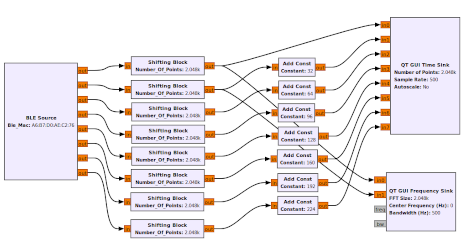

This is the GNURadio flowgraph

and the resulting output. (I only have hardware for 2 electrode pairs, so

even-numbered and odd-numbered signals are wired to the same input. Still

waiting for the PCBs.)

Power ratings:

- No Bluetooth connection: 86.9mW (16.9mA x 5.14V)

- Transmitting at 1-2kB/s: 88.9mW (17.3mA x 5.14V)

- Transmitting at 6-7kB/s: 92.5mW (18.0mA x 5.14V)

Surprisingly to me, the LEDs were draining a good chunk of the power, and I

saved 16mW by removing the external power LED (see previous

photo) and by

PWM-dimming

the blue LED that indicated Bluetooth connections. It gives me approximately 15

hours run time with 2x CR2032 coin cells.

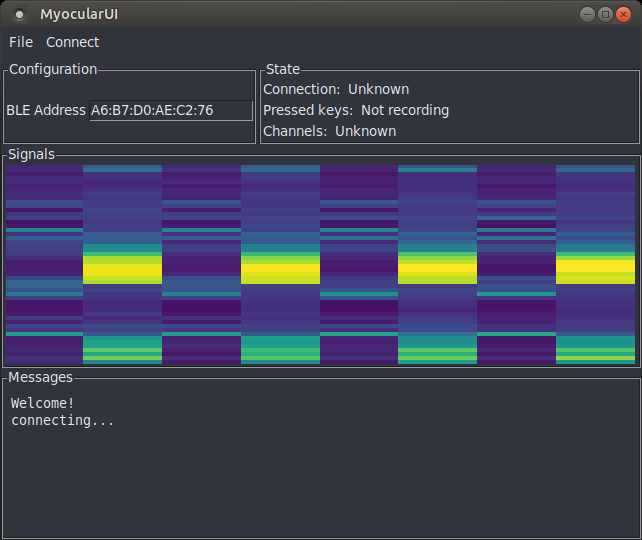

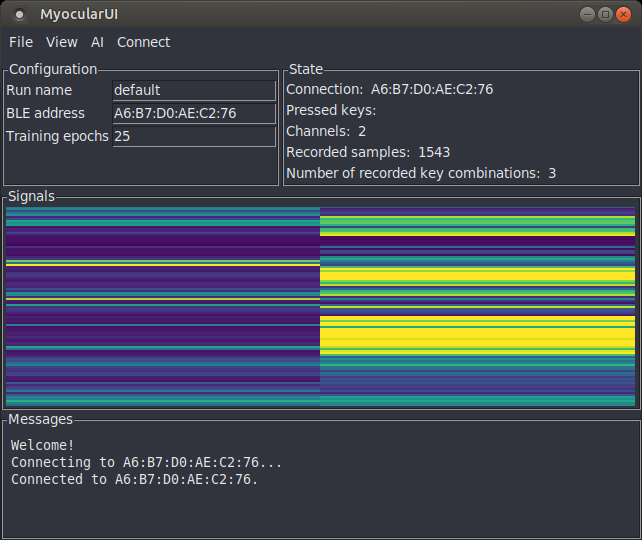

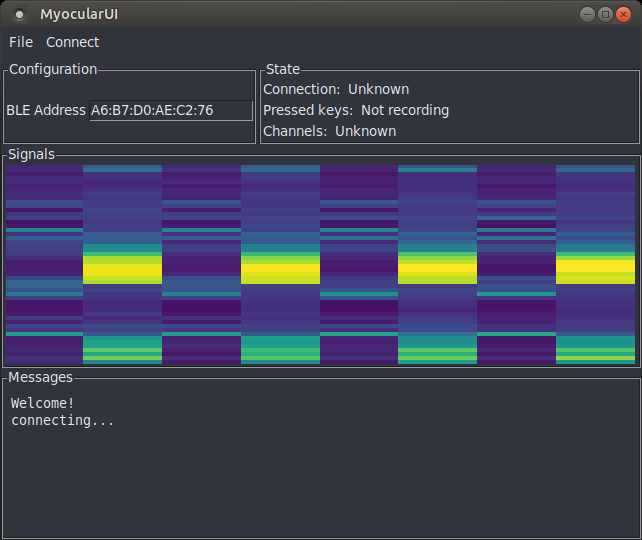

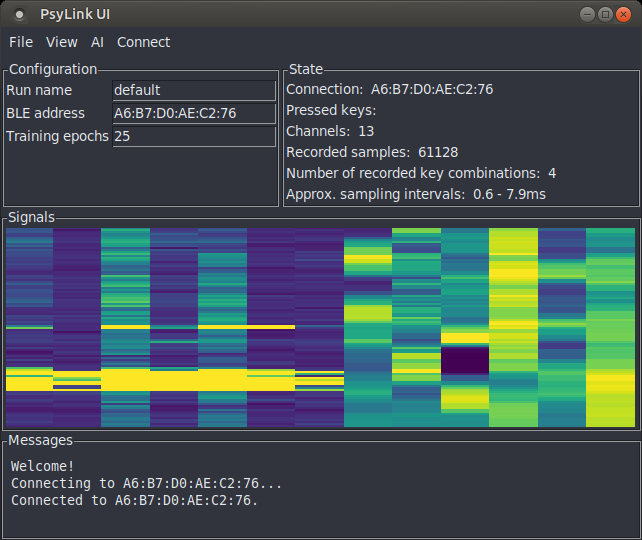

Also I'm in the process of rewriting the UI:

The colorful column graph is a live visualization of the signal. The columns

correspond to electrode pairs, while the rows are time frames. The top row

shows the amplitude of the signal at the current time, and the rows flow

downward, allowing you to view changes back in time, as well as correlations

between signals.

You'll also be able to change settings on the fly, view the status of e.g. key

recordings or machine learning processes, and more. All of this is in a

modular library

that will also be usable from e.g. GNURadio.

I was thinking of changing the graphical user interface toolkit from Tkinter to

a more modern one, because Tkinter looks a little shabby, and it has problems

determining which keys are currently pressed, but I decided against it, because

I made the experience of being unable to run my own software several years

after writing it because the exact version of the GUI toolkit, along with all

dependencies, was too annoying to set up. Tkinter has been around for decades

and will probably stay, so I'll stick with it for now. Also, I can easily

solve the key pressing issue with an external key tracking library like

pynput.

Can't wait to try out the new UI with 8 individual electrode pairs, once the

PCBs arrive! (assuming they work :'D)

Finished new UI

└2021-05-06, by Roman

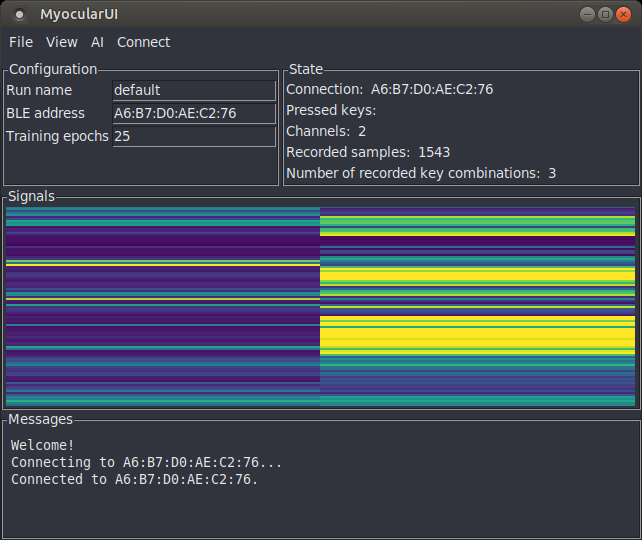

The new user interface now supports all previous features!

- Capturing muscle signals

- Capturing the keys that the user is pressing

- Training a neural network to predict key presses from given signals

- Auto-pressing keys based on incoming signals using said neural network to

predict which keys the user wants to press

It's sooo much more pleasant to have a direct view on the state of the

application and an instant visualization of the signals. The previous version

was literally just a blank window, with a single menu called "File" that

contained all the actions. :D I never even bothered to upload a screenshot,

but here's one for documentation purposes:

Also, this time I used clean & efficient data structures to make the code

easier to work with, a more reliable key capturing library

(pynput), and threads to prevent one

activity from blocking the others. The signals obviously go via Bluetooth

instead of a wired serial connection.

I'm also thinking of changing the name for the project, since people are

reading it as "my ocular" rather than recognizing the neologism made of "myo"

(for "muscle") and "ocular" (from "eye"). But all the good names are taken, of

course. -_-

New Name

└2021-05-07, by Roman

After some brainstorming, I changed the working title of this project from

Myocular to ✨PsyLink✨. The close second favorite was FreeMayo (thanks to

Vifon for the suggestion). Free as in free speech/software/hardware, and mayo

as a play on myo (ancient greek for "muscle"). But somehow I liked PsyLink

more. It's inspired by the Psionic

Abilities from the

1999's game System Shock 2.

FYI, this is the list of words that I considered, although unfortunately many

of the coolest combinations were taken:

- axon

- coil

- cortex

- cyber

- free

- gauntlet

- glove

- link

- loop

- magic

- mana

- mayo

- myo

- open

- pipe

- plug

- psi

- psionic

- psy

- psyber

- scan

- surge

- tron

- ware

- wave

- wear

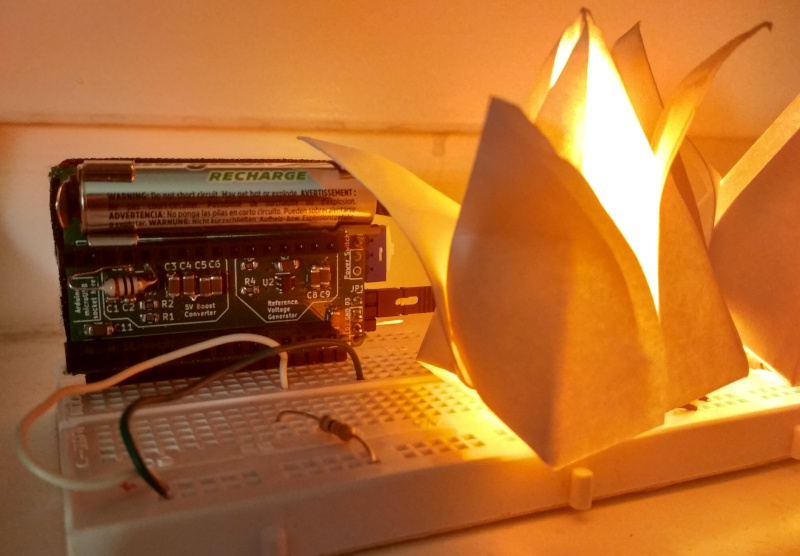

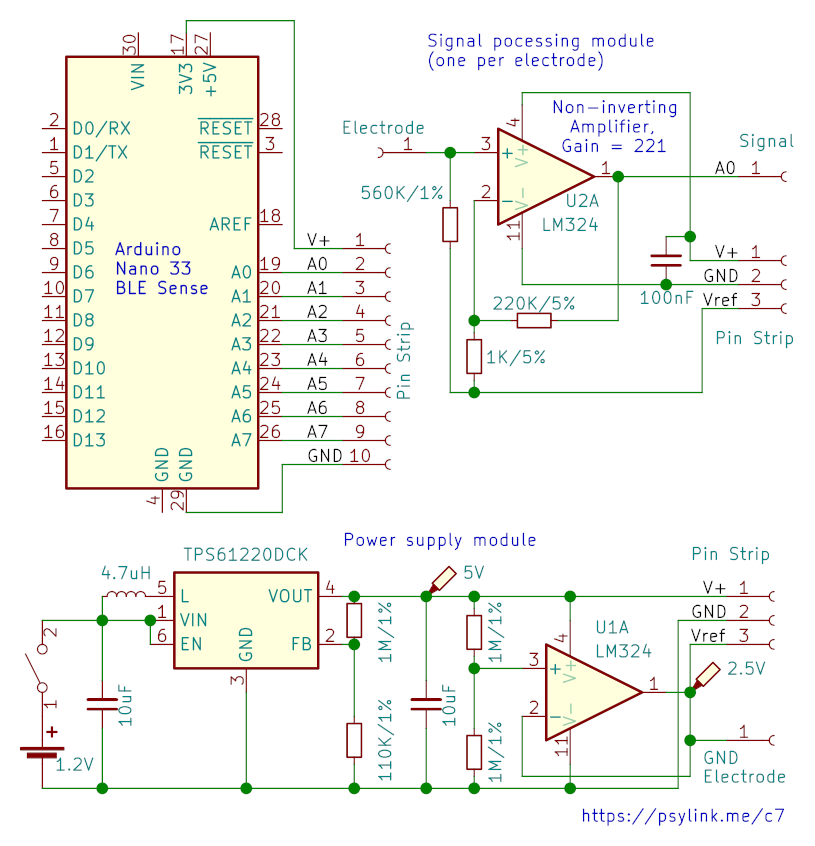

Power Supply Module

└2021-05-09, by Roman

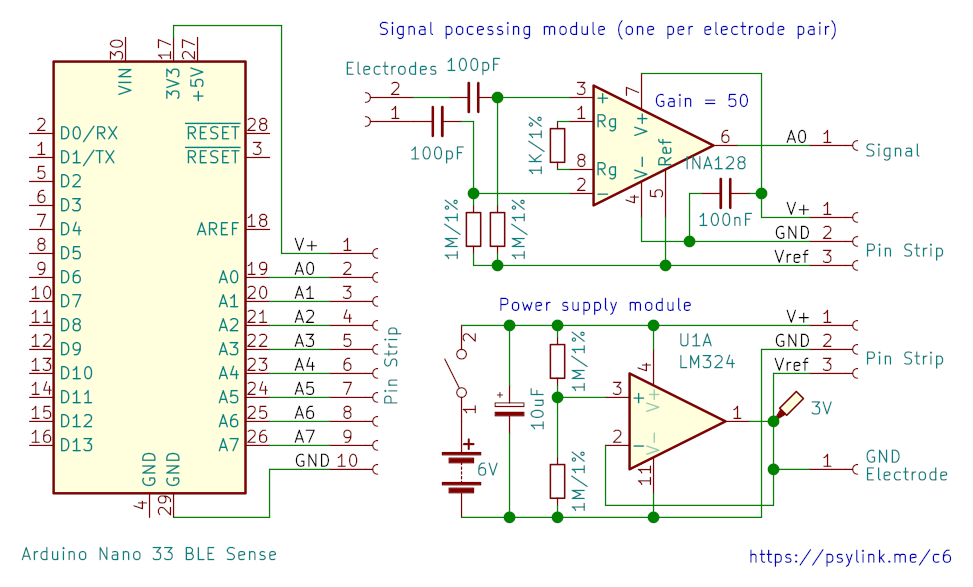

I made an updated schematic (circuit 6) that shows more clearly how the modules

are connected. Also corrected an error with the feedback of the voltage

follower, and changed values of some resistors/capacitors:

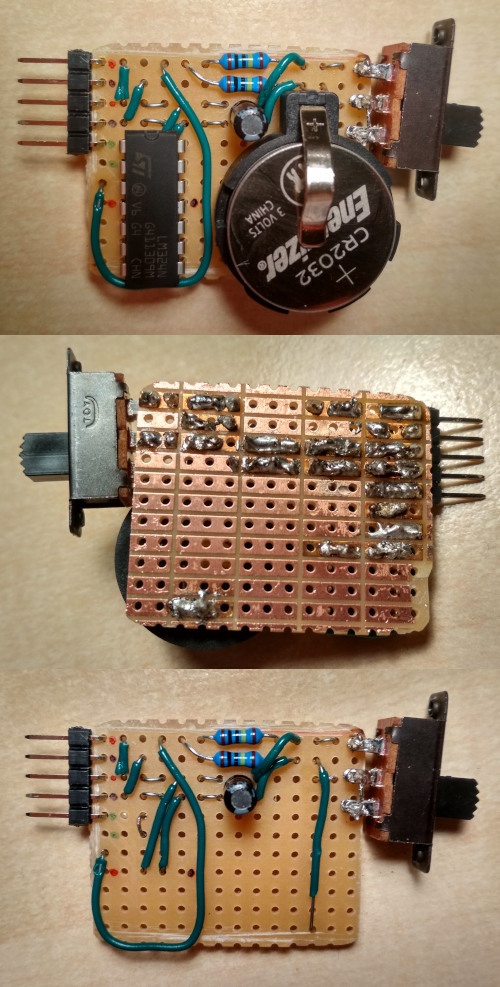

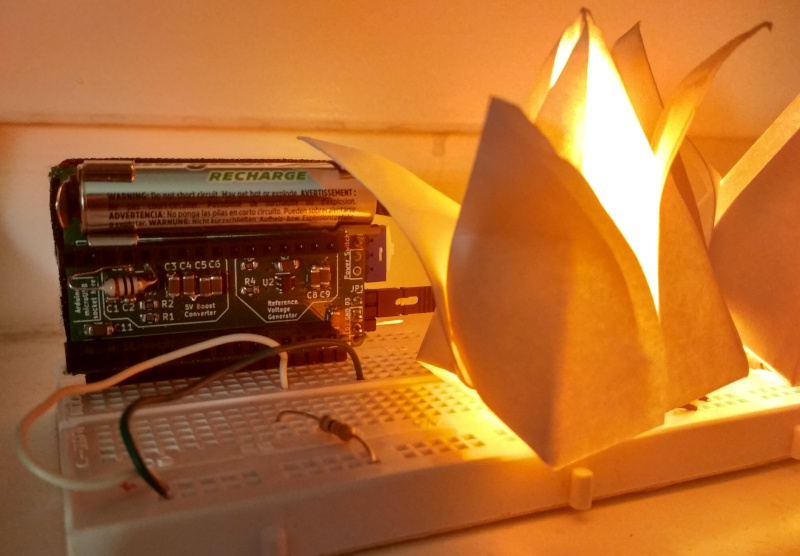

I also constructed the power supply module:

but for some reason it didn't work. All the parts seemed to have been connected

the right way, I couldn't find a short circuit, but the output voltage was

~0.5V instead of ~5V, and the reference voltage was just 0. I blame a possibly

broken opamp.

Well, I didn't like the design and length of the circuit board anyway, so it

didn't hurt trashing the thing and building this beauty instead:

I'll use female-to-female jumper wires to connect V+ and GND to the arduino,

and 3 more wires to bootstrap the power supply of the mesh network of the

signal processing modules.

Notes:

- Yep, that's 2 coin cells in there

- Outputs: Black=Ground, Red=V+, Green=V+/2 (reference signal)

- There's an optional second green pin for the ground electrode

- If you're wondering why I'm using a big ass quad opamp when I just need a

single output: I don't have a smaller one atm.

- I totally need to move this to a SMD PCB in the long run, this is still too

bulky, but will do for now. It's about the dimensions of a 9V battery.

I wonder if some 深圳人 will read this, shake their head, and view me as

a primate struggling to make fire with sticks. That's what it felt like

to construct this thing anyway. Nevertheless, I'm one step closer to the next

prototype :)

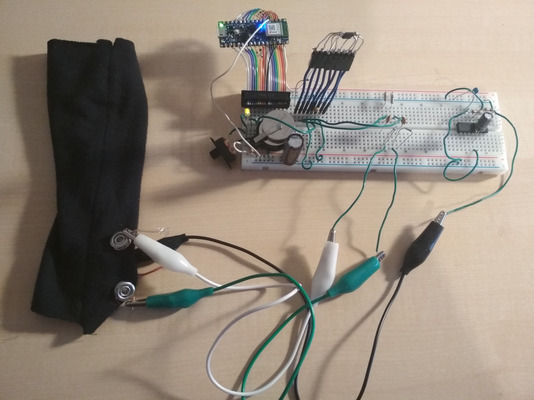

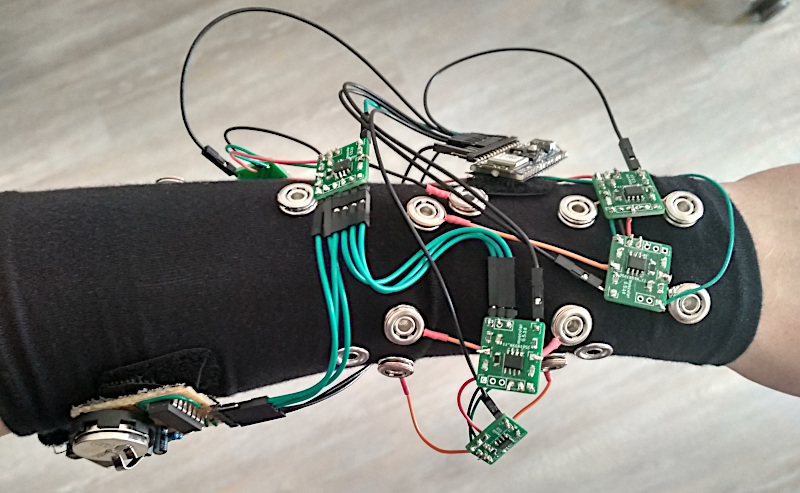

Wireless Prototype

└2021-05-14, by Roman

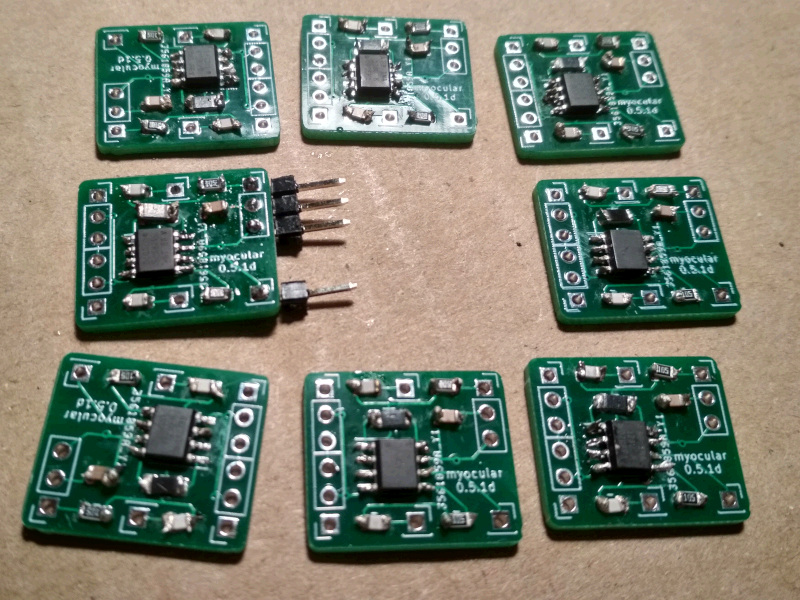

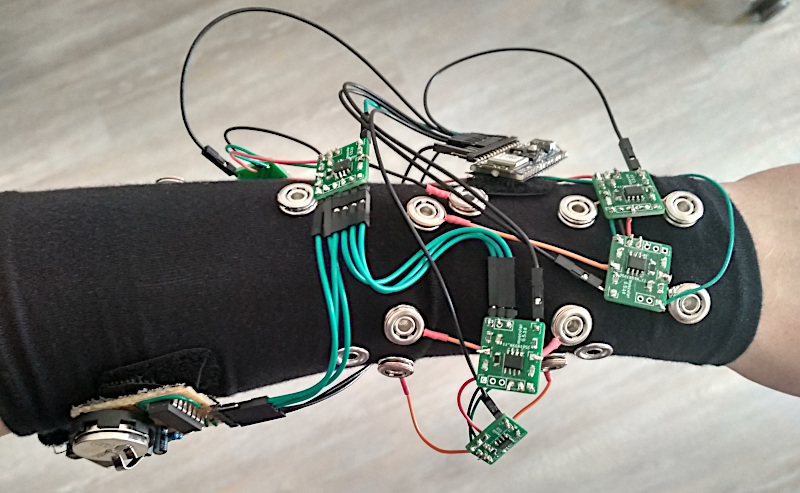

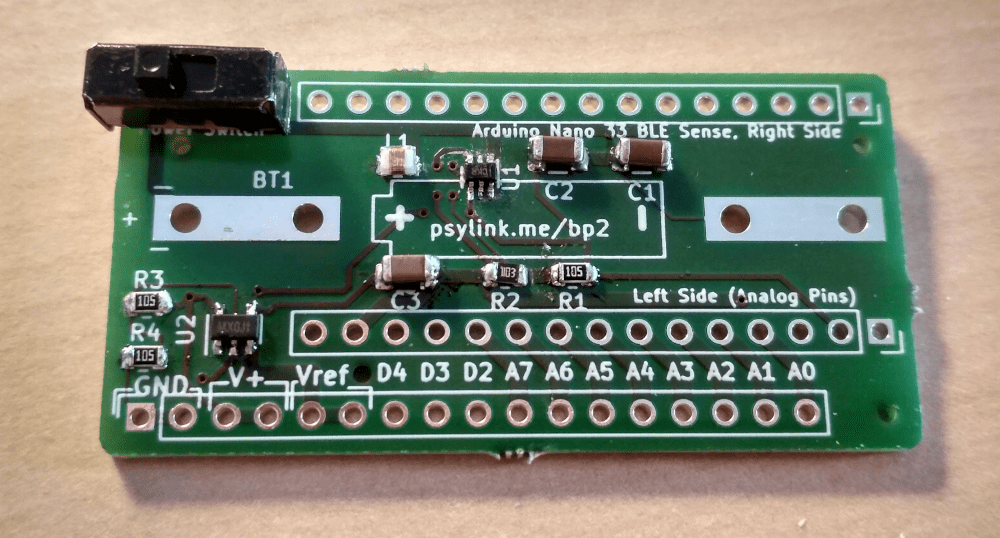

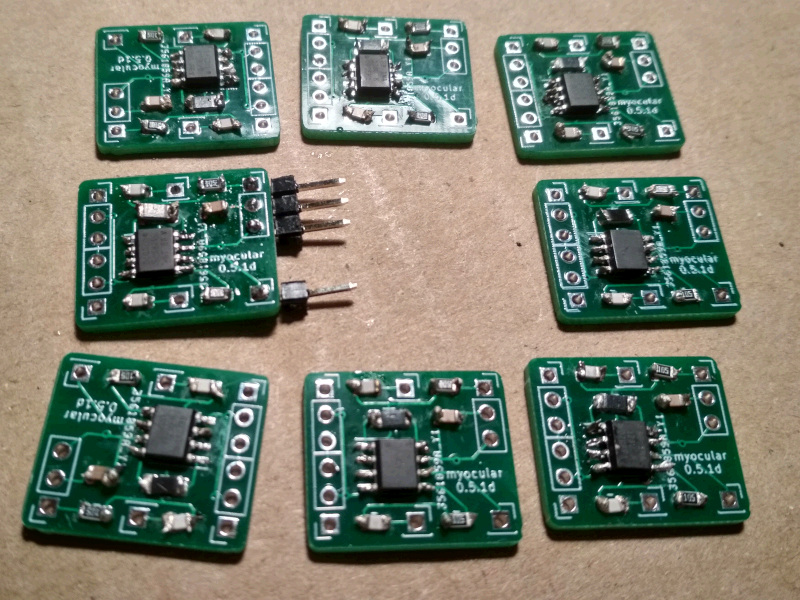

Hell yeah! The PCBs arrived:

Soldering & Sewing

I never soldered such tiny SMD parts before, and didn't have proper tools, way

too thick soldering tin and solder iron tip. I was also too impatient to order

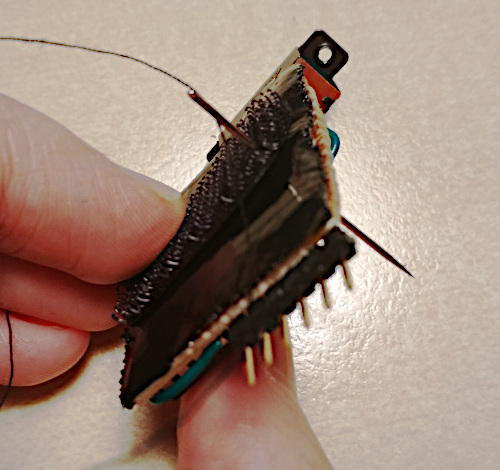

some, so after hours of torture, I produced this batch:

The new prototype was to be a forearm sleeve of modal fabric once again, with

snap buttons for electrodes which will also hold the signal processing PCBs in

place.

But how to attach the Arduino and the power supply module to the sleeve? I

thought, "why not Velcro?" (hook-and-loop fastener) and started sewing it to

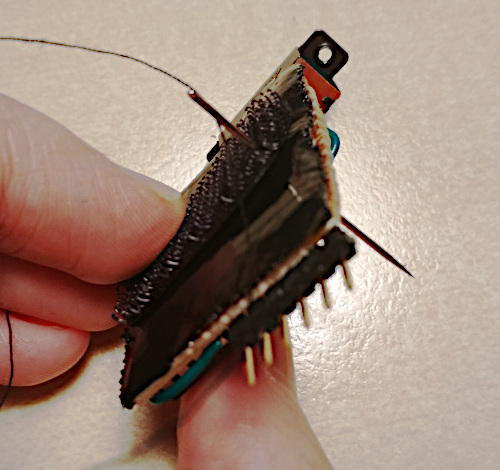

the circuit boards:

(Yes, doing it felt as weird as it looks)

So I sewed the sleeve, assembled one electrode pair along with its processing

PCB, and wired everything together. Here's me being overly excited about the

first wireless test run:

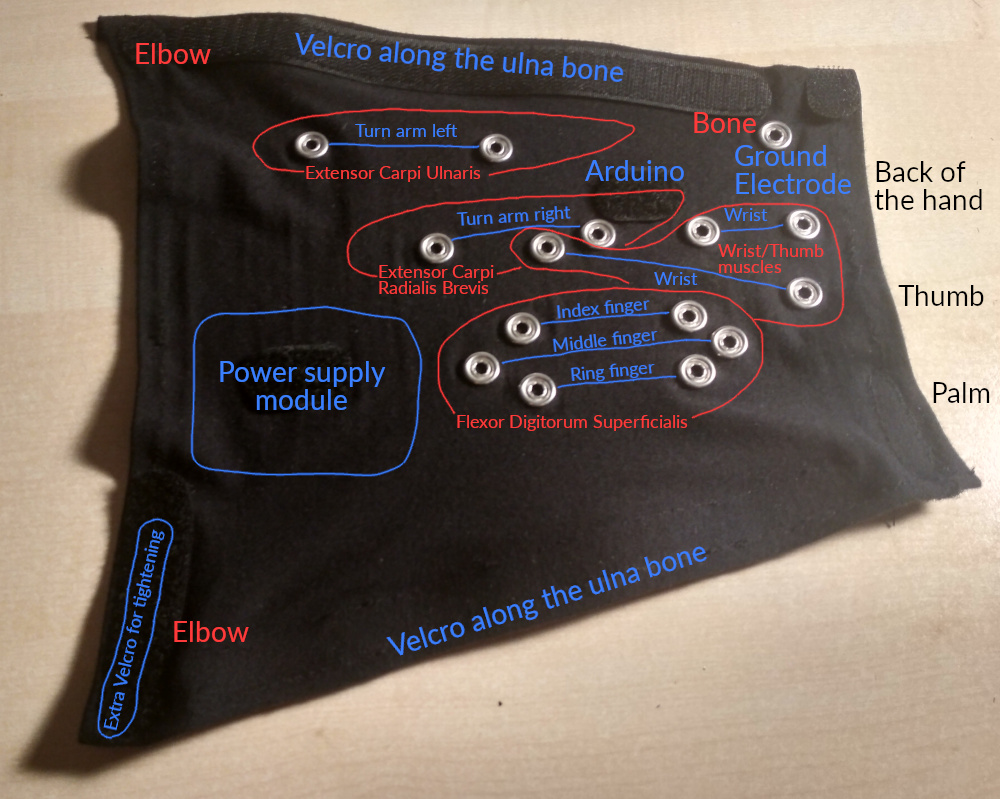

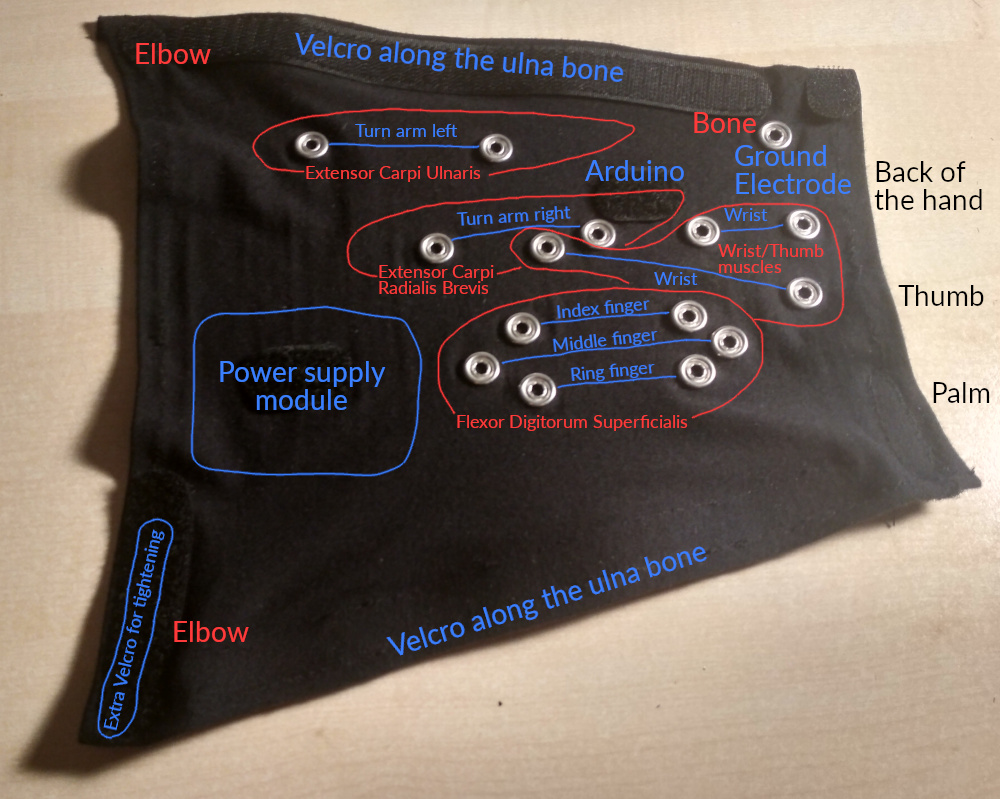

Electrode Placement

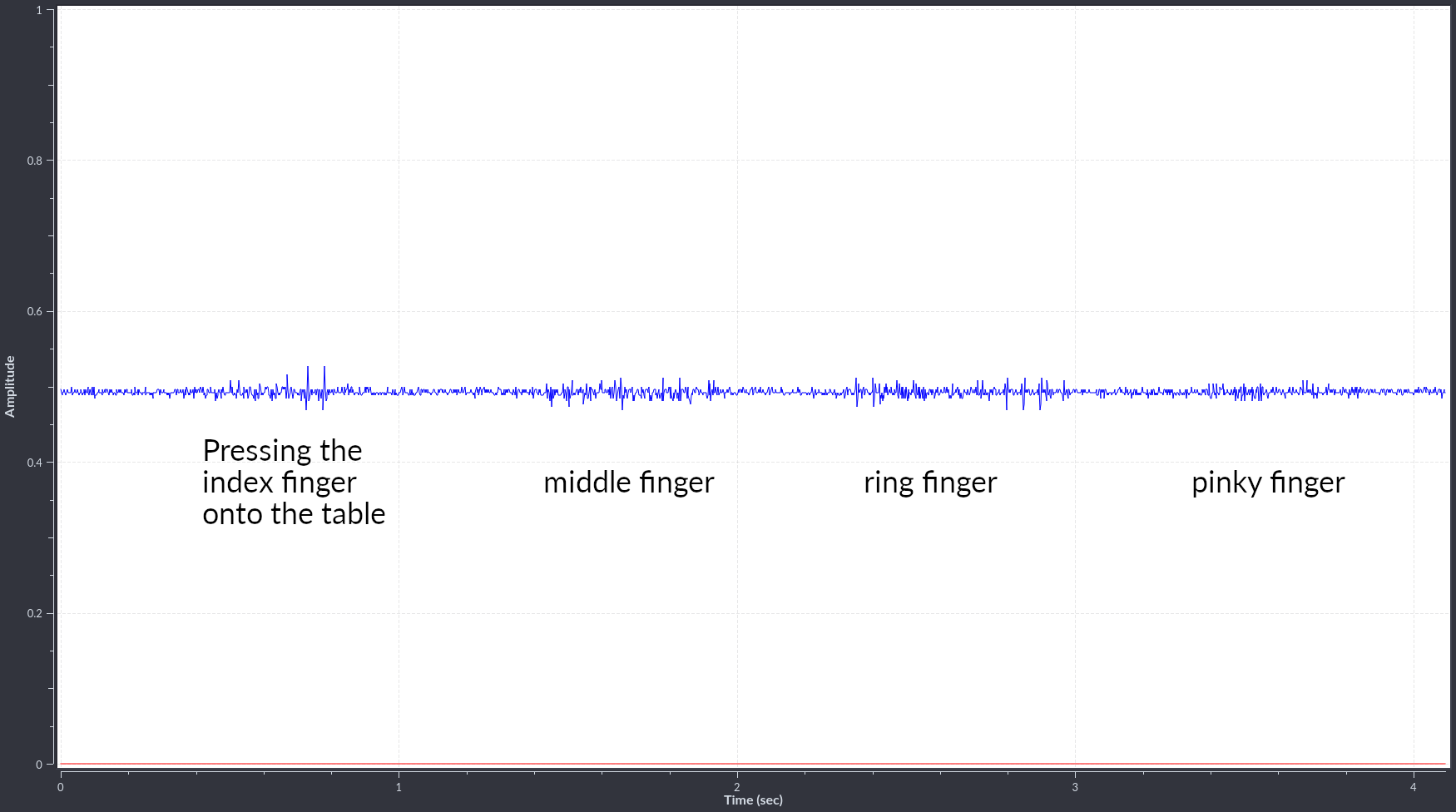

Then there was the question of where to put the electrodes. Using an

improvised muscle map along with two flexible electrodes on individual straps,

I could find spots whose electrical activity correlated with turning the arm,

twisting the wrist, or pressing individual fingers onto the table:

Flexor Digitorum

Superficialis

was particularly interesting; I found 3 areas over that muscle which map to the

index, middle and ring finger each. For turning the arm and wrist, the muscles

with "Carpi" in their name (e.g. Extensor carpi

ulnaris) worked

pretty good.) A huge disappointment was Extensor

Digitorum,

which is supposed to be active when fingers move up, but I could not find such

correlation. Then again, I use snap buttons for electrodes, so I'm not that

surprised.

The final layout of the electrodes:

This piece is fully separable from the electronics and therefore machine

washable.

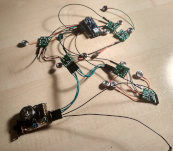

Here are additional pictures of the inner side, the separated electronics, as

well as everything combined. This nicely shows the tree topology of the green

signal processing modules that pass through the power supply among each other

to reduce the volume of wiring.

I could have had 8 electrode pairs, but only added electrodes for 7. On these

pictures, the electrode pair for the middle finger is also missing the

circuitry. That's mostly a testament to my laziness.

Actually I regret where I placed the Arduino, since there would be some great

spots for electrodes, but I noticed that too late. Will try to remove the

Velcro and maybe add an 8th electrode pair there.

The final cyb3rware:

While the signal was quite strong with the test straps, I found that the

amplitude of the signal went way down once I had everything attached to the

sleeve. Maybe there was some kind of interference from the Arduino or the

power supply being closer to my skin, or maybe the modal fabric messes with the

signal somehow. I hope I can compensate for this by increasing the signal

amplification multiplier, but I leave that for later.

This issue occurred with a single electrode pair already, but was aggravated

when attaching more of them. It might help if I add some flux capacitors to

the power supplies to prevent cross-interference.

Test Drive

I drove F-Zero with Prototype #2 before, but back then I

cheated a little bit. It only recognized 2 keys, left and right, and I

accelerated with the keyboard using my other hand.

This time I hoped I could do better, and trained the AI to recognize 3

different keys (left, right, accelerate) from my muscle signals. It even

kinda worked!

This was after recording ~2000 muscle signal samples over 1-2 minutes and

training a convolutional neural network for 25-50 epochs (<1 minute) on the

data using the PsyLink

UI.

I used 4 electrode pairs, all of which are on the dorsal side of the forearm.

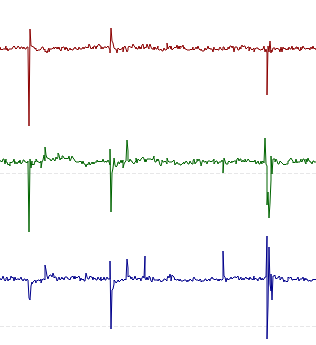

Analysis

In the racing game, I didn't make it to the finish line yet, and it does look

pretty clumsy, but I blame it on the software still having some obvious flaws.

It doesn't even account for packet loss or packet duplication when handling the

Bluetooth packets yet. Hope it will go better once I fixed them. Also, the

test drive was with only 4 electrode pairs.

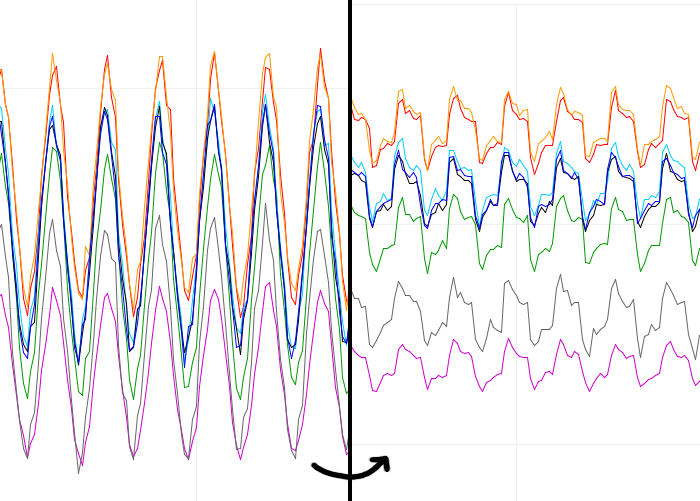

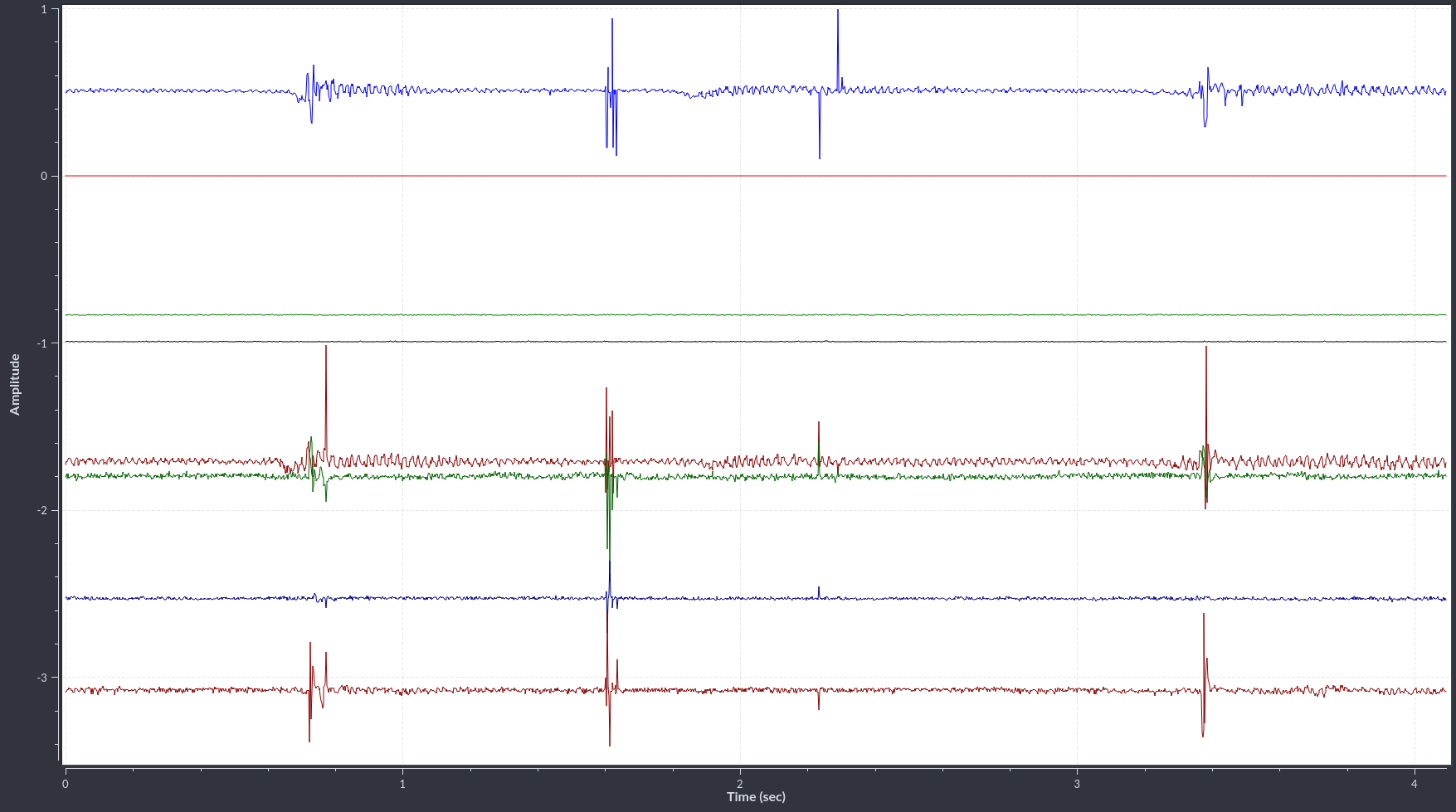

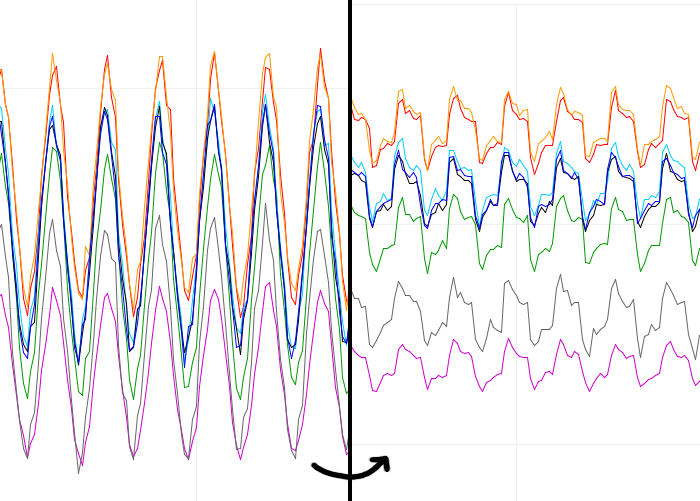

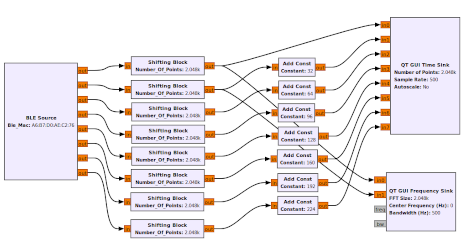

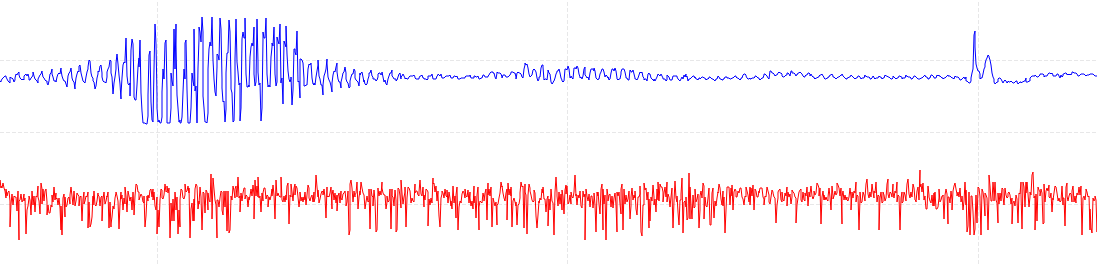

The raw values as visualized with the GNURadio

flowgraph

while randomly moving my forearm/wrist/hand show that the correlations between

the signals are low enough to be theoretically useful:

If you enlarge this image, you'll see that especially the black line is

considerably different, which I suppose is because it's the only electrode pair

that spans across several muscles. And that makes me wonder: Am I doing too

much pre-processing in hardware before I feed the data into the AI? Sure, the

differential amplification of this new prototype enhances small signals that

the previous prototypes might have not detected, but a lot of information is

lost too, like the voltage differences between electrodes from different

electrode pairs.

Maybe I can compensate for this by simply adding some more electrode pairs that

span muscles. I'm also thinking of switching to a design with 32-64 randomly

placed electrodes -> buffer

amplifiers

-> multiplexers

-> analog to digital converters of the Arduino. That way, the neural network

can decide for itself which voltage differences it wants to look at.

New PCB layout

While soldering the PCB, I found some flaws and made these changes to the

previous PCB:

- Added silkscreen labels to the connectors and components. I was sure I

wouldn't mix up anything since there aren't many connectors, they're nicely

symmetrical, and I'm the designer after all. But nope. I still mixed them

up.

- Removed unnecessary vias.

(I was actually not sure whether the pin holes will really conduct between

the front and the back side of the board, so I added vias as a safety

measure.)

- The label now shows the new name "psylink" instead of "myocular"

- A friend also gave me the tip to increase the thickness of power supply wires

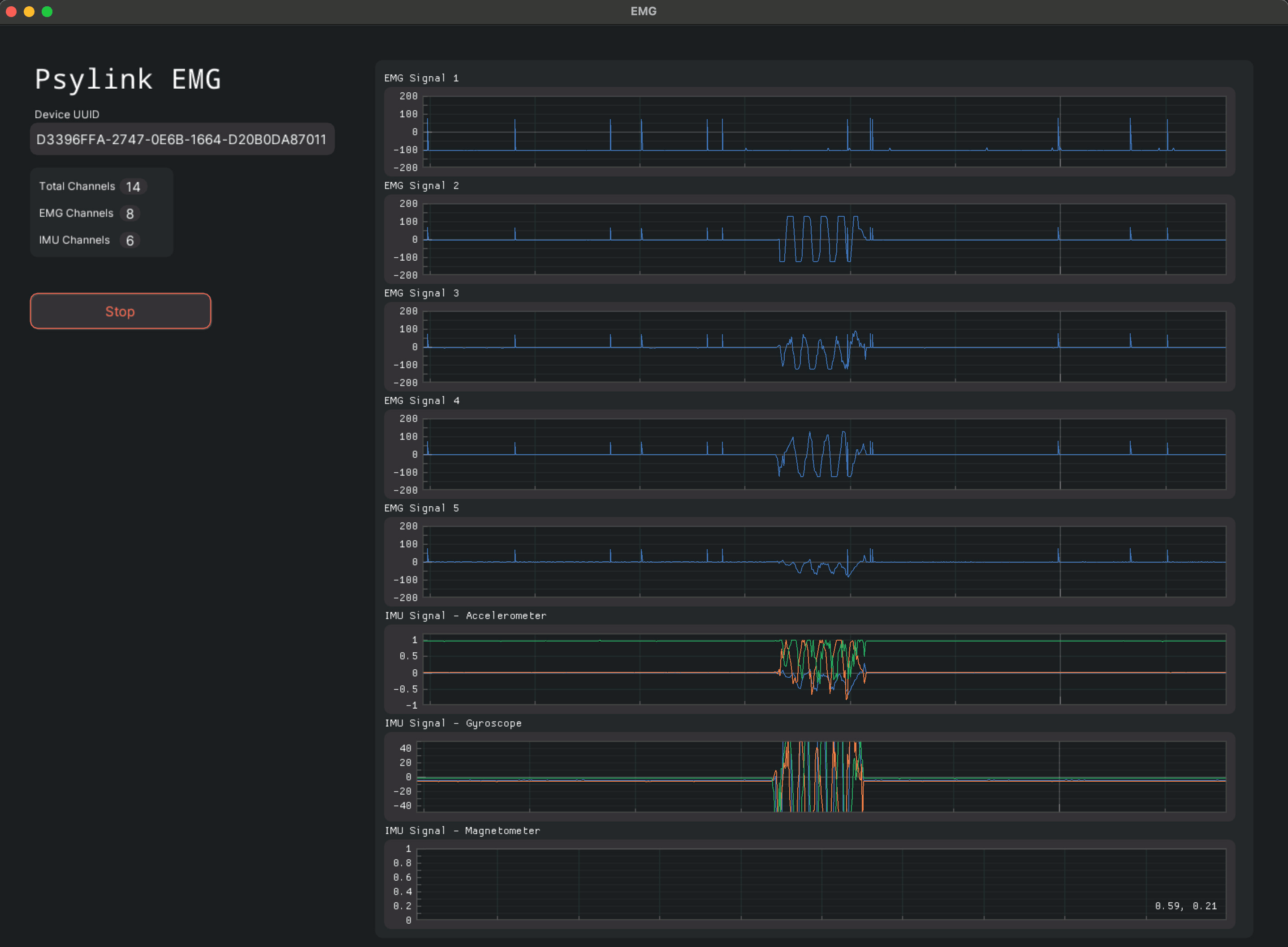

Gyroscope + Accelerometer

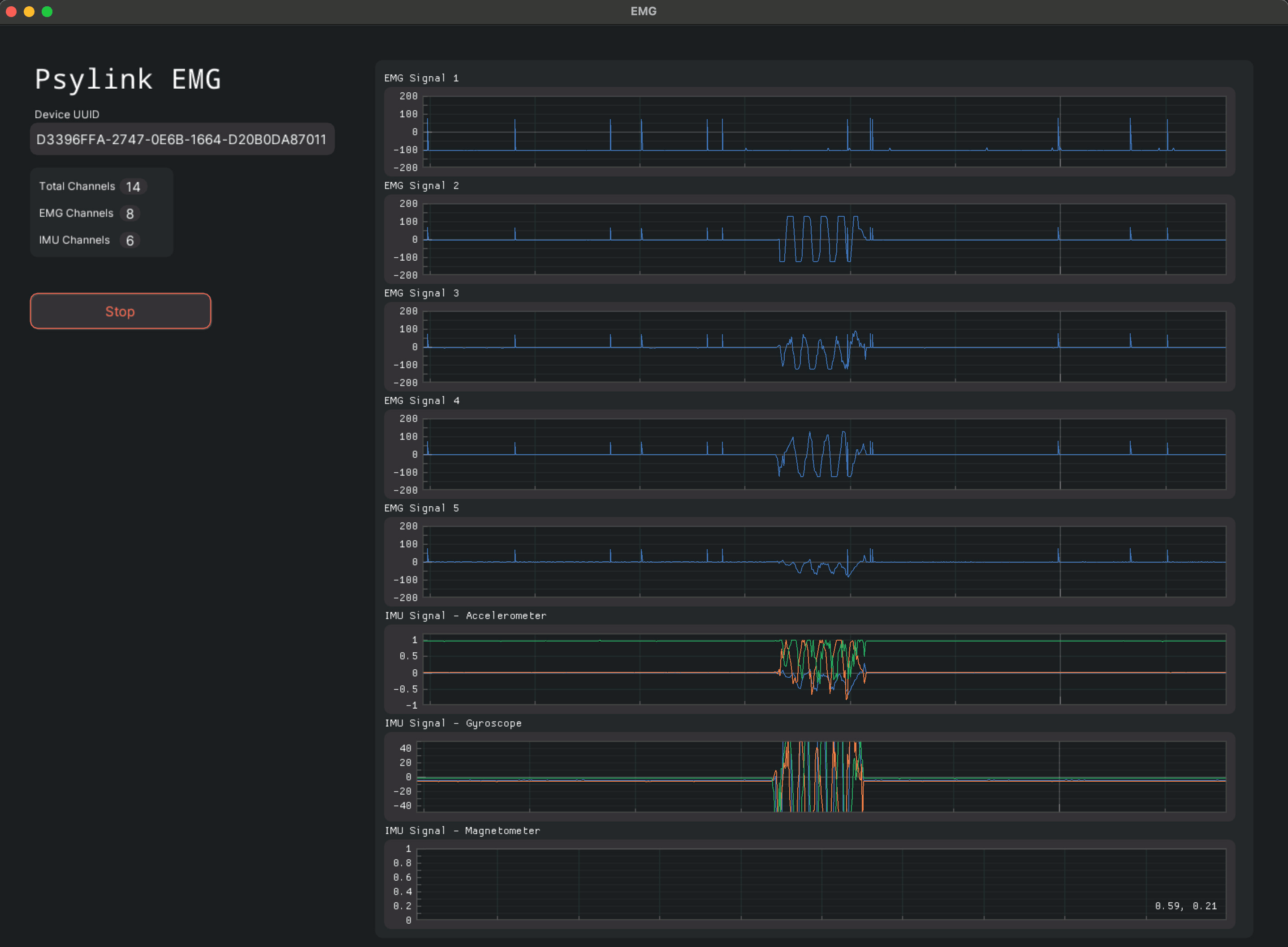

└2021-05-17, by Roman

I fixed up the PsyLink UI. It was so broken after the rewrite to Bluetooth Low

Energy, I'm once again stunned that I got ANY useful results before. But now it

receives the transmissions from the Arduino properly.

I also added 6 more signal channels: The x/y/z-axes from the Gyroscope and

from the Accelerometer that are built in to the Arduino Nano 33 BLE Sense.

All put together finally allowed me to singlehandedly drive through the finish

line of my favorite racing game F-Zero! \o/

- For training the AI, I recorded 60k samples over 2 minutes (500Hz)

- Trained for 5 epochs, which took 1 minute without GPU acceleration

- 4 training labels ("left", "right", "accelerate", "nothing")

- Final training and validation loss: 0.04, accuracy: 98%

- 6 layer neural network with 2 convolutional layers

- Music by Mitch Murder

Dedicated Website

└2021-05-29, by Roman

The PsyLink project now has it's own website: psylink.me,

and this is the place where I will continue the development log, as soon as I

finish the basic structure of the website.

Website is Ready

└2021-05-31, by Roman

The website is more fleshed out now, with a nice black/green design, neurons in

the background, and a logo that is based on the logo of the fictional

TriOptimum Corporation

from the System Shock game series.

Videos are now hosted on a PeerTube

Channel,

allowing me to upload higher quality videos in the future while keeping the

git repository of the website

small.

I also catalogued individual components (circuit schematics,

circuit boards, textiles, software) that

resulted from this project so far, and documented how they all fit together in

the prototype overview. Each component has an individual ID

now, that I can easily write, print or sew on the hardware so I don't mix

everything up. For example, prototype 4 has the ID "p4" and can be reached

directly via https://psylink.me/p4, while the signal processing board of

p4 has the ID "b1" and can be reached via https://psylink.me/b1.

Here's a screenshot, for a future time when the design has changed:

Back to the Roots

└2021-06-04, by Roman

While uploading the old videos to the new PeerTube

channel, I

viewed the first

video

once again, which shows a pretty good signal from just two pieces of aluminum

foil taped to the skin. And I wondered, why do I even bother with such a

complicated set-up like in Prototype 4? It was really annoying to

assemble, and the device is clunky and fragile.

Let's go back to the roots and build something more simple. Plenty of reasons:

- Having 8 small, distributed signal processing PCBs sounds nice at first, but

it creates more points of failure. With Prototype 4, I had multiple

instances where a connecting wire broke off, so this time I'd rather have

everything on one PCB.

- What happened to the idea of processing the signal as little as possible and

leaving the job to the neural network? Circuit 6 (whole device) amplifies certain

information but hides other, like the DC voltage offset between electrodes.

- The electrode map of Prototype 4 provides me with signals (like "arm

turns left/right") which are redundant since I added support for the

inertial measurement unit (IMU).

- The signal from the IMU is actually way more reliable than what I'm

getting from the electrodes, so why not ditch them completely? Well,

there are some parts of the arm that move separately from the Arduino,

mainly the fingers. So let's focus on these.

- My main issue with the early prototypes was the poor signal-to-noise ratio,

but that was mainly due to the power line. This should be gone with a

battery-powered device.

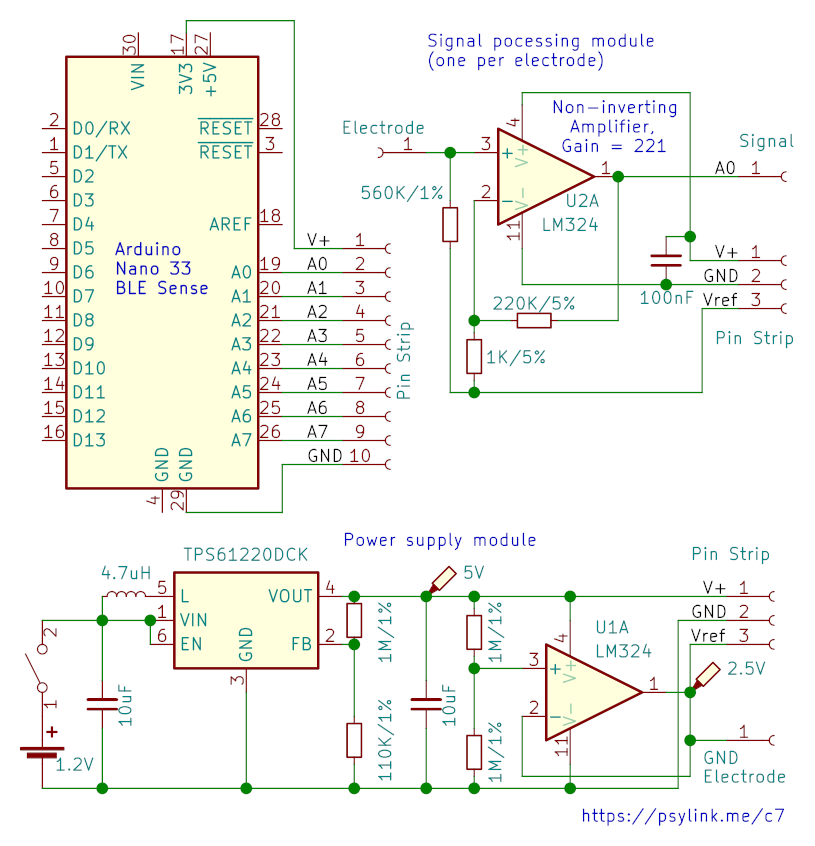

Circuit 7

The Circuit 7 (whole device) shows a simplification of the signal processing module to

a simple non-inverting amplifier per electrode with a gain of 221x. There's

also a 560KΩ bias resistor towards Vref so the voltage we measure isn't too far

off the center. In Circuit 6 (whole device) I had used 1MΩ, but here it produced

mysterious oscillations, and going

down to 560KΩ mysteriously fixed it.

This circuit also features a rechargeable 1.2V AAA battery with a TPS61220

step-up converter boosting the voltage to 5V, because I don't hate nature, and

I burned through enough CR2032 coin cells. Coin cells also aren't exactly

optimized for currents of 20mA, and thus get drained too quickly.

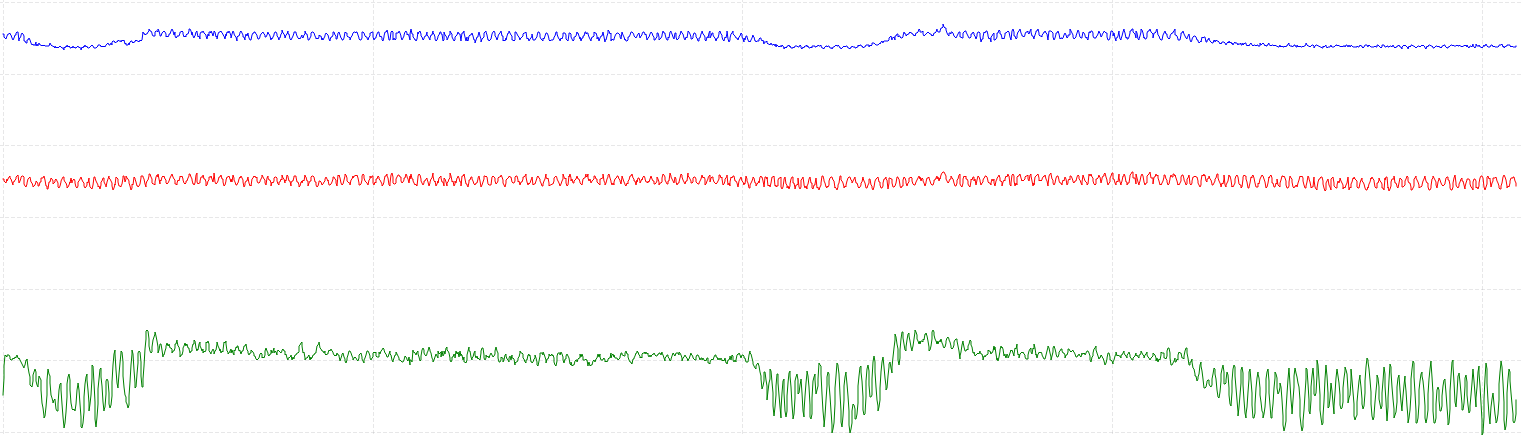

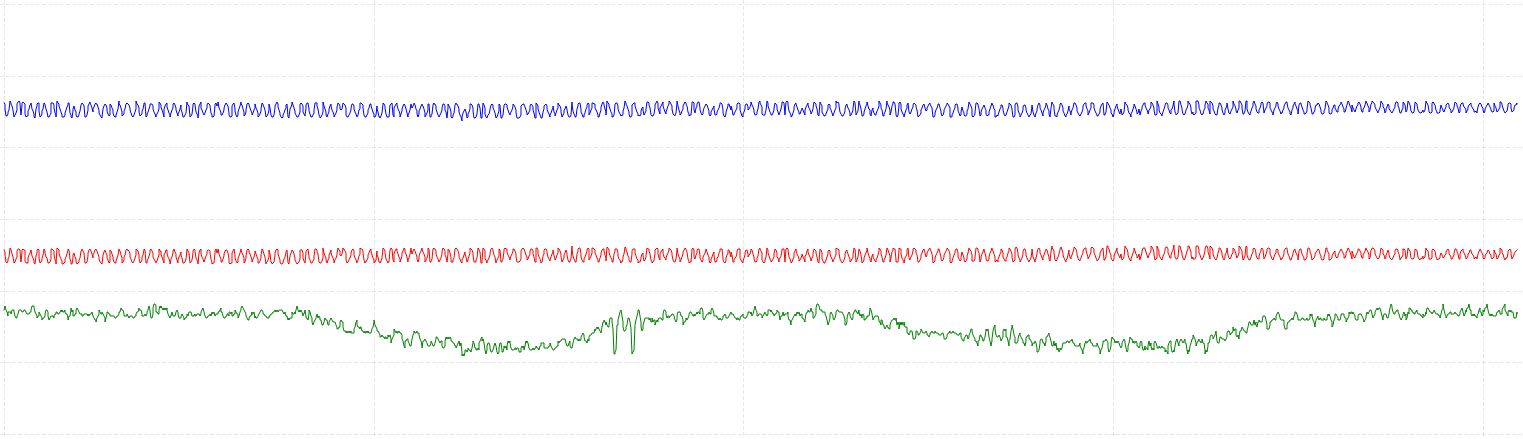

I measured a signal while pressing down a finger onto the table with two

electrodes along the Flexor Digitorum Superficialis. Blue is electrode 1,

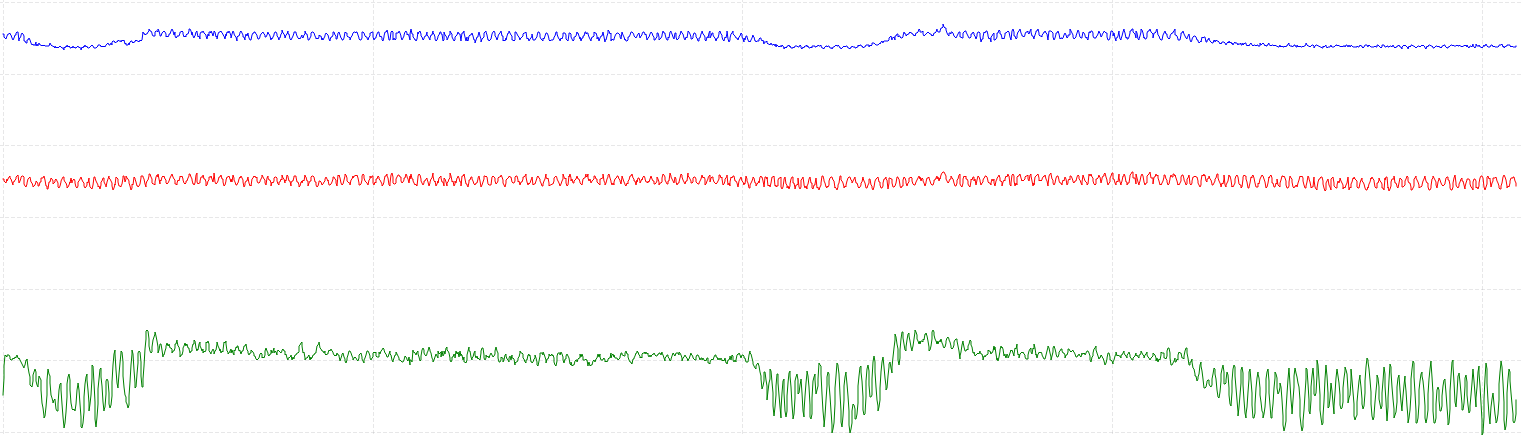

red is electrode 2, and green is an amplified difference:

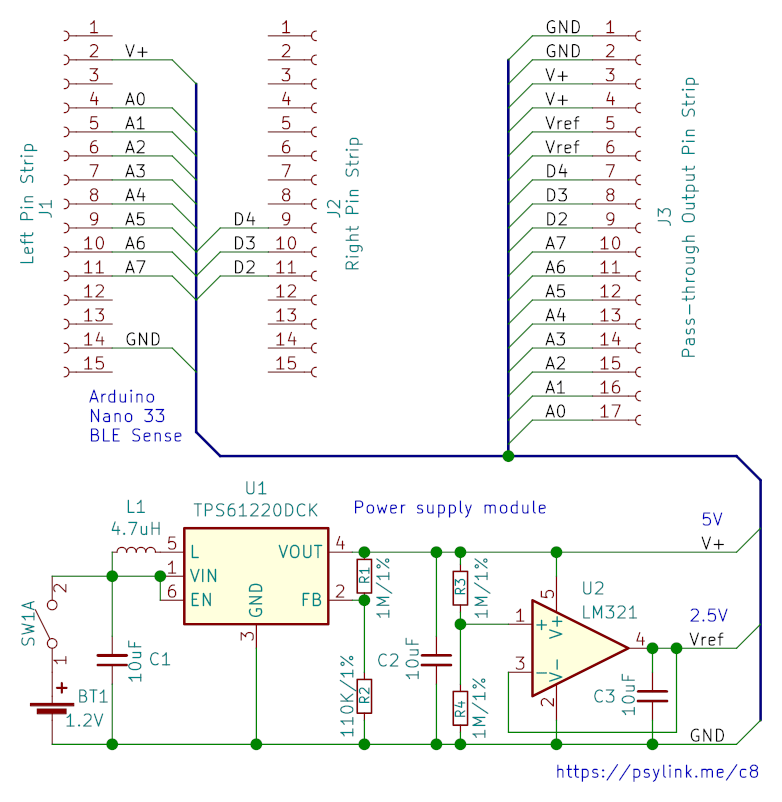

Circuit 8

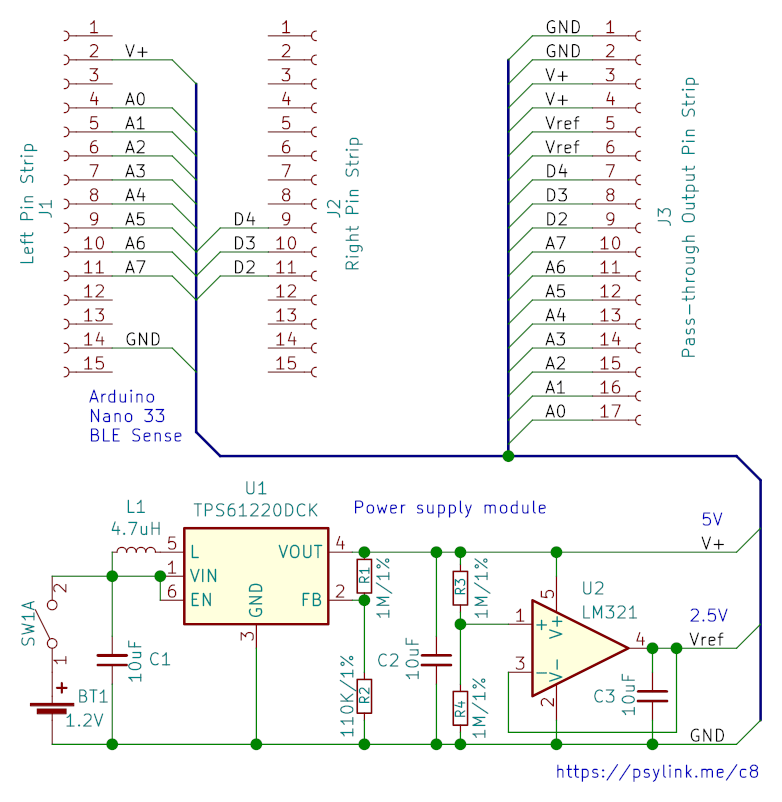

But let's cut even more out of this circuit. Here's one that is designed to be

a shield to the Arduino Nano 33 BLE Sense, containing just the power supply,

and an array of pass-through pins:

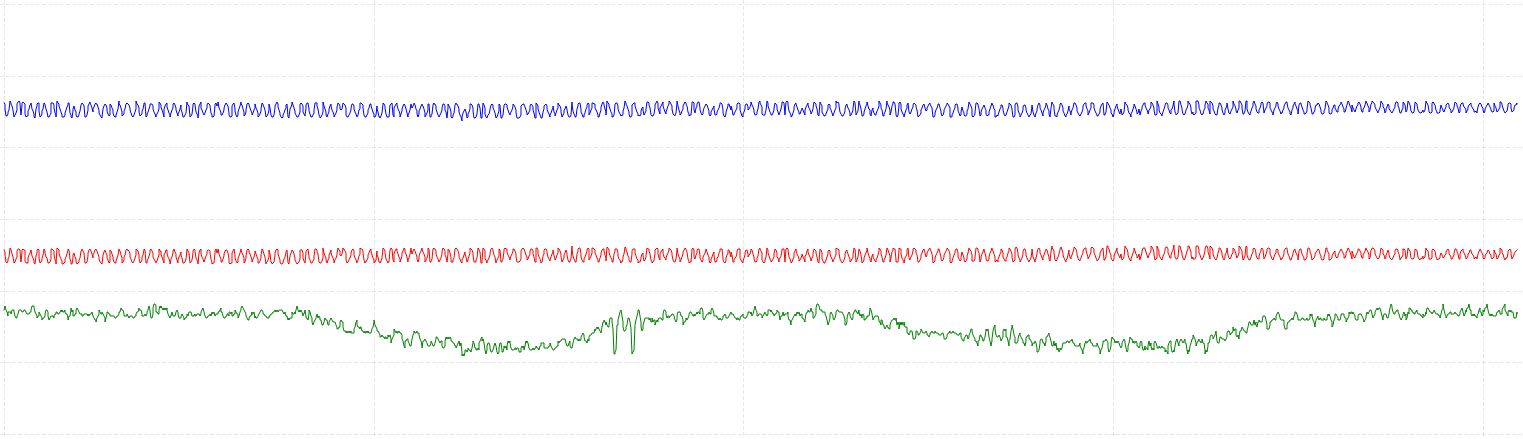

The signal that I'm getting is weaker, but certainly usable: (again, I measured

a signal while pressing down a finger onto the table with two electrodes along

the Flexor Digitorum Superficialis. Blue is electrode 1, red is electrode

2, and green is an amplified difference)

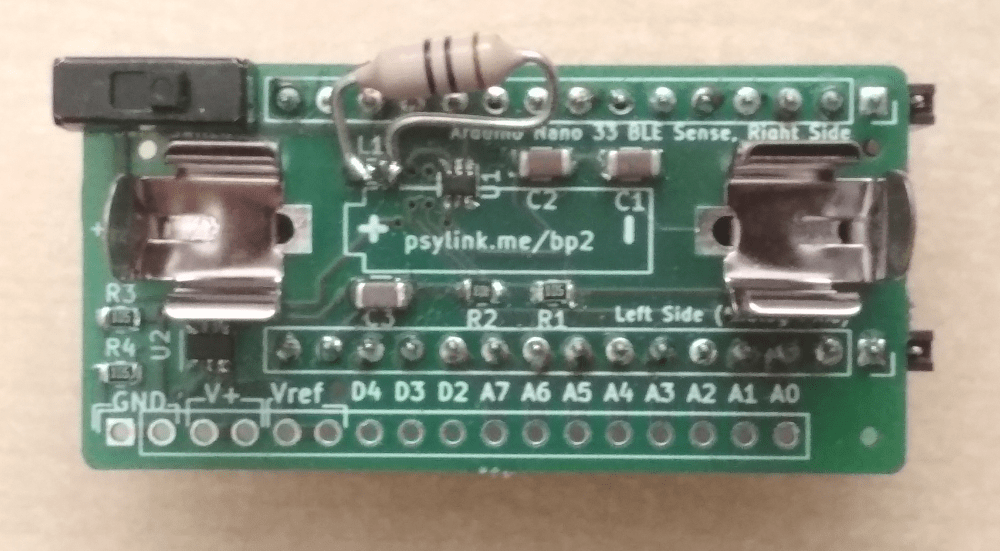

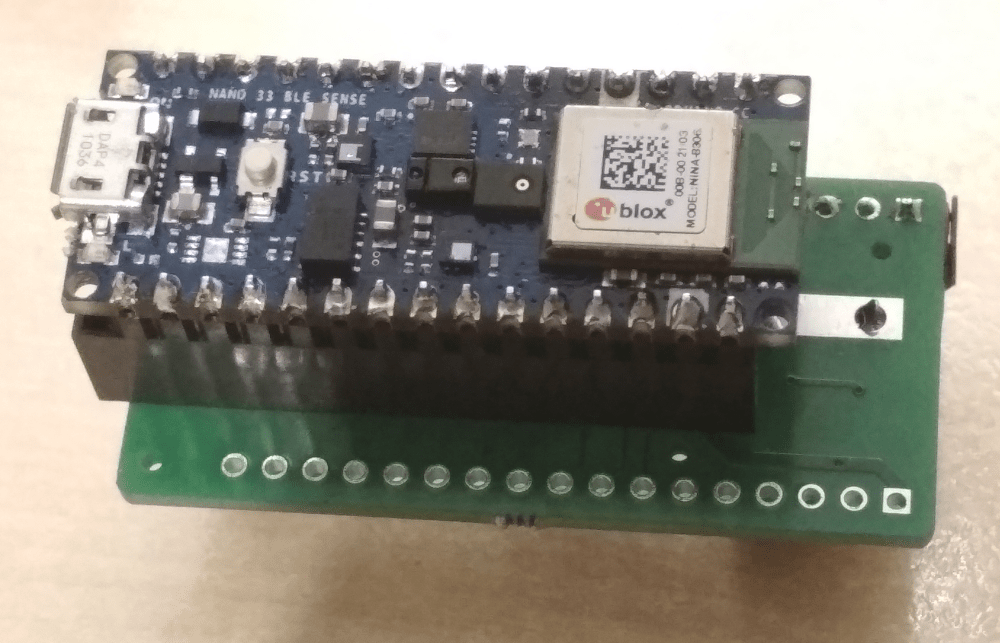

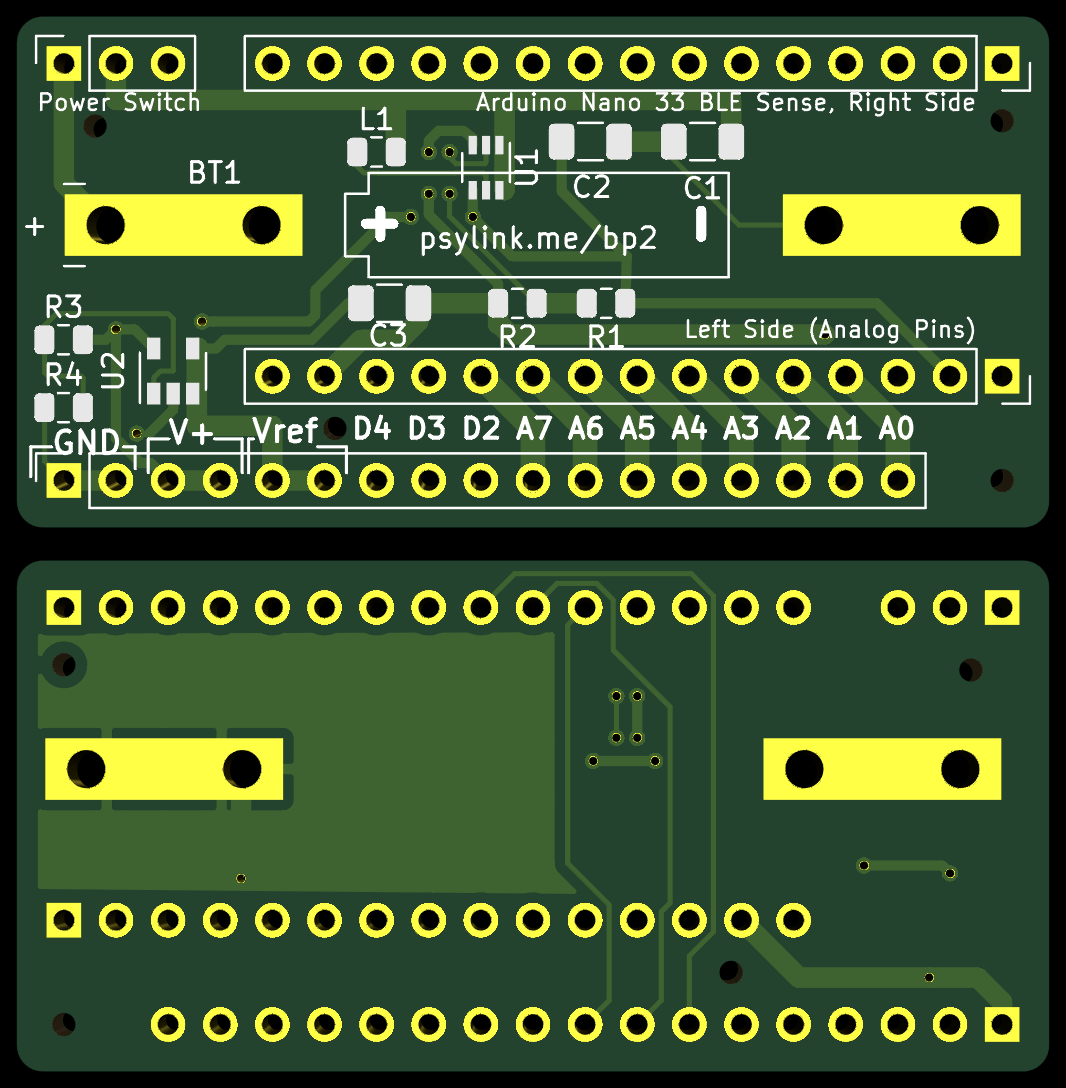

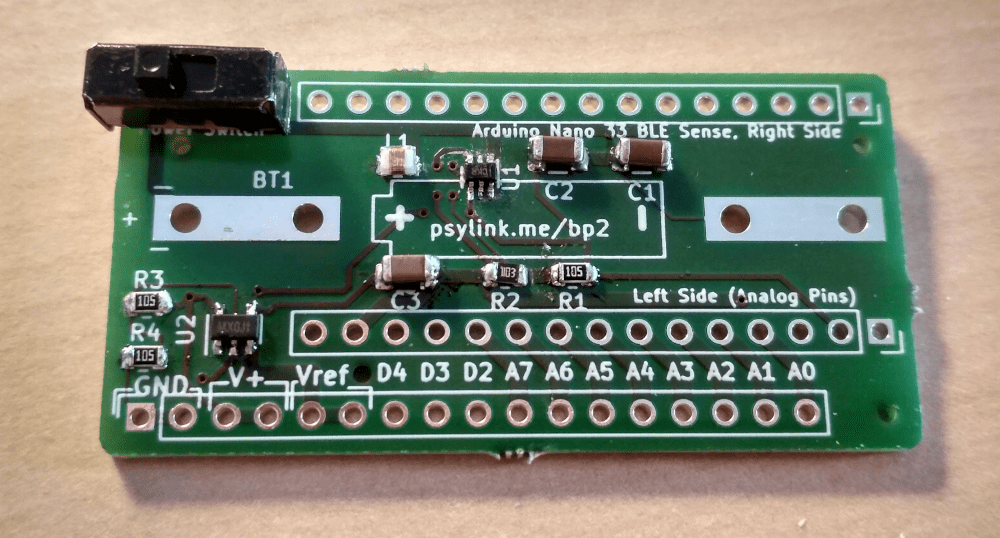

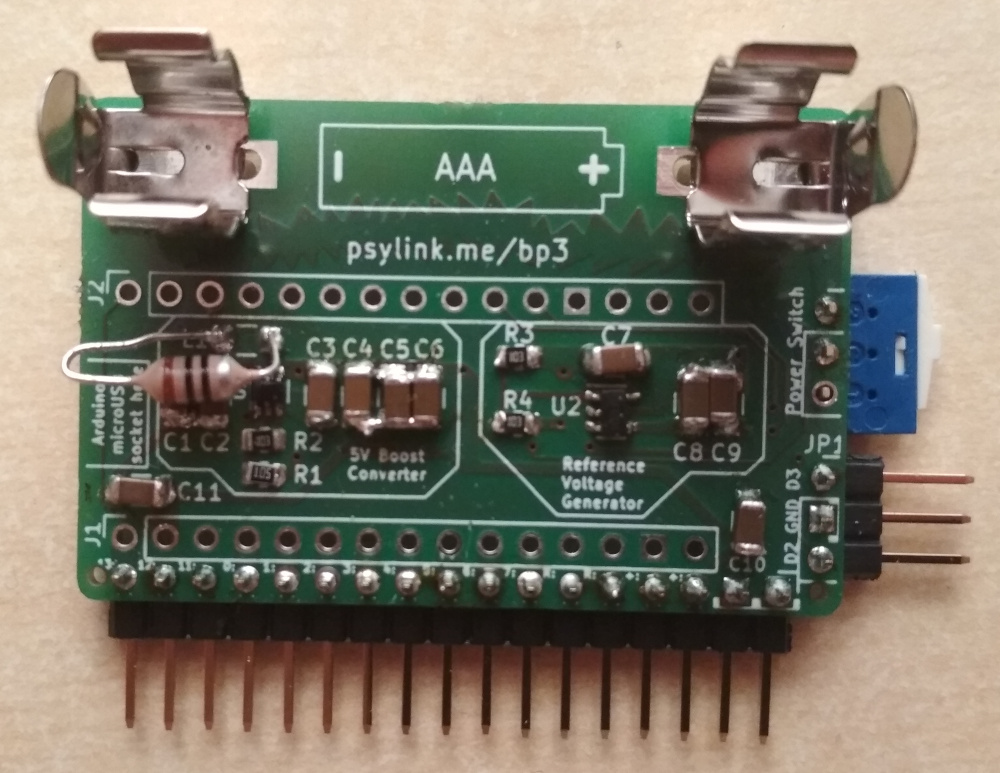

PCB

I also built a PCB that implements this power supply/pass-through shield, and I

figured, even if the device ends up not very useful, I'll still be able to use

this for experiments later on, thanks to the pass-through pins.

I just hope that the PCB/circuit will work at all. I still haven't figured out

how to simulate it, and I don't really know the best practices for PCB design.

The PCB footprint for the AAA battery clips (Keystone 82) is my first

custom-made PCB footprint too. Hope it all works out.

Next Prototype

It will be a relatively small forearm band with 8 electrodes (+ 1 ground

electrode), which I plan to place around the Flexor Digitorum

Superficialis

for detecting what individual fingers are doing. The information from the

gyroscope + accelerometer should cover the rest.

Believe The Datasheet

└2021-06-10, by Roman

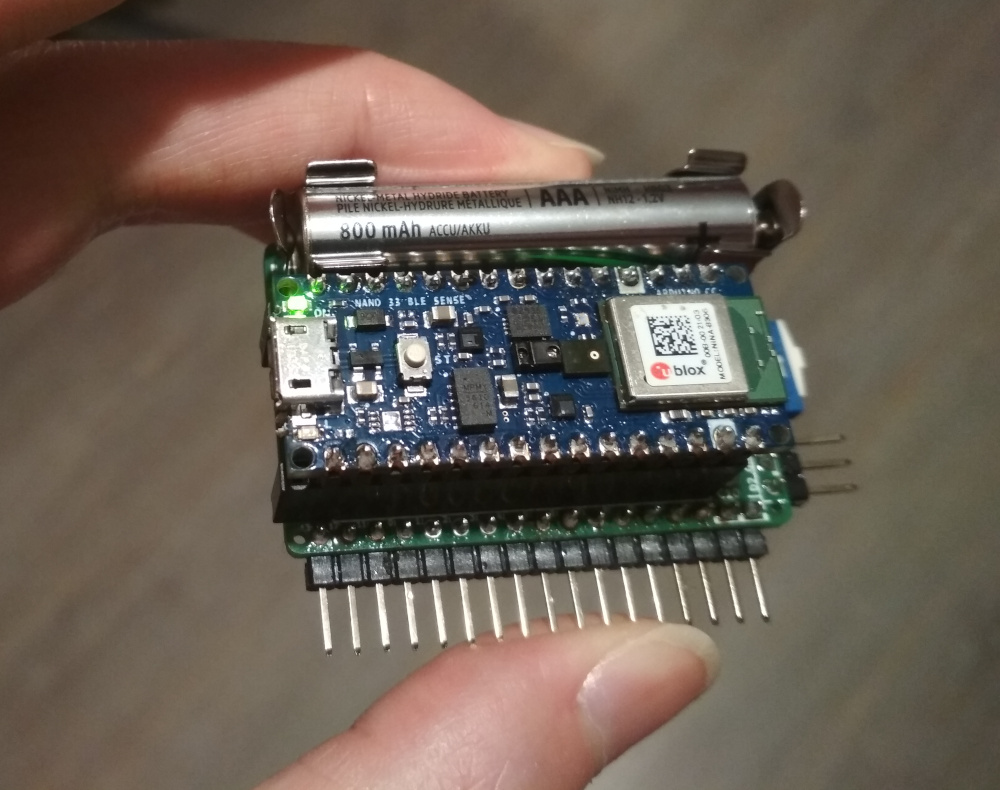

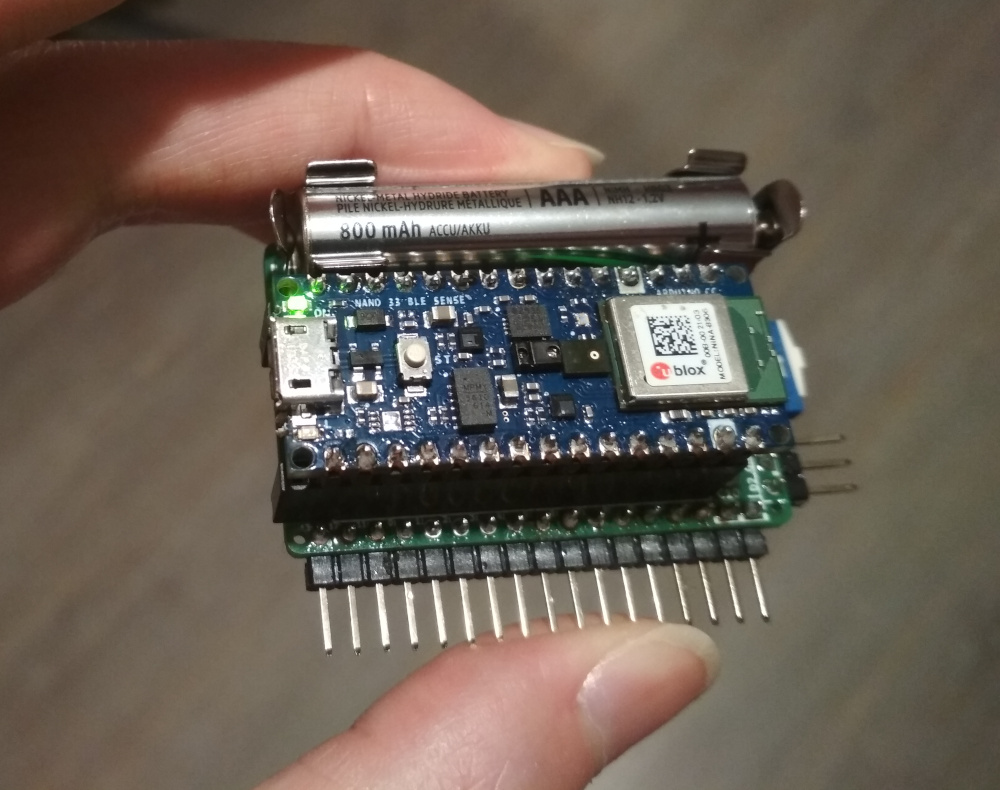

Today the order of Power Module 2 arrived!

And with relief I saw that the battery clips fit nicely onto the board, as does

the Arduino (with pin strips), and all the other components. Just that simple

thing already felt like an accomplishment at my level of expertise with

PCB design ;)

After some dreadful time trying to solder on the tiny 1x2mm-sized chip at U1 (I

need a microscope for this shit), I had the SMD parts assembled and the circuit

was ready for a test drive:

But something was weird. The output voltage was a meager 1.5V, not the

expected 5V, even though everything was connected properly. After hours of

debugging I flipped over the table and just soldered a fresh board, this time

without the Vref-generating OpAmp (U2+R3+R4+C3). But no luck, still just 1.5V.

This was lower than the minimal output voltage of the voltage booster, so the

chip didn't even finish it's start-up phase. How could that be, if there's not

even any load on the output voltage?

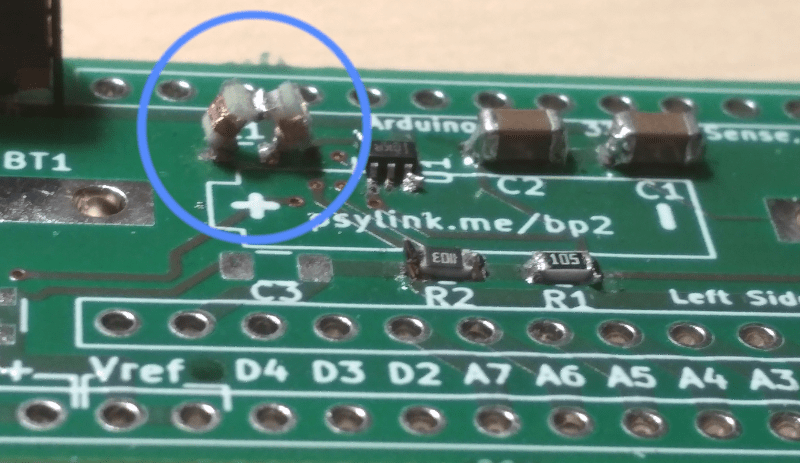

I desperately tried several different things. One was doubling the inductance

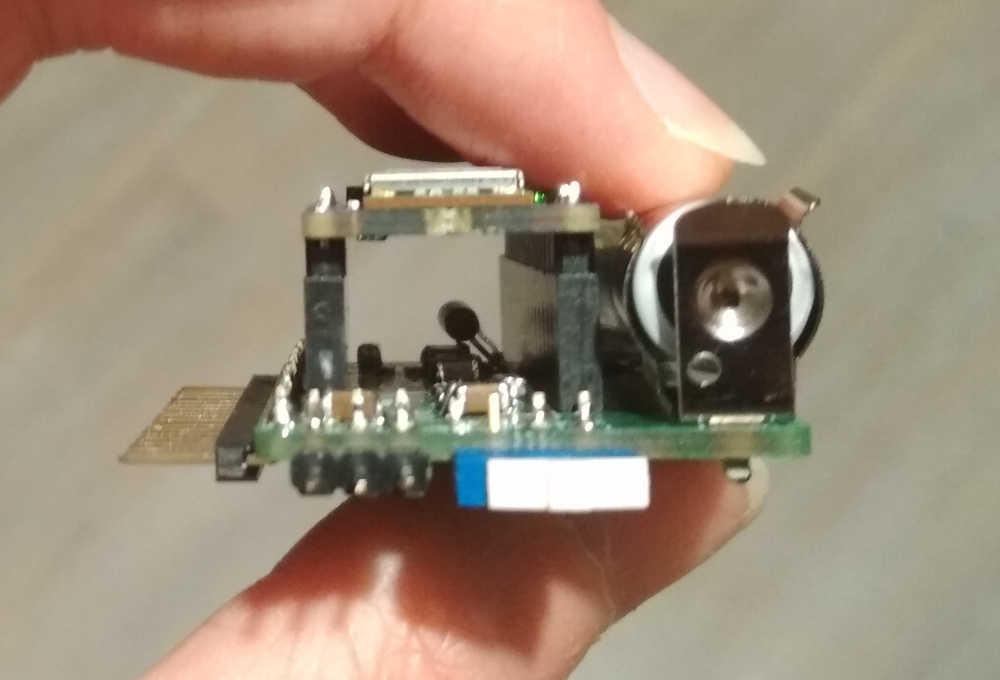

at L1 from 4.7µH to 9.4µH by using two SMD inductances in series:

Unfortunately I think I broke the coils while constructing this, since they

didn't let any current go through. But I found a regular, big inductance coil

with 10µH, manually held its pins down onto the SMD pads, and indeed, the

voltage jumped up to 5V!

So I soldered it... onto... the SMD pads.

(Probably you can reconstruct my entire room from all the reflections in this

image, along with a biometric picture of my face and at least 3 of my

fingerprints...)

But once I connected the OpAmp, the voltage went back down to 2.5V, and with

the Arduino connected, it went down further to 2.4V. Adding a second coil in

series for a total of 20µH didn't compensate for this, but made it even

worse, bringing it all the way down to 1.5V.

Well, clearly whatever is wrong with this construction has something to do with

the inductance, and it's not purely the amount of inductance... Which brings

us to the title of this post:

The mistake (probably)

Of course the data sheet of the voltage booster CLEARLY STATED that the

inductance coil needs to be AS CLOSE AS PHYSICALLY POSSIBLE to the chip. The

capacitors C1 and C2 too, by the way. And I even read that. But I thought,

what could possibly go wrong if I move it ~1cm away to make some space for the

battery? Nothing, right? Well, awesome, I guess it's time for another

revision :)

At least the 2.4V were enough to power the Arduino, although it was visibly

struggling. I could establish a Bluetooth connection and collect some signals,

but the Bluetooth packets were coming in extremely slowly (though still faster

than mobile internet in 80% of Germany.)

Pictures

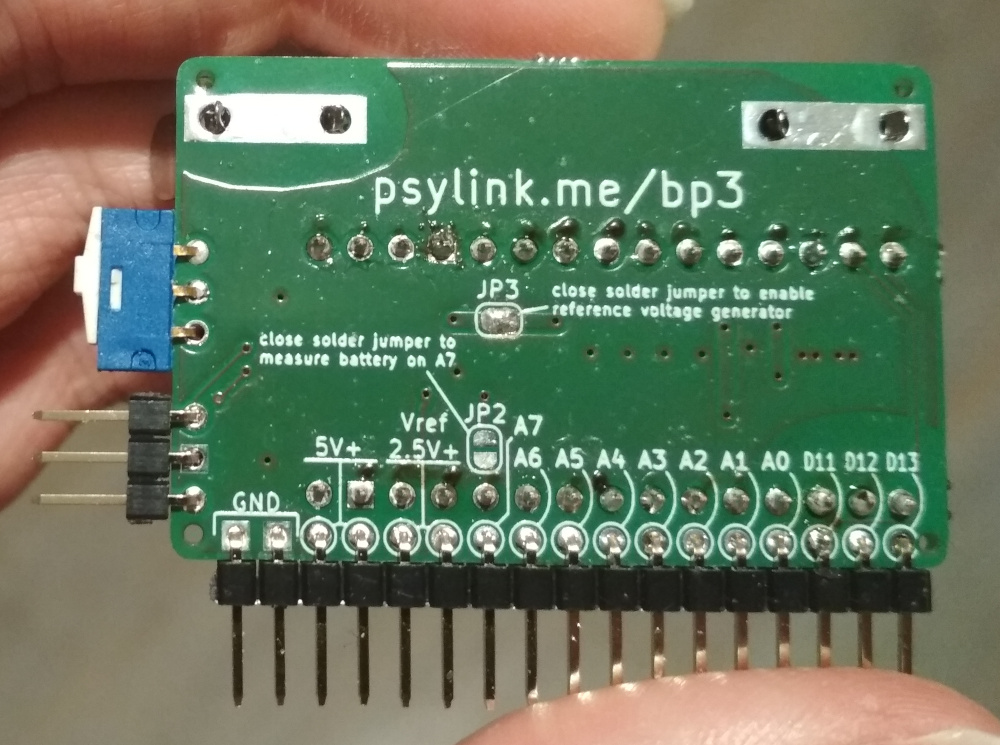

Front:

Somehow the oversized inductance coil adds a nice vibe to it.

Front, with battery:

Back, with attached Arduino:

This picture shows a pin strip socket that will be gone in the final version,

where the Arduino will be soldered onto the board, reducing the height from 3cm

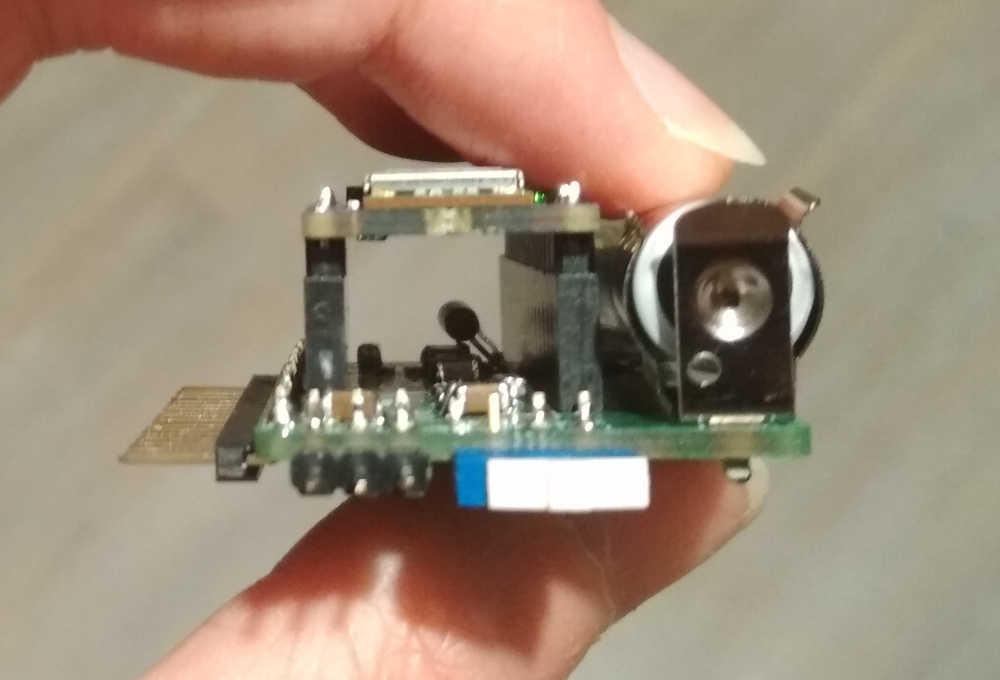

to 2cm.

Side, with Arduino and battery:

(Yes, the pin strip socket is too long by one pin ;))

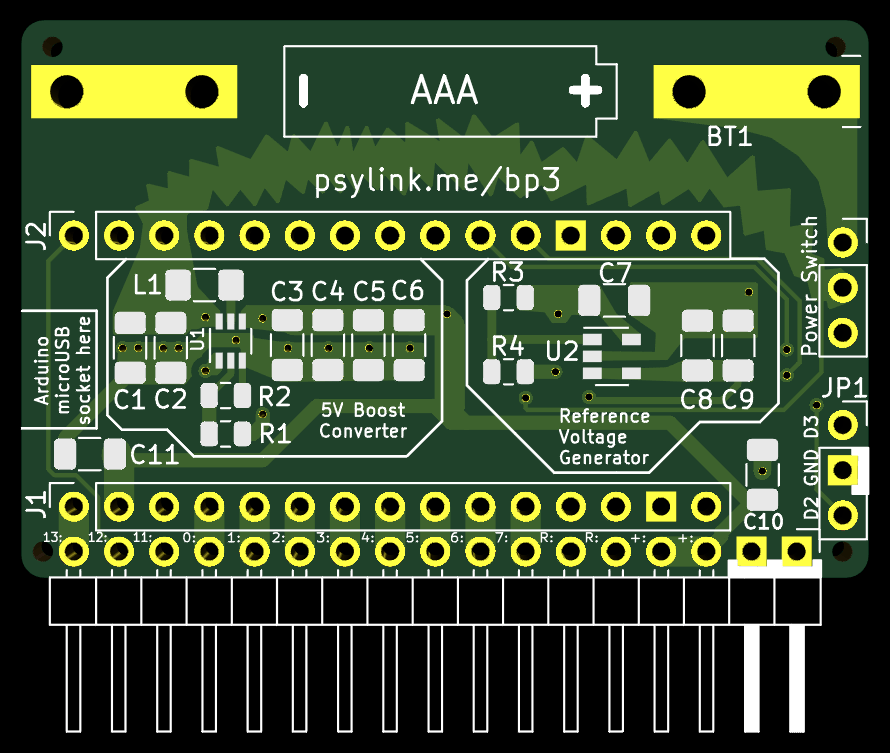

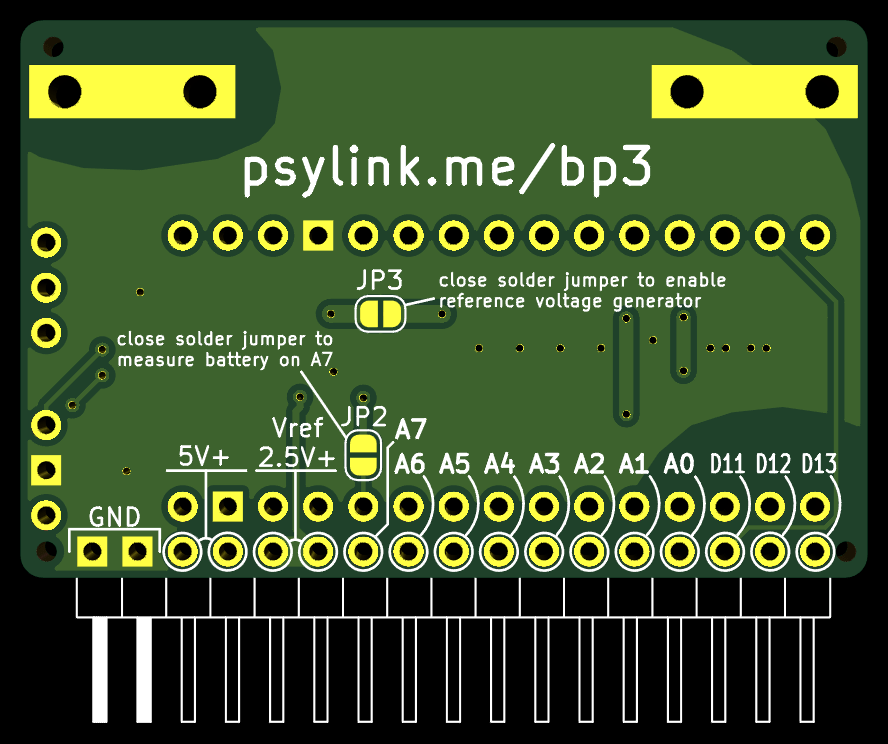

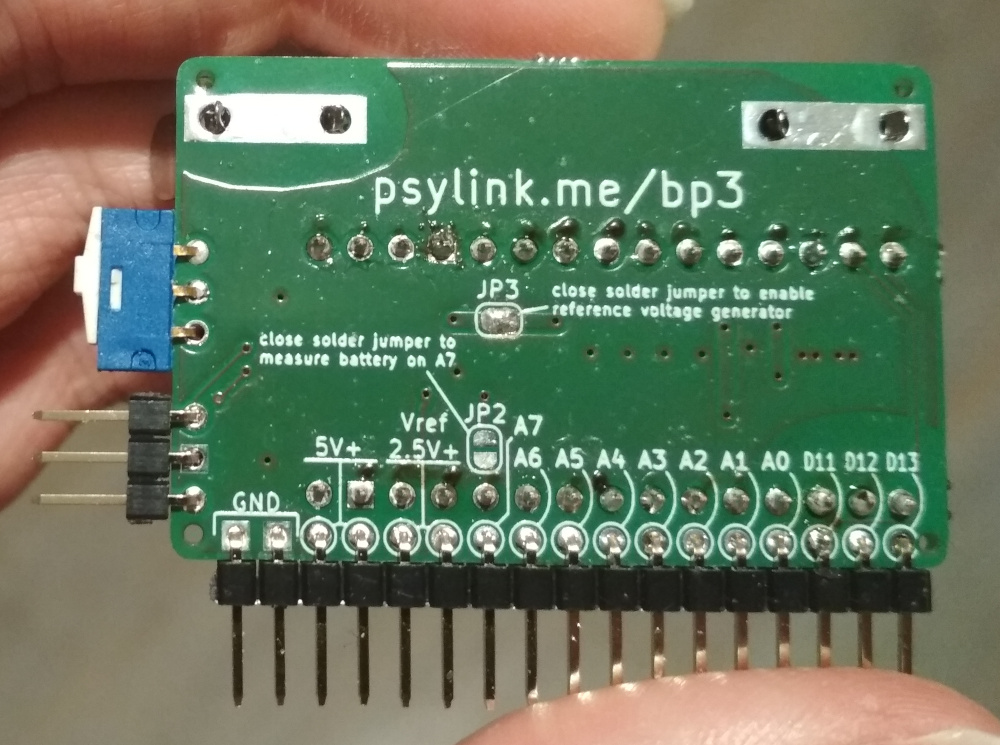

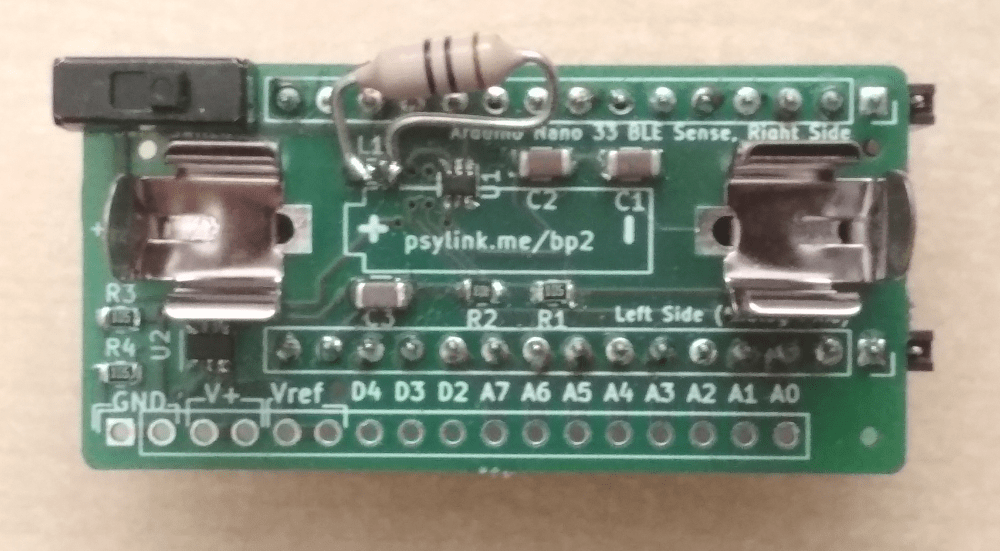

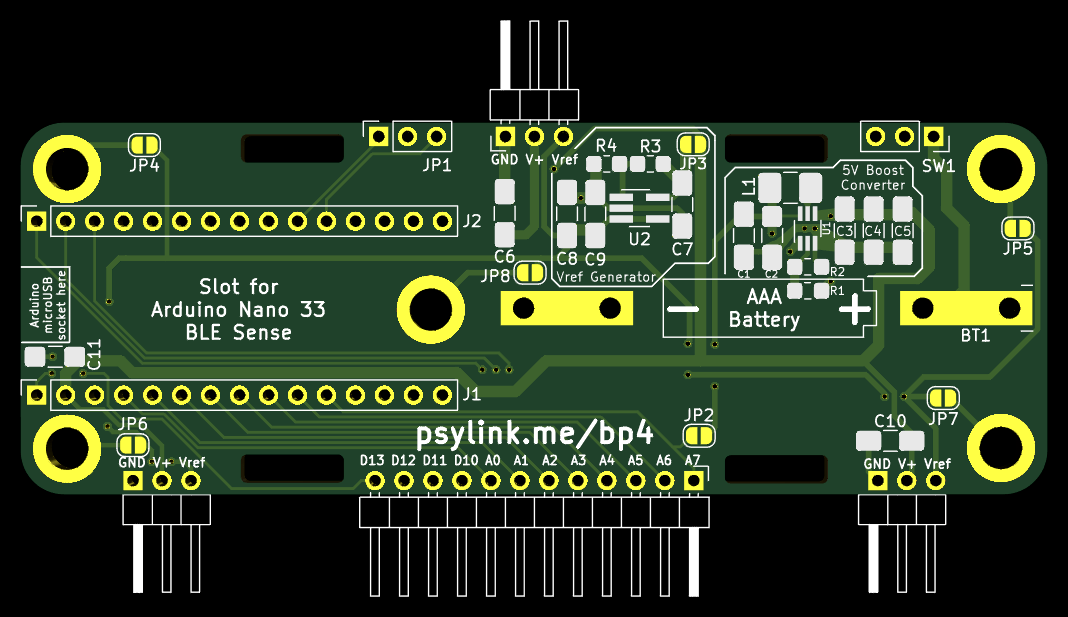

Power Module 3

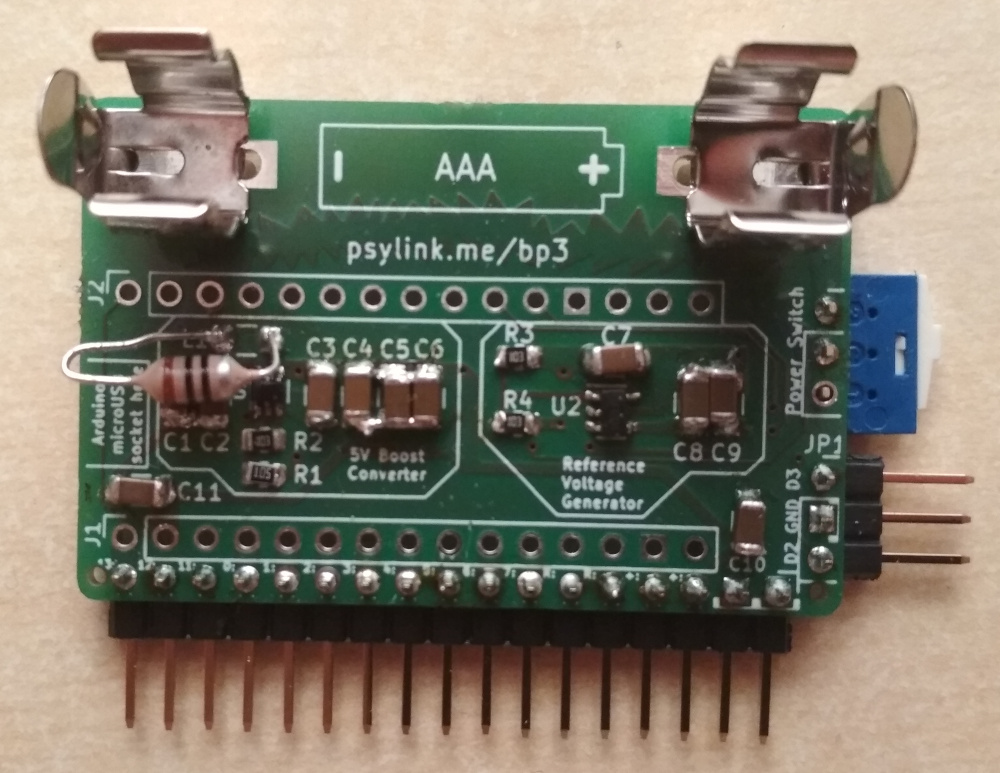

└2021-06-16, by Roman

Since Power Module 2 has the wrong PCB layout for the step-up converter, I

built Power Module 3 to fix this issue.

It was still a worthwhile learning experience to build Power Module 2,

resulting in the following changes:

- Instead of stacking the Arduino and the Battery on top of each other (one on

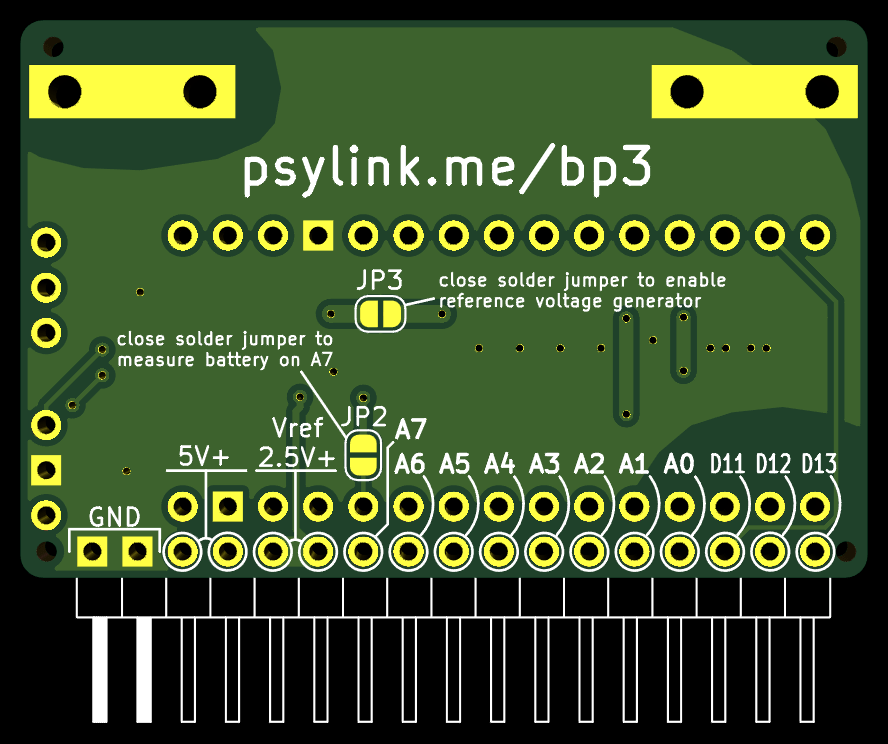

the front side of the board, one on the back), they're now side by side, to

make the board flatter and fit better on the forearm.

- Added more capacitors all over the place

- Added various jumpers:

- A solder jumper to enable/disable the reference voltage generator, in

case I come up with a setup where I won't actually need it

- A solder jumper to sacrifice one electrode and use its analog input pin

to measure the battery charge instead.

- Three configuration pins, connectable via jumpers, to change software

settings on the fly and toggle between up to 4 different modes. Or you

can use them to plug in an extra module.

- Hopefully fixed the layout for the step-up converter

Here's the circuit:

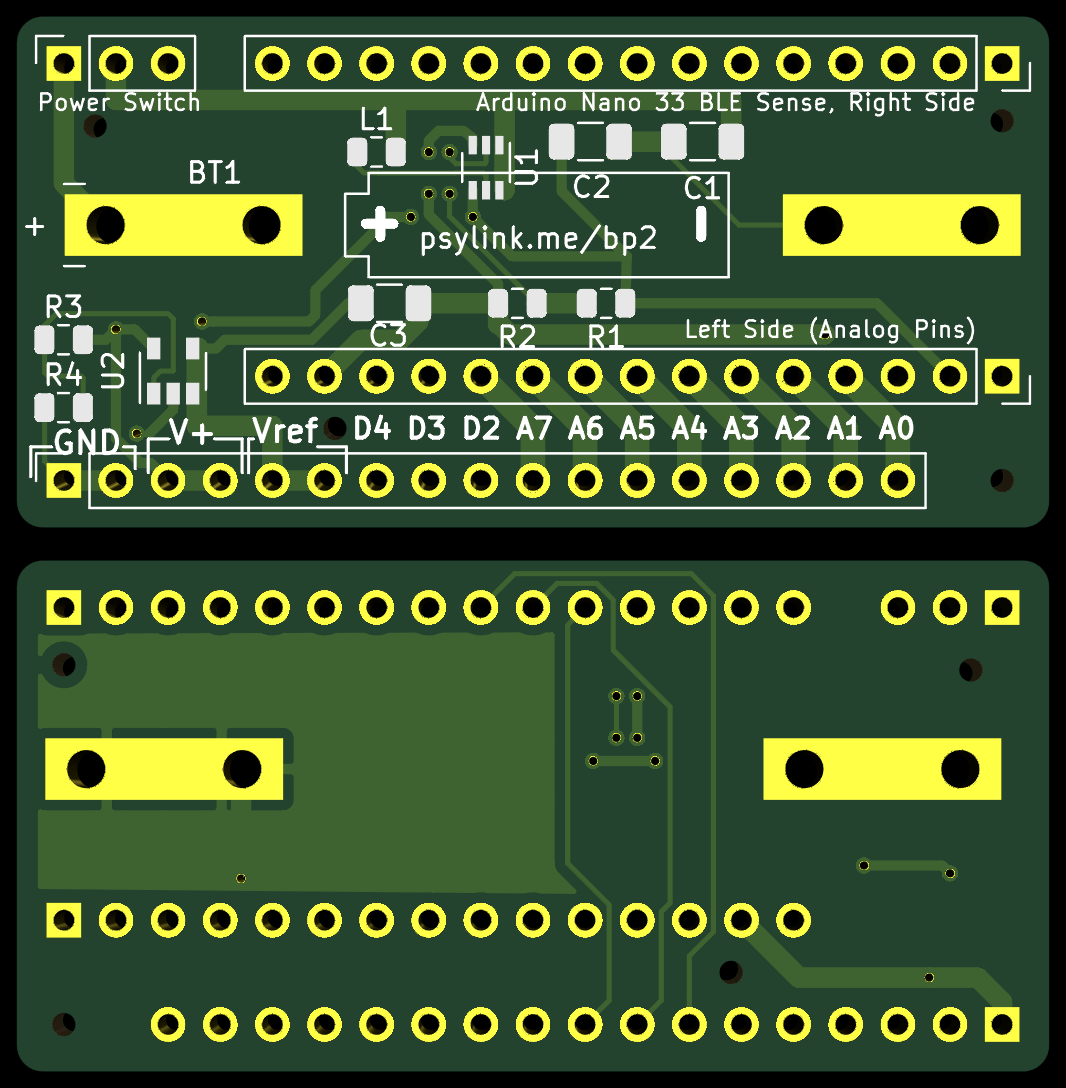

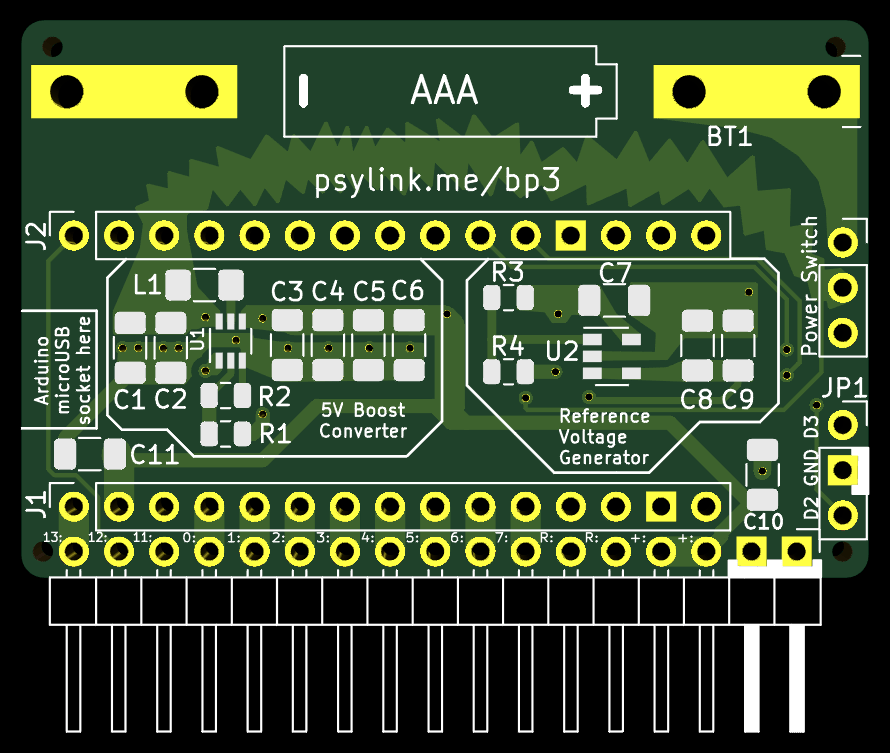

And the new PCB:

If you're wondering why the sparky, fancy looking power line goes all the way

from the power switch on the right through digital pin D10 and into L1 on the

left side... Indeed that looks pretty awkward, but L1 is the noisiest

component, and I wanted to keep it as far as possible from the analog pins at

the bottom, without sacrificing the effectiveness of the boost converter

layout. Given the size & time constraints, I didn't find a better solution.

What time constraints, you ask? Well, actually I made a different PCB layout

first. Polished every detail, and when it was perfect (according to my crude

appraisal), I ordered it. Was already excited about the delivery, started

putting the board on the website, and so on. But at some point I noticed that

something was wrong... The Arduino pins were inverted. Theoretically,

everything would still work, but the Arduino would have to be plugged in from

the back side, which is something I wanted to avoid to keep the board laying

nice and flat on the forearm...

Thankfully the manufacturing process hasn't started yet, and I could update the

board for free. So I started redesigning half of the board and finished just

in time for the production to start :D

Let's hope it works this time.

Running on AAA battery

└2021-06-21, by Roman

Wow, it feels like ages since I started working on making PsyLink run on a

rechargeable AAA battery. It sounds so simple and straight-forward, but it

wasn't :). This ate 2.5 weeks of my time, but finally I succeeded!

Coming from software engineering, the iteration time of hardware prototypes is

horribly slow. There was a lot of waiting for package deliveries, a lot of

time assembling, and a lot of wrestling with leaky

abstractions.

For example, it wasn't enough to just connect the 1.2V->5V boost converter like

on the circuit diagram, but I had to take special care of the distances between

the parts, and the widths of the copper tracks connecting them.

Another problem you never face in software engineering is that the package with

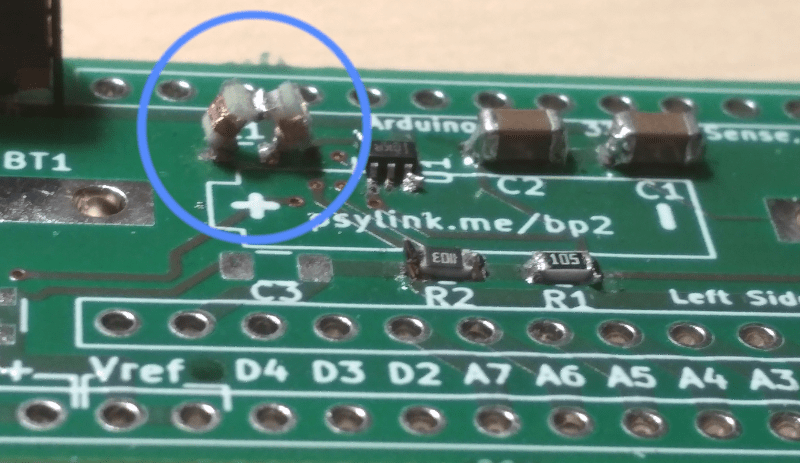

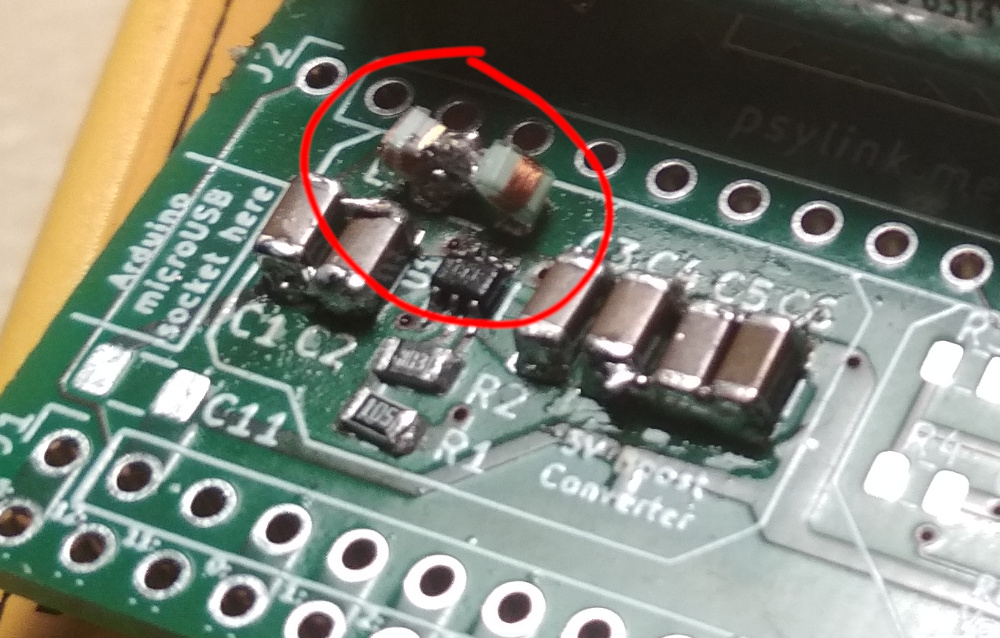

electronics parts was stolen, and when the new PCB of Power Module 3

arrived, I had to work with the few remaining (suboptimal) parts that I had.

What almost drove me insane was that I had only one fresh TPS61220 chip left.

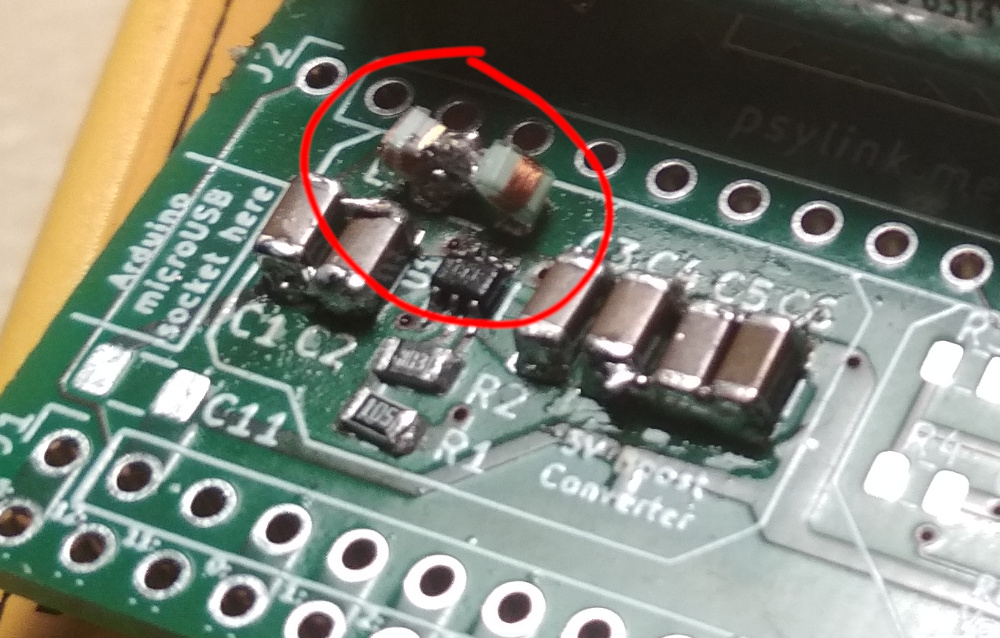

That's the 5V boost converter at position U1 (in the bottom of the red circle

on the photo below), which is so small that I don't really have the tools to

solder it on properly. I kept accidentally connecting the pins of the chip

with solder. I gave up and started asking around friends for whether they

could solder it on for me, when I remembered this soldering tip someone gave

me: If you don't have soldering flux (which I didn't have), just use

✨margarine✨ instead ;D. It sounds very wrong, but it actually made a huge

difference, and only thanks to the power of margarine I was able to keep the

solder exactly where I needed it to be. "If it's stupid and it works, it's not

stupid."

Then - for whatever reason - the voltage was going up to 1.5V instead of 5V,

just like with the previous PCB layout. I thought I fixed

that problem by optimizing the layout around the TPS61220

chip, but apparently that wasn't enough. I figured the

4.7µH inductance at L1 wasn't big enough, so I squeezed in a second coil:

(It looks like two tardigrades playing ball :) I wish I made a better picture

before I disassembled it again)

This alone didn't help, but when I manually held an additional 10µH

inductance in parallel to L1 for 1 second while the device was running, it

surprisingly kickstarted and reached 5V!... until I drained some current, which

made the voltage collapse back to 1.5V immediately. Curious behavior. :D

Then I tried soldering on the big 10µH coil directly onto the SMD pads,

and the voltage reached 5V and stayed at 5V =)

No idea why the big 10µH coil worked while the two smaller coils totaling

9.4µH didn't work... I doubt that the 0.6µH difference in total

inductance turned the tide, probably there's some factor I'm not aware of. I

actually had ordered a 10µH SMD inductance coil in anticipation of this,

but well, it got stolen... My only consolation is the face of the package

thieves when they open the package, they realize that it's just a couple of

tiny SMD parts, and they wonder WTF this shit is even good for.

P.S.: I found out that the reason why the coils didn't work was that they were

not rated for the >200mA that's passing through them. Once I got a 4.7µH

coil rated for 280mA, everything was fine.

More pictures:

The lack of parts forced me to adjust the resistance/inductance/capacitance

values of Circuit 9 (power):

Thankfully I had planned for way too many capacitors on the PCB, just for some

extra VROOOM, so the fact that I only had 10µF capacitors instead of the

planned 100µF didn't matter too much.

I also changed the 1MΩ resistors in the reference voltage generator to

110kΩ because I read that smaller resistances in a voltage divider make

the output voltage more stable, at the cost of more power use, but I think we

can sacrifice some power for signal accuracy. No idea whether it's actually

going to help though. I chose 110kΩ instead of the more common

100kΩ and 220kΩ because the boost converter already requires

a 110kΩ resistor, and that way this prototype requires fewer different

parts. But the exact values don't matter, as long as both resistances are

identical.

Tomorrow I'll start working on the electrodes and wristband. :)

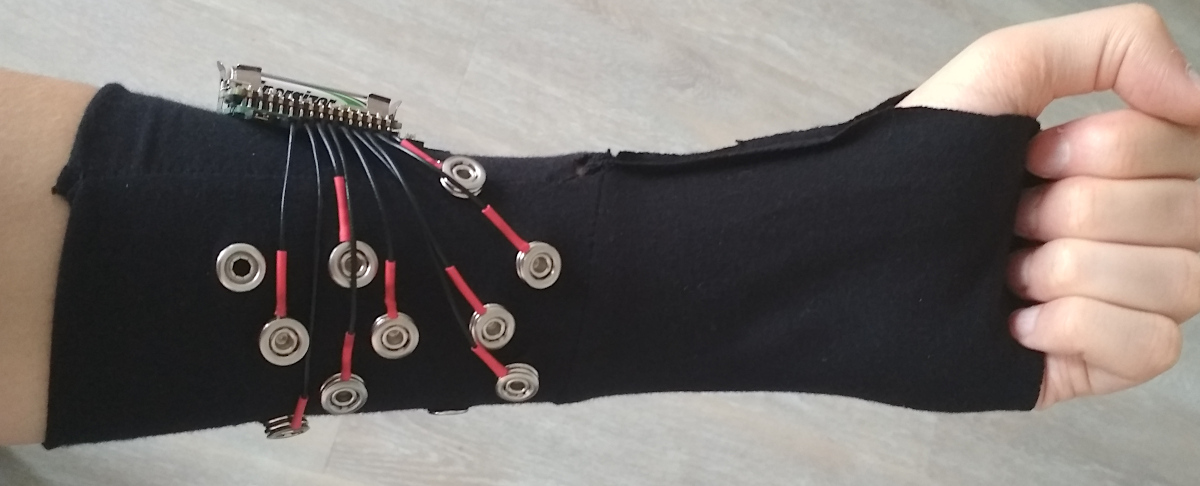

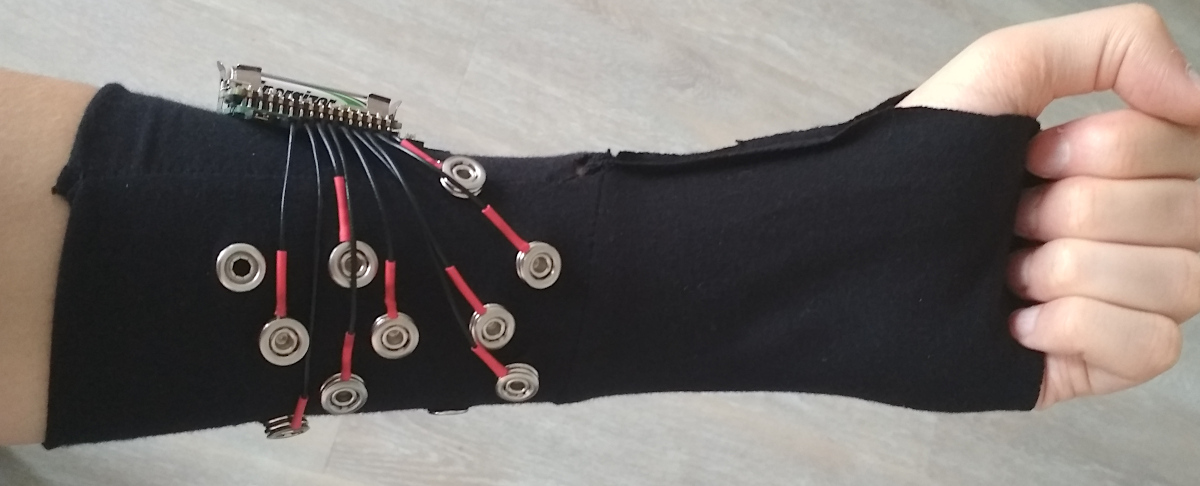

Cyber Wristband of Telepathy +2 [UNIQUE ITEM]

└2021-06-24, by Roman

Power Module 3 finally found a home: Sleeve 4. Looks a bit like a Pip-Boy from the Fallout Series :)

Under the hood there's 9 electrodes (1x ground, 8x signal):

New Frontpage + Logo

└2021-07-06, by Roman

The front page now looks a little more "modern", and I changed the logo from

to

Once again, this was inspired by the System Shock 2 Trioptimum logo.

Neurofeedback: Training in both directions

└2021-07-17, by Roman

For now, the training of neural networks mostly happens on the AI side. The

human makes arm gestures and presses keys on the keyboard. This provides the

input (electrode and

IMU signals) as well

as the output/labels (keyboard actions) to the artificial neural network, which then

learns the correlation between the two through

supervised gradient

descent.

Now I'm looking into how to train both the neural network of the AI as well as

the nervous system of the user through

neurofeedback, that is, by

making the user more aware of their neural signals, which in turn allows them

to fine-tune these.

My hope is that this will make up for the low quality of information that's

available to the AI, due to noise, attenuation, and the low number/quality of

electrodes. The user neither knows what signals the electrodes can access, nor

how to willingly produce movements that create these signals. Some gestures

work well, while others can't be detected at all, so the best bet is to use

forceful gestures with maximal muscle activation. But if there was some sort

of feedback to the user, like a visualization of the data that the neural

network is extracting, the user could focus on the movements that work, and

gradually lower the intensity, perhaps to the point where no actual movement is

required anymore.

Of course there is already some feedback about the signals: The PsyLink

UI shows the amplitude of each electrode in a rolling graph, and the

GNURadio application shows detailed plots of the raw signals, both of which

already help determining which movements will work for gestures and which will

not. But the AI can of course combine, cross-correlate, filter, convolve and

deconvolve the signals, which enables it to extract information that a human

won't see in the raw signal data.

Ultimately, the goal is that the user learns to, on demand, fire off just

enough neurons that PsyLink can pick up the signal and trigger the intended key

press without any visible movement of the arm.

Approach

As described above, simply presenting the user with the raw electrode data is

insufficient. A machine-learning approach will likely be optimal here, to

overcome the preconceptions of a top-down designer. Since we already have an

artificial neural network, why not use that one to generate the visualizations

too?

In my current version of this idea:

- The user needs to invent some arbitrary gesture that should correspond to

the action "Press key 'A'".

- The user is repeatedly asked to perform the gesture by the UI

- At random intervals

- For random durations

- With 2-3 seconds of heads-up warning to account for reaction time

- In between the gestures, the user should perform random other activities,

but never do the gesture without being asked by the UI

- The AI is trained on the fly with

- Electrode signals as input

- A binary label of "Key 'A' pressed" vs. "Key 'A' not pressed" as output

- Each data point is added randomly (80:20) to the training or validation dataset

- After X seconds of collecting data, the AI is trained for Y epochs

- Every Z milliseconds, the AI is asked to predict the output from the current

input, and the neural activations of the last non-output layer of the NN

are presented to the user visually, along with the predicted output.

- The visualization could be a heatmap or a scatterplot, for example

- The visualization should cover a large dynamic range (both small changes

and large changes to the values should be easily visible)

- Using the feedback, the user can tweak their gesture as desired, to e.g.

- Minimize the movement required to trigger the key

- Maximize the reliability with which the key press is predicted

- Over time, old data is dropped from the NN training to refine the

visualization and to keep the training time short.

Once the user is ready, they can add a second action like "Press key 'B'" and

so on.

Batch Update

└2021-11-30, by Roman

I haven't been posting recently because I've been focusing on other areas of my

life, but there has still been progress with PsyLink:

Prototype 6 improvements

I redesigned Power Module 3 to be more easily hand-solderable by enlarging the solder pads and adding thermal clearances to some of the filled copper areas. (The copper tracks to several pads were so wide that the heat of the solder iron was dissipating too fast into the copper, and the pads were not heating up properly). The result is Power Module 3.1.

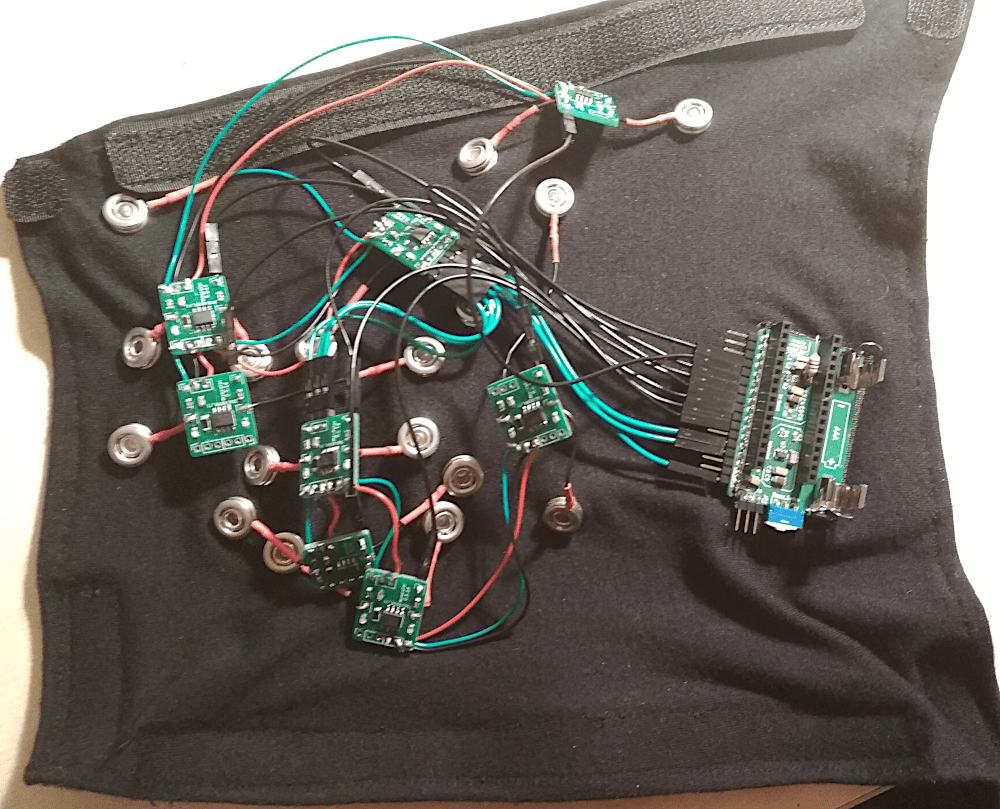

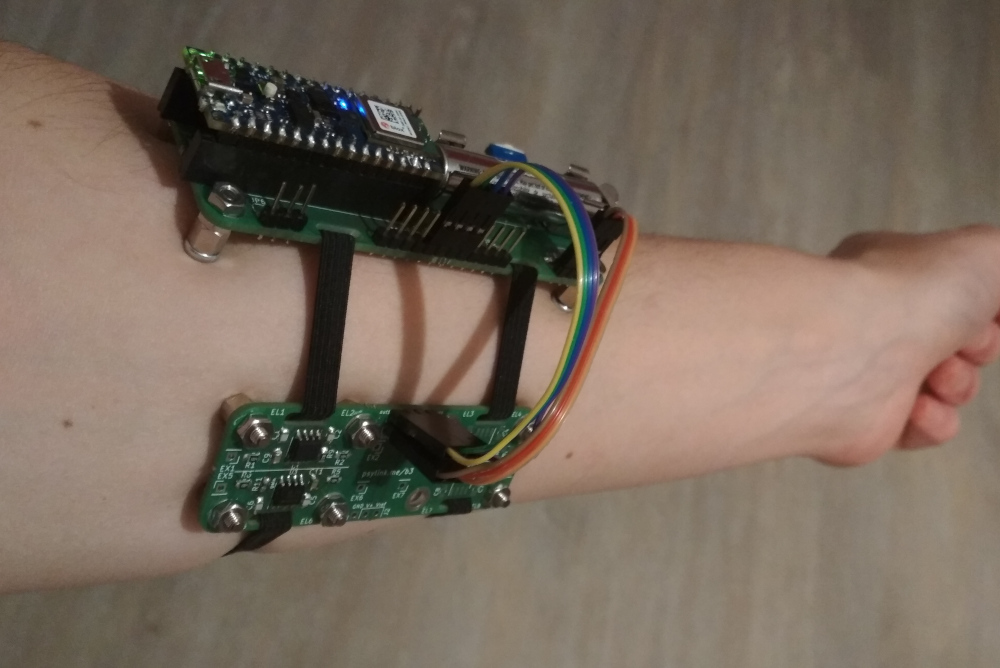

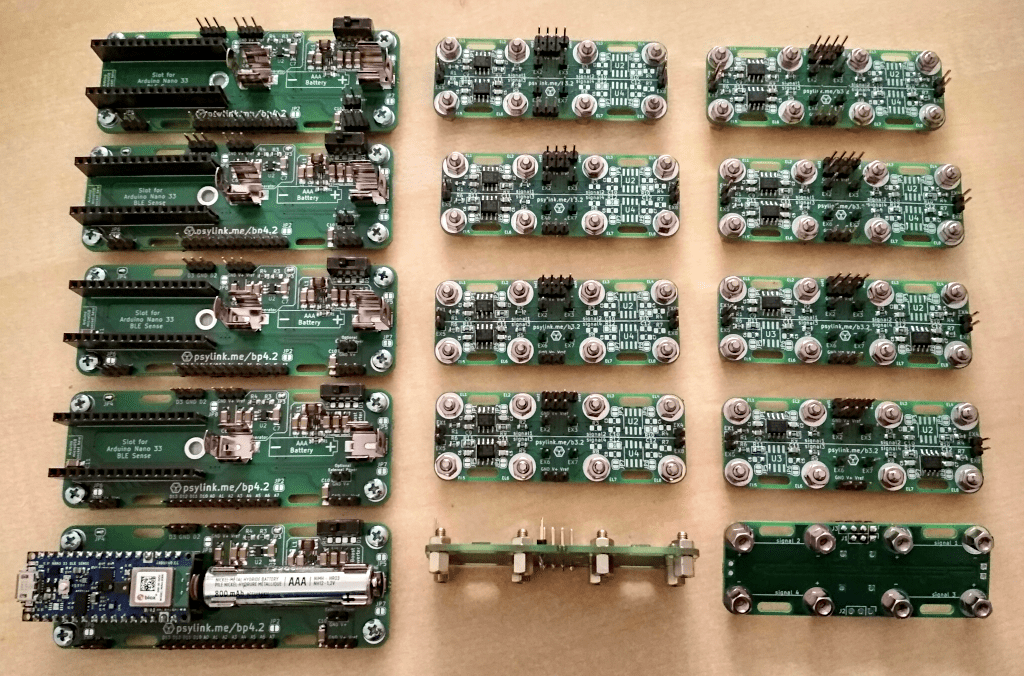

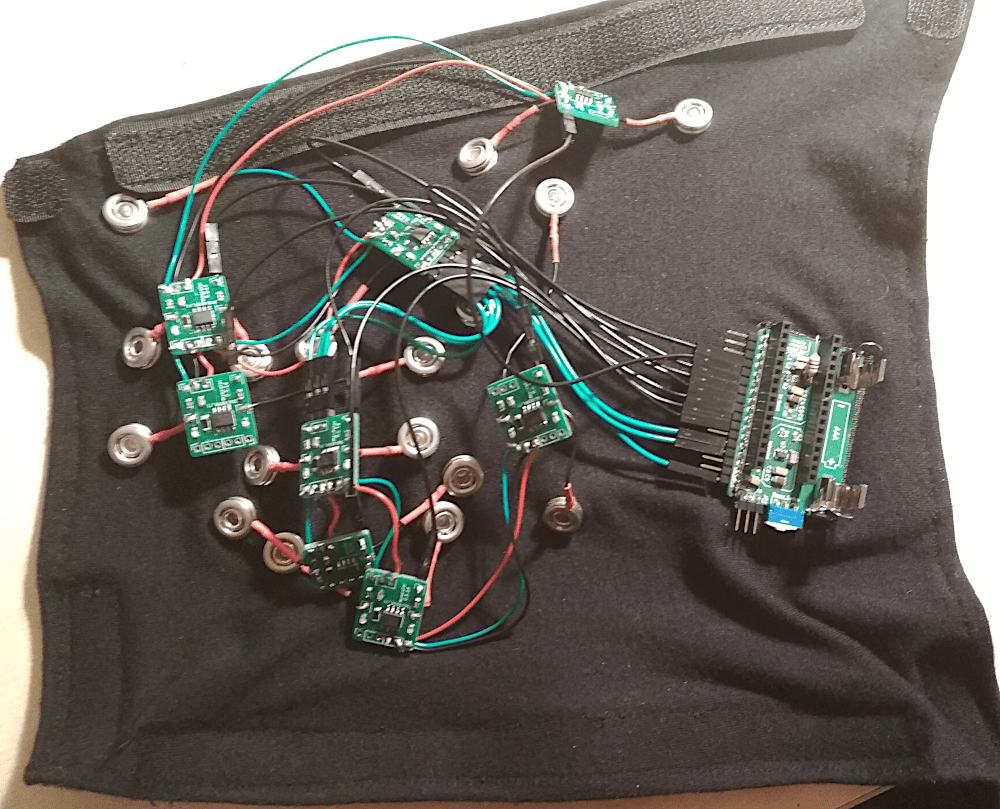

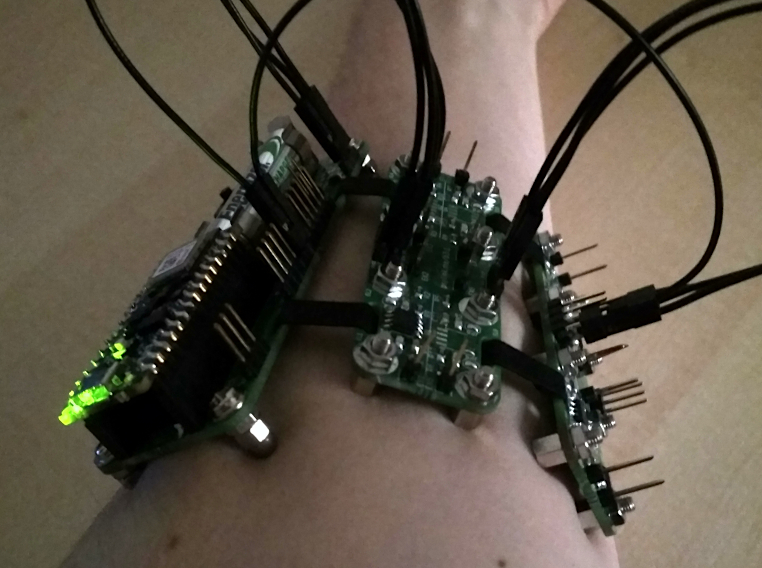

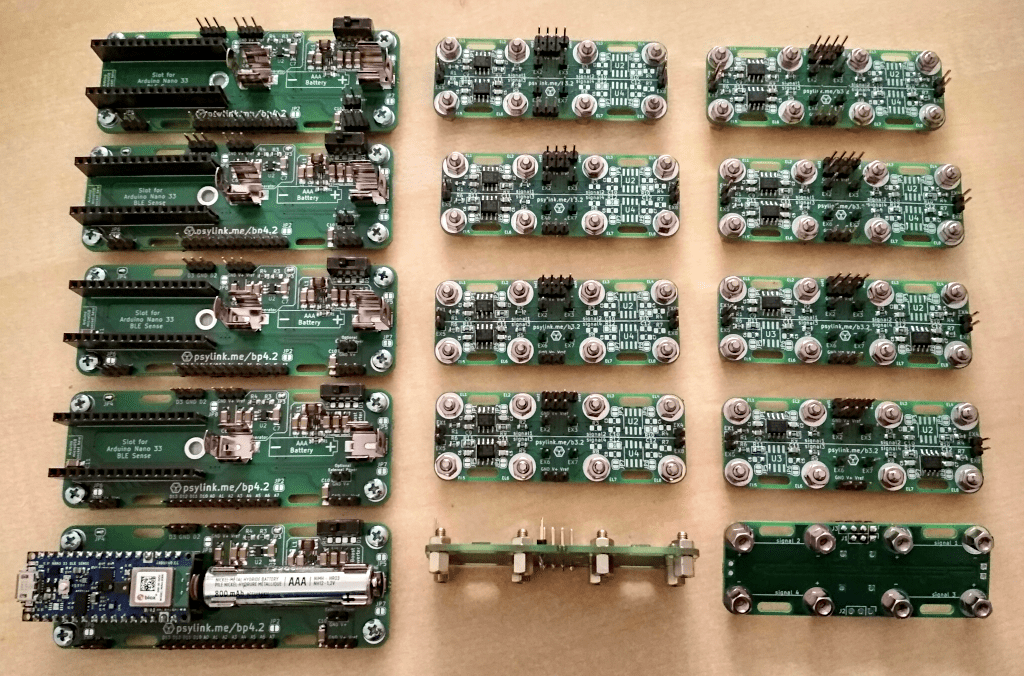

Prototype 7

PerlinWarp reached out to me, and after some fruitful conversations, I build a Prototype 7 for him for research purposes. It's a hybrid of Prototype 4 and Prototype 6 which combines the advanced Power Module 3 with a cluster of Electrode Module 1 attached to Sleeve 3.

The assembly of the Prototype 7 took a full 20 hours of mindless labor,

so I had a LOT of time to think about improvements to the design that would

make it easier to assemble:

- Instead of having small boards for differential amplifiers that have to be

tediously connected with three fragile wires, bulk four of them up in a

single board.

- Instead of having a piece of custom-tailored fabric with precisely placed

electrodes, use electrodes made of metal screw-like parts that fit right

on to the PCB. The PCBs are held together with a rubber band that presses

the electrodes tightly to the skin.

- Made Power Module 3 more easily hand-solderable (described above)

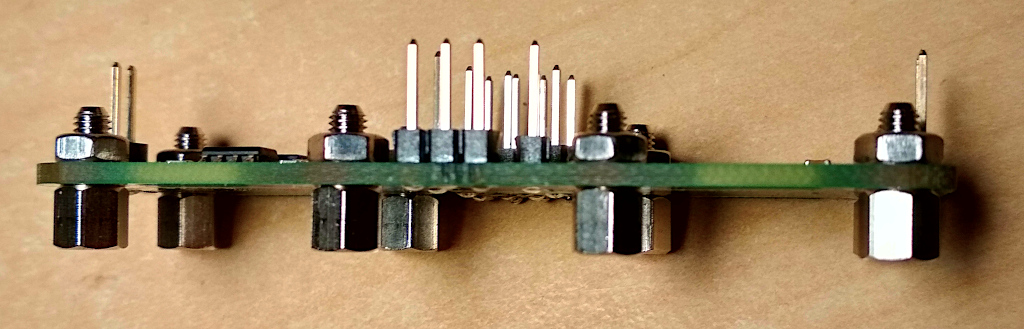

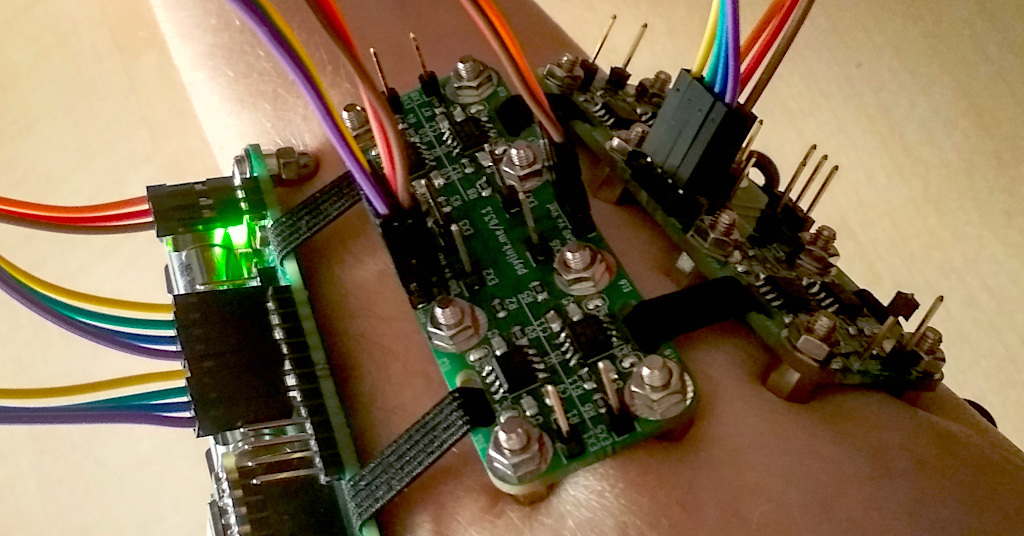

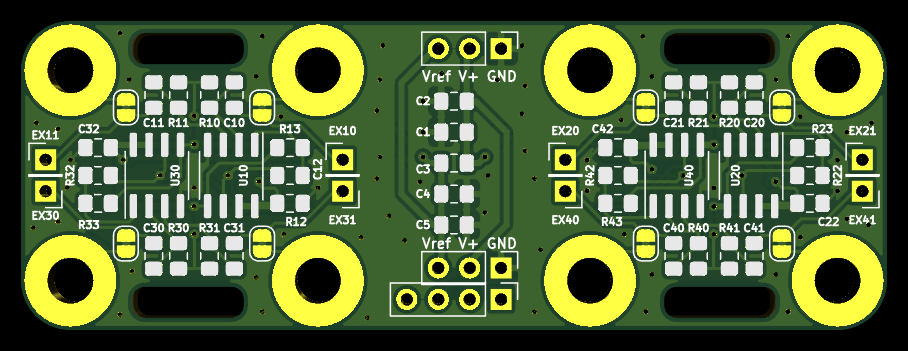

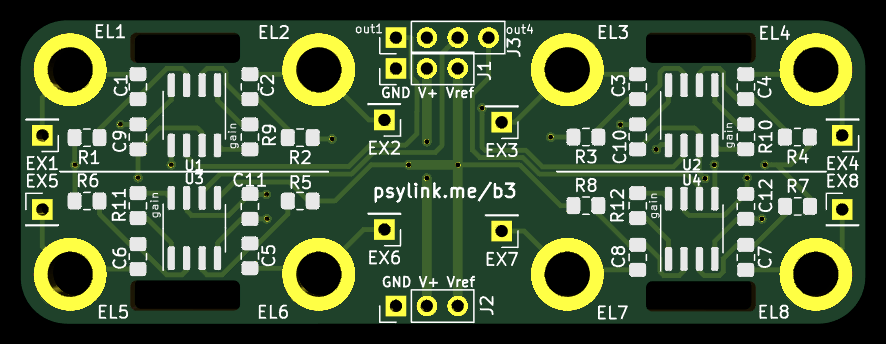

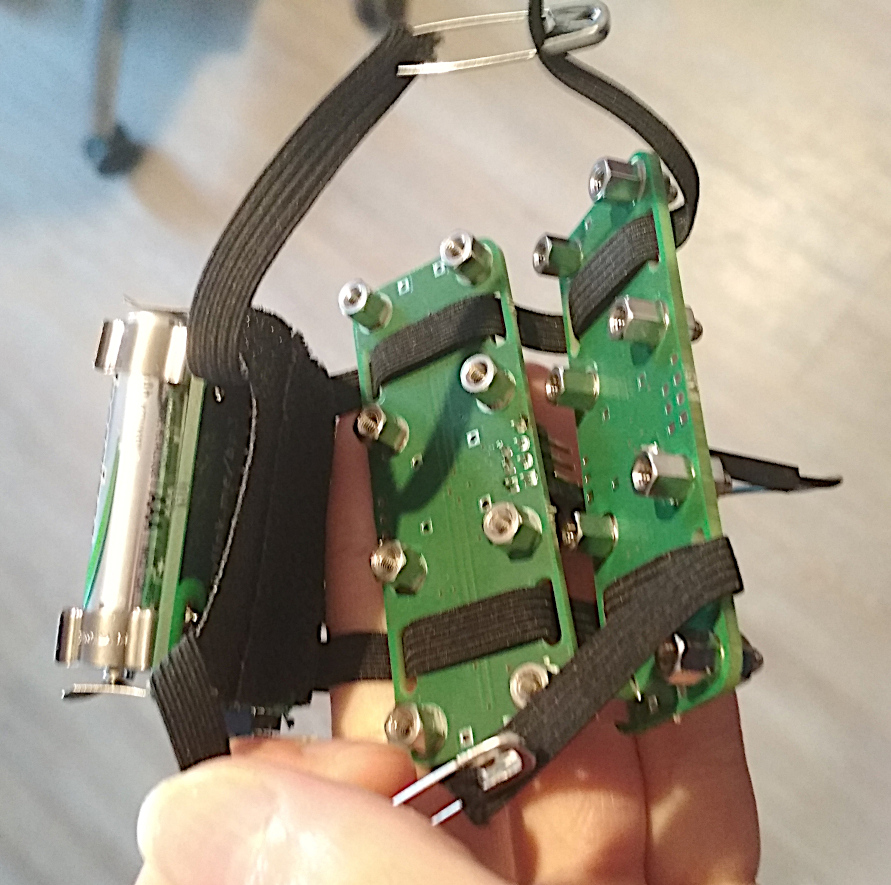

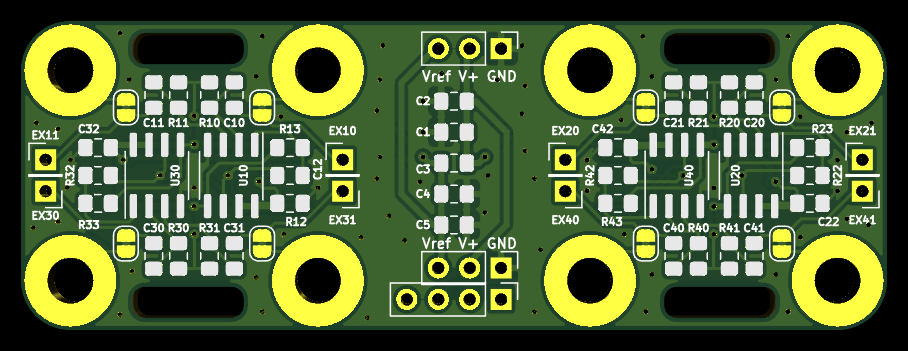

Prototype 8 (WIP)

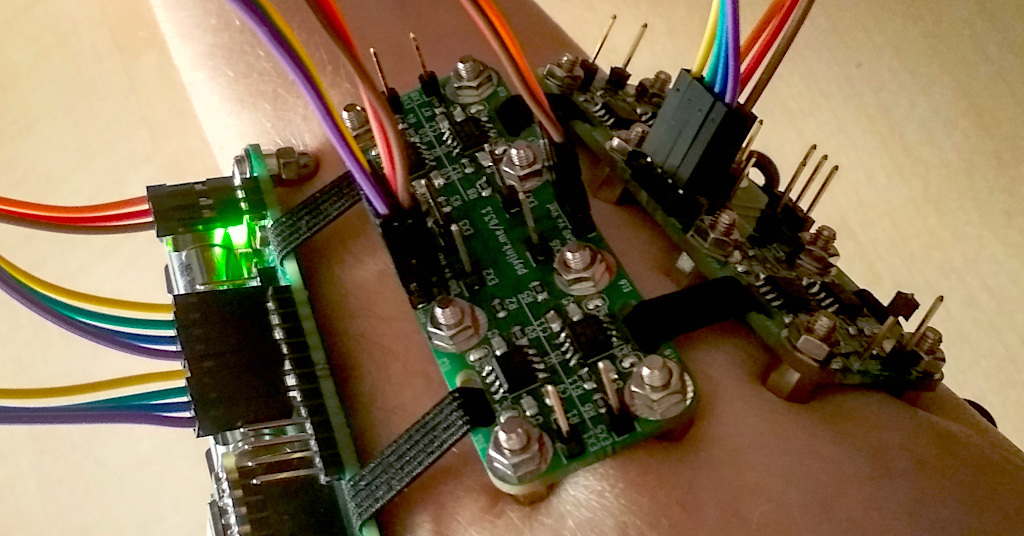

The 8th prototype implements those changes, resulting in a device purely made

of PCBs connected by rubber bands and wires. These PCBs rest on the skin on

legs of metal, which double as the electrodes.

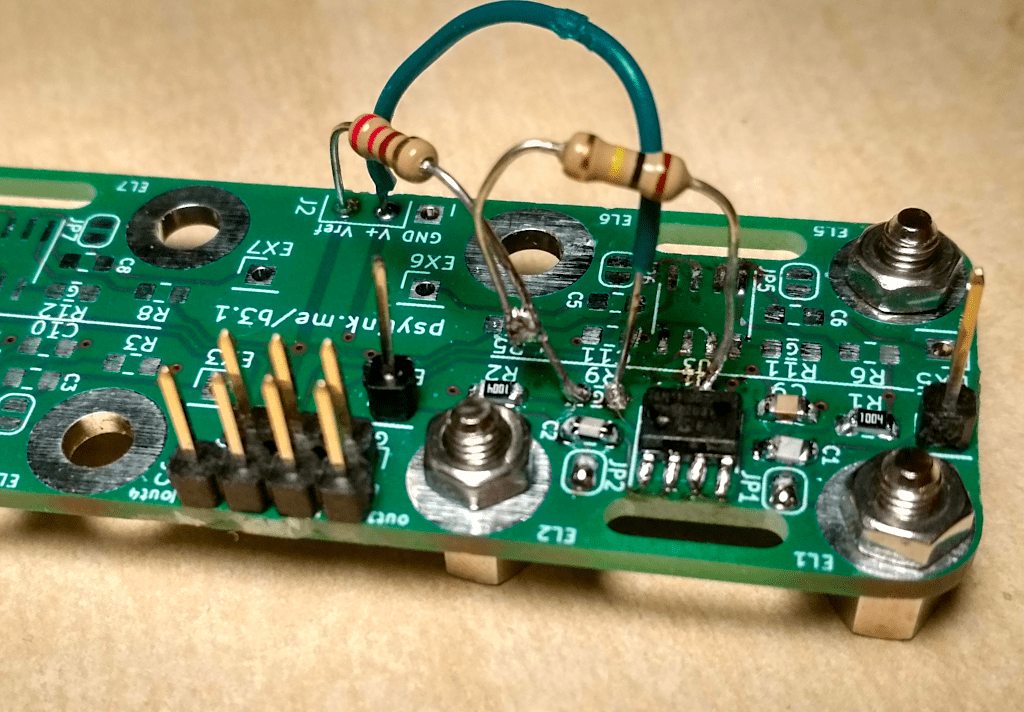

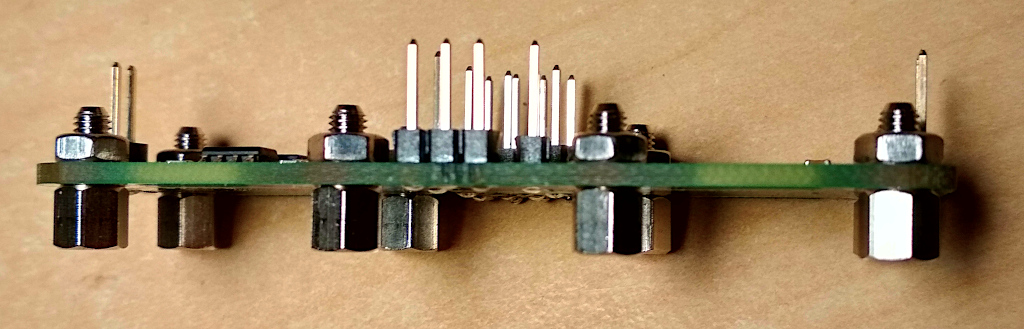

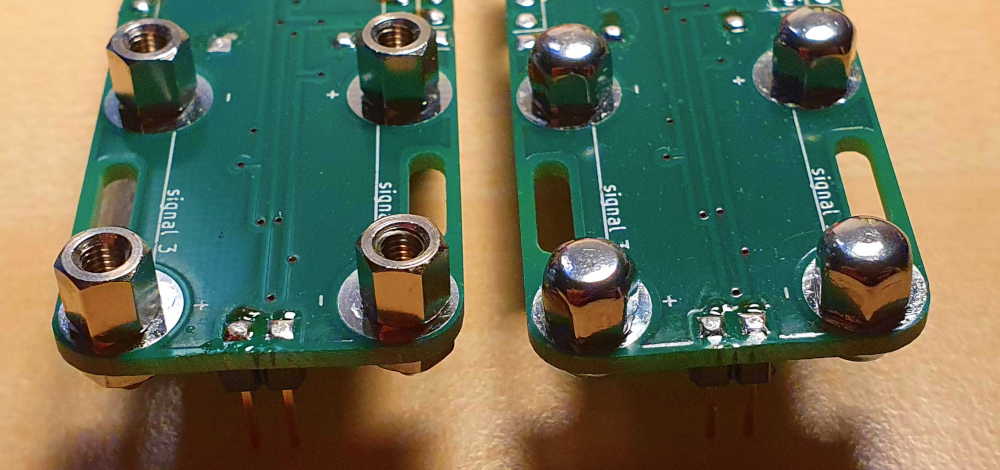

As of now, only the differential amplifiers are finished. The circuit for

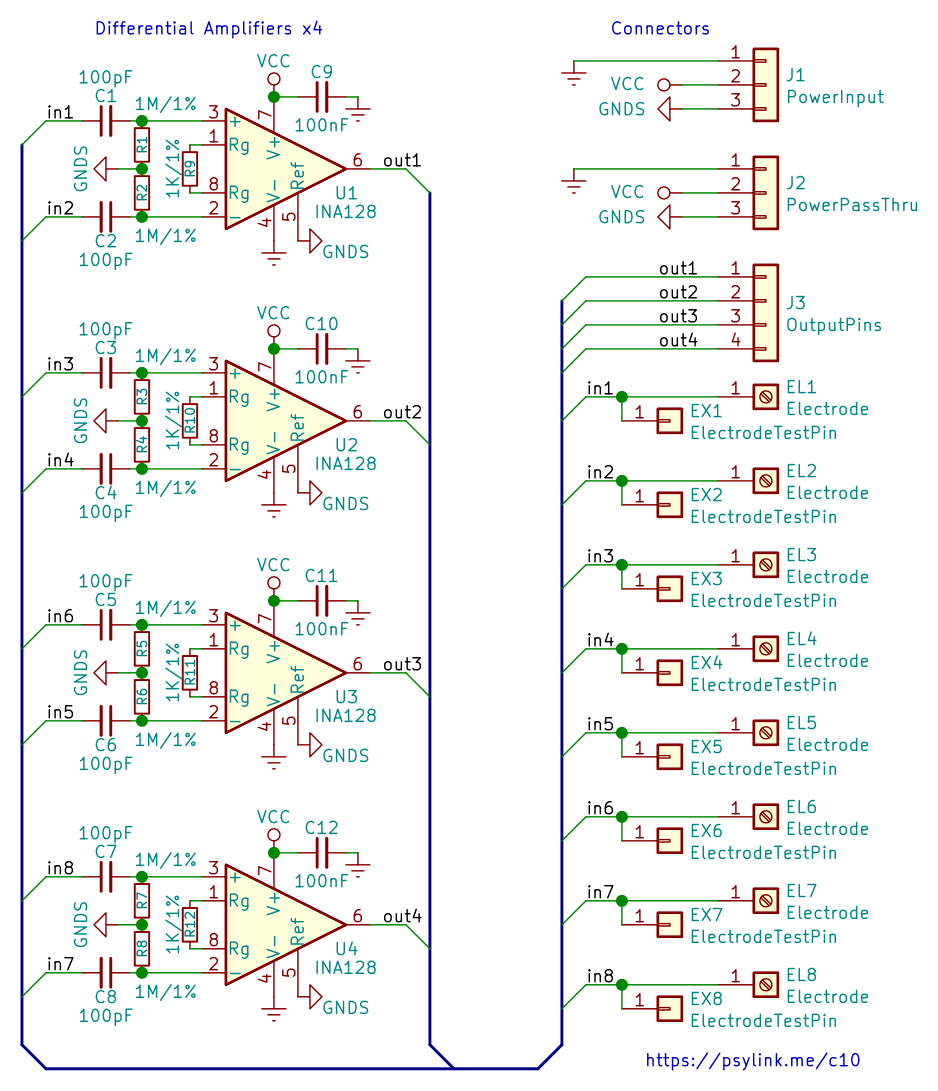

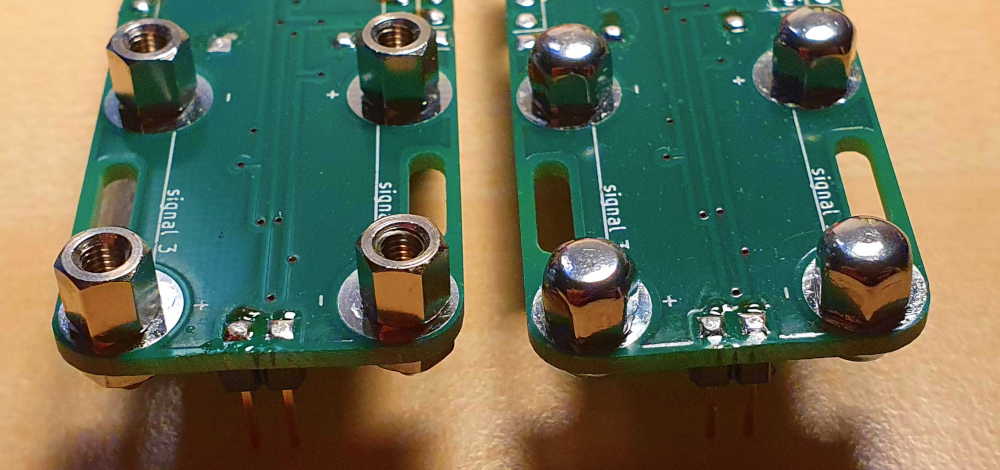

these is Circuit 10 (electrodes):

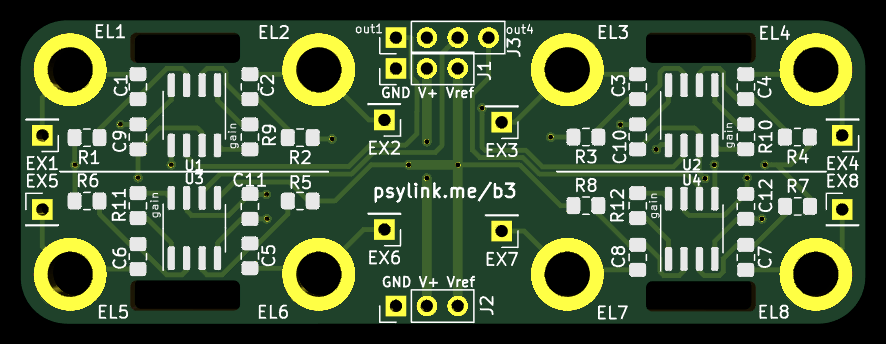

The front-side of the Electrode Module 3:

The four wide holes in the board are connection points for rubber bands, and

the eight round metal-plated holes are mounting points the electrodes. These

consist of a screw on one side, a nut on the other, holding both metal pieces

tightly in place.

The electrodes can be spacer screws like these or dome nuts like these. While the spacer screws seem to pick up a better signal, the dome nuts are considerably more comfortable thanks to the rounded cap, so I think I'll stick with these for now.

Dome nuts are also called "hutmutter" in German, which translates to "hut's

mother" (my nickname is hut), so just because of that fact, I had to try them

out.

Additionally, one can use the pins EX1 through EX8 to connect arbitrary

external electrodes.

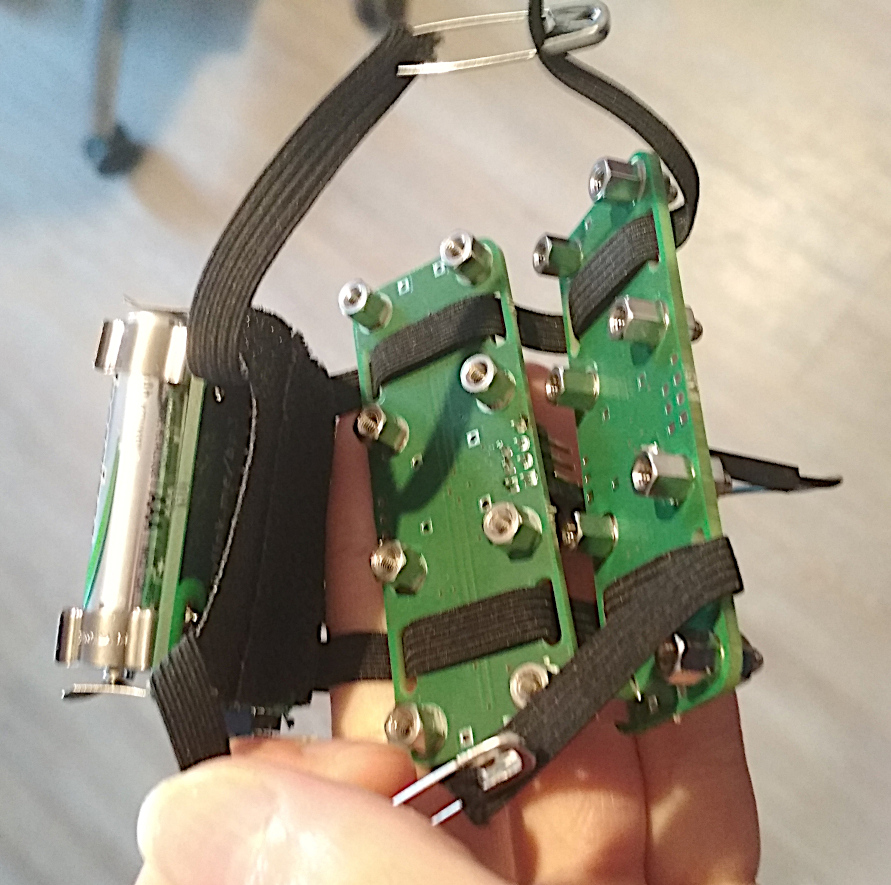

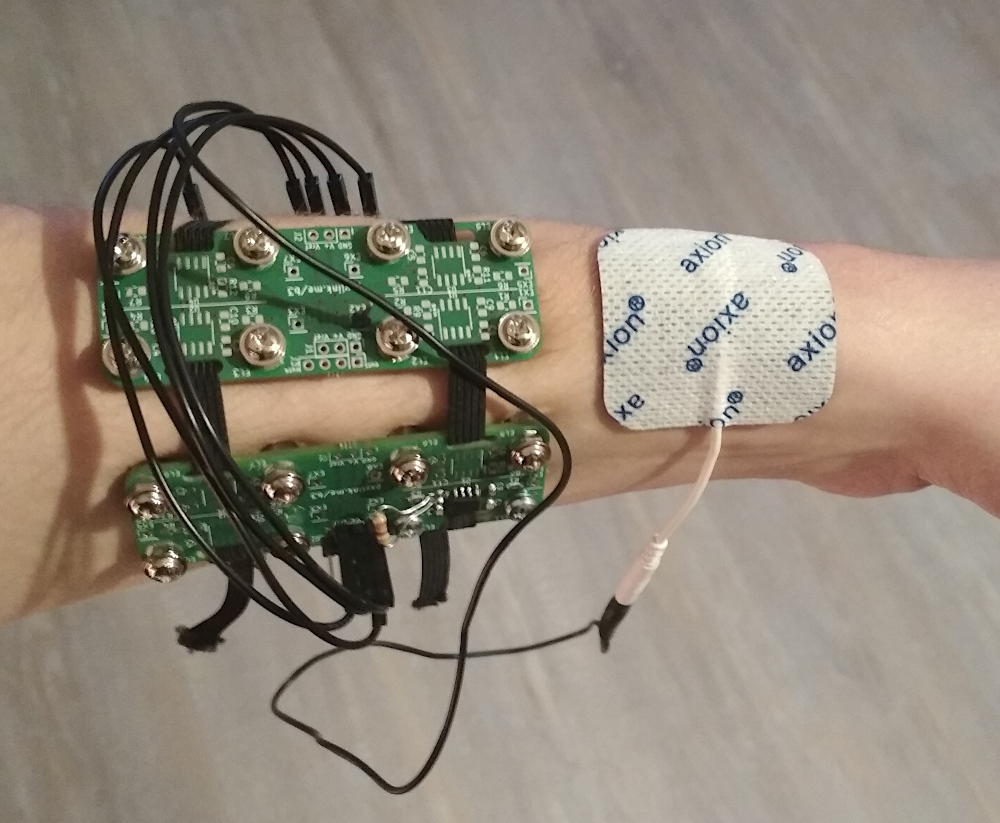

A first prototype using Electrode Module 3 and Power Module 3.1 (with an

improvised rubber band mounting mechanism) can be seen here:

I played around with using off-the-shelf wet EMS (electric muscle stimulation)

electrodes for the ground electrode, since good connectivity for the ground

electrode is important for a good signal.

I did not find an improvement in the signal though, perhaps wet electrodes are

not worth it.

Finally, the global microchip shortage has affected this project as well, and I could not find any sources for the power converter chips (TPS61220 DCKR) that boost the battery voltage of 1.2V to the required 5.0V. I still have some legit chips left, but in the long term, I need more of these, so I acquired some chips from Shenzhen via AliExpress. They have been advertised as "Original new, 100% quality", so what could POSSIBLY go wrong? But I tried them out, and they actually do their job quite nicely.

Future plans

The power module is currently only clumsily attached to the rubber band. The finished Prototype 8 will need a power module that's more compatible with the Electrode Module 3, by making it as long as the Electrode Module 3, and either by adding rubber band mounting holes, or by adding pin headers so that it can be stacked on top of the amplifier board, which would reduce the number of dangling wires as well.

I will also try out cheaper differential amplifiers to reduce the total cost of the device from ~70€ to ~30€ (excluding the ~39€ for the Arduino Nano 33 BLE Sense).

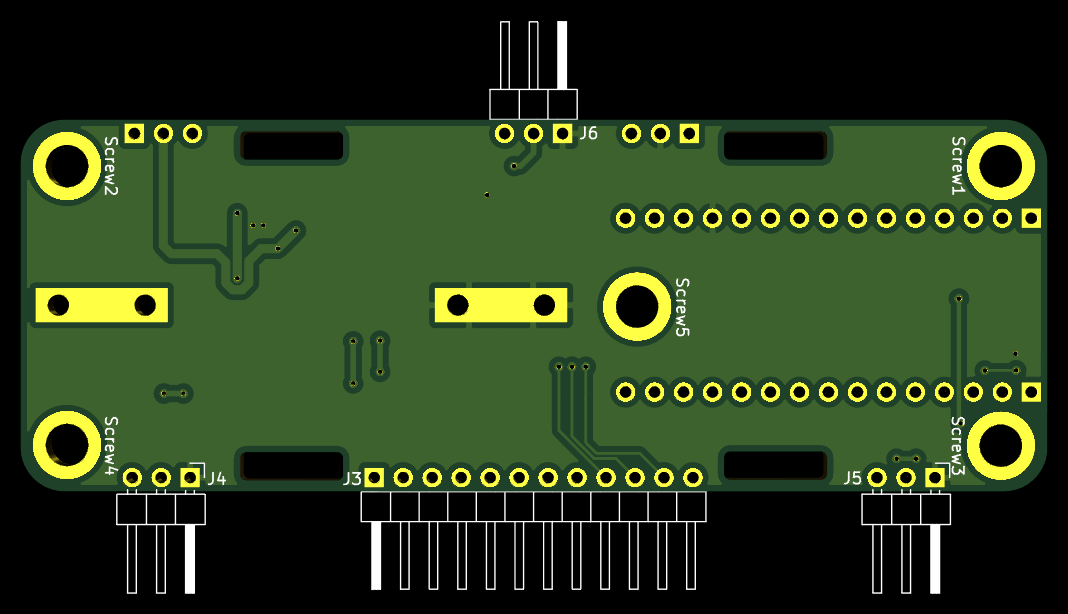

Power Module 4

└2021-12-15, by Roman

Prototype 8 needs a matching power module. I can't continue to awkwardly

stuff the rubber band between the velcro and the PCB of Power Module 3 like

this:

We need a PCB with proper rubber band holes and screw mounting points, so it

can be worn along the radius

bone

with about 2x Electrode Module 3 beside it.

Unfortunately the large dimensions of the Arduino and the battery make it a

little difficult. There's several options to do this, but none of them are

perfect:

- Place Arduino and battery beside each other like in Power Module 3

and either...

- make the board ~15mm longer to fit the holes.

- make the board ~12mm wider to fit the holes.

- Downside: It would be too wide to comfortably fit on the radius bone

- Downside of both options: it might feel unbalanced when worn on the side of the arm, because the heavy battery moves the center of mass off to the side

- Place Arduino and battery on top of each other, with pin sockets for the arduino that are taller than the battery, then make the board the size of Electrode Module 3 to fit the holes

- Downside: It might be hard to acquire pin sockets that tall

- Downside: Little space left for the holes and the remaining components, but might work

- Place Arduino and battery in a line next to each other and make the board 20mm longer and 8mm wider than Electrode Module 3 to fit the holes.

- Downside: The rubber bands are relatively close to the center, reducing the force with which the far ends of the board are pressed onto the skin

- Downside: The large dimensions might make it too bulky

- Remove the Arduino and solder the NINA-B306 bluetooth module of the Arduino onto the board directly, along with all the peripherals I need

- Downside: Unnecessary complexity

- Downside: More difficult soldering

- Instead of adding any holes, just stack the board on top of a Electrode Module 3 and use its screws and rubber band holes for physical support. (Thanks to PerlinWarp for that idea!)

- Downside: Would require a redesign of Electrode Module 3

- Downside: The height of the prototype might make it feel unbalanced

- Downside: The board would have be either wider or longer than the Electrode Module 3 due to the dimensions of the Arduino and battery. As a result, it would stick out to the sides, unless I enlarge the electrode board as well.

In the end I chose option 3 for simplicity reasons, and because the downsides

seemed the most acceptable. This also gives me a lot of space on the PCB which

is currently not needed, but may be used for analog multiplexing later on, to

allow supporting more than 8 electrodes.

I am quite tempted by option 2 though, it would make for a really compact

board. Maybe I give it a try later (if I ever find a source for 1x15 pin

sockets that are 14mm+ tall and 2.54mm spaced apart.)

Here is the resulting board. As you see, I also added a screw mounting hole in

the center, which should point right at the bone, which perhaps makes for a

great ground electrode. Any of the screws can be used as ground electrodes

though, simply by closing their respective solder jumper. I will try out

various combinations to see which one is best.

The matching circuit:

I ordered the production of this board already, and I'm excited to see if it

will work out like I imagine. :)

Fun story on the side: I ordered the boards on Aisler,

and they let you change the PCB design for free until it hits production. This

time, I had a couple of hours left, which I used to make a couple of

adjustments here and there, until I was happy and went to sleep. After 3 hours

I woke up, with racing thoughts, and I couldn't really fall asleep again (which

happens very rarely). After laying awake for 2 hours, it occurred to me that I

should run the automatic PCB layout check of KiCad once again to test my board

for obvious mistakes. Of course I had run the check before submitting my

order, and several times after doing my various modifications. But as it

turned out, I had indeed forgotten to run it on the final version, and there

were multiple errors too! Several unconnected nodes and some copper tracks

that were too close to each other. Luckily I caught this just a couple minutes

before my time for free modification ran out, and fixed it just in time.

Thanks insomnia.

INA155 Instrumentation Amplifier

└2021-12-16, by Roman

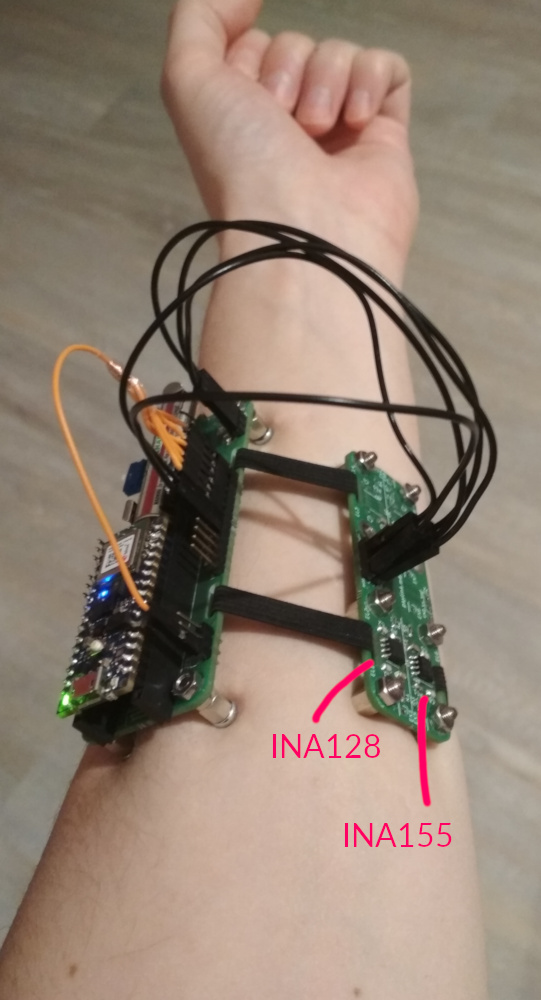

I tried replacing the INA128 chips on the

Electrode Module 3 with INA155 chips

with a Gain of 50, and it works just fine :) The signal even looks a little bit

cleaner than with the INA128, though I don't have good metrics to decide which

one is better overall. They both have the same PCB footprint so I didn't even

have to change the board design :)

This is good news. If I buy the INA155 chips in bulk (250+), they would cost

~1.75€ each (and I currently pay ~5.65€ per INA128), which would bring the

material cost of the whole product down from ~60€ to ~30€ plus

Arduino (~38€) plus shipment. Even if the INA155 is slightly worse, that's

totally worth it.

At this price, it would even be affordable to use more than 8 signals (with

additional analog multiplexing, since the Arduino only has 8 analog inputs)

and wear more than two Electrode Module 3 at the same time.

Another big plus is that INA155 chips can easily work with a supply voltage of

3.3V!! And I wouldn't need to boost the battery voltage all the way up to 5V

anymore, which is probably not very power efficient.

CORRECTION

I did some more tests and concluded that with the electrodes that I'm currently

using, the maximum gain of INA155 is not high enough, and I have to

either find better electrodes, add extra amplifiers, or switch back to INA128

for the time being. For now, the relatively expensive INA128s will have to do.

But hey, the current electrodes are literally just... plain metal spacer

screws, so there is DEFINITELY room for improvement.

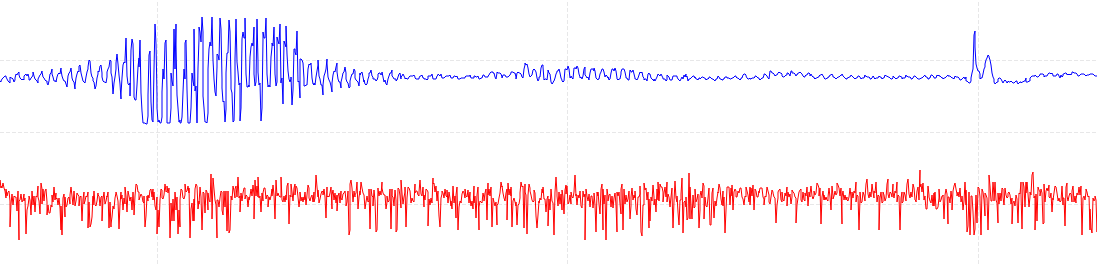

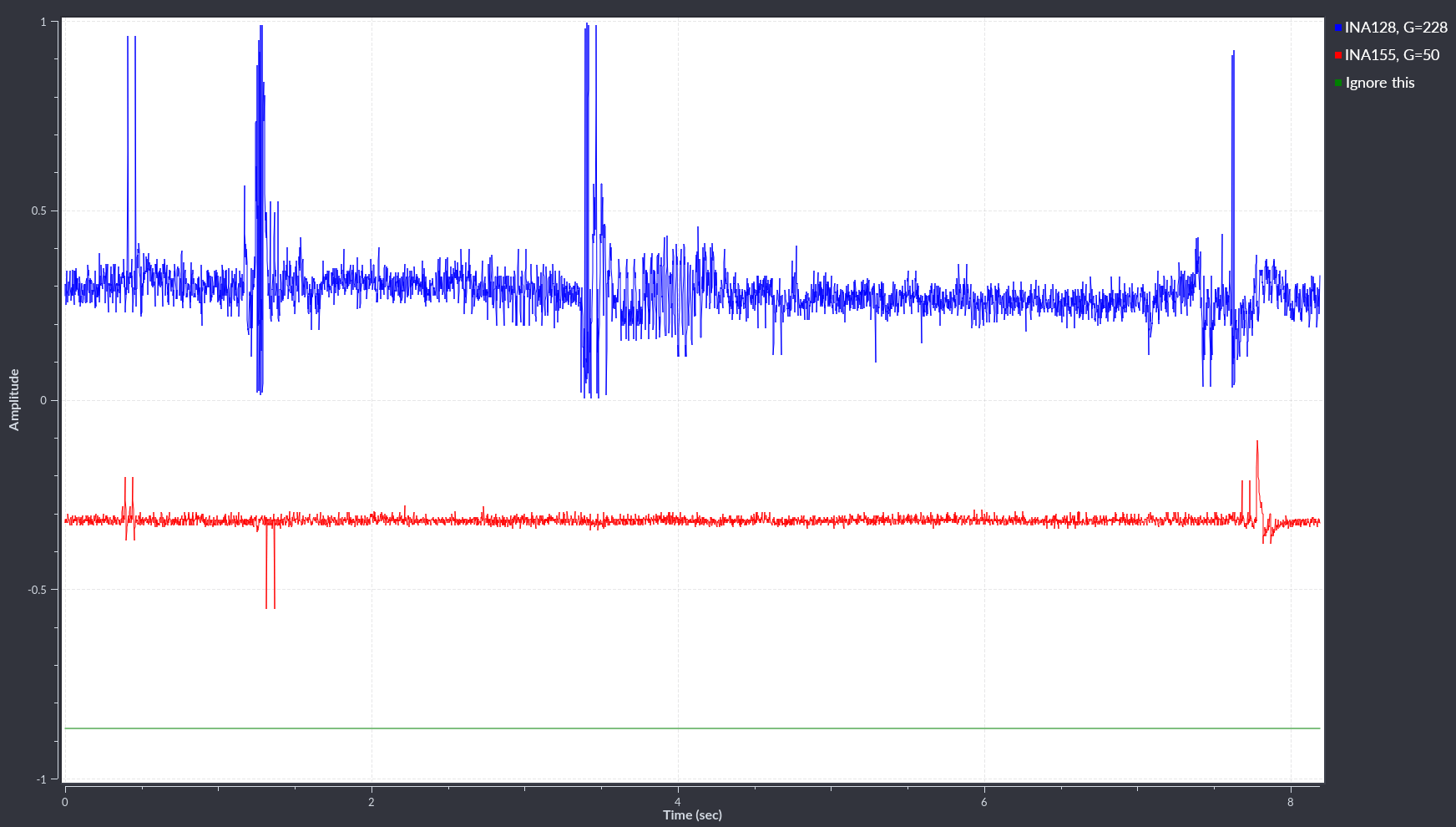

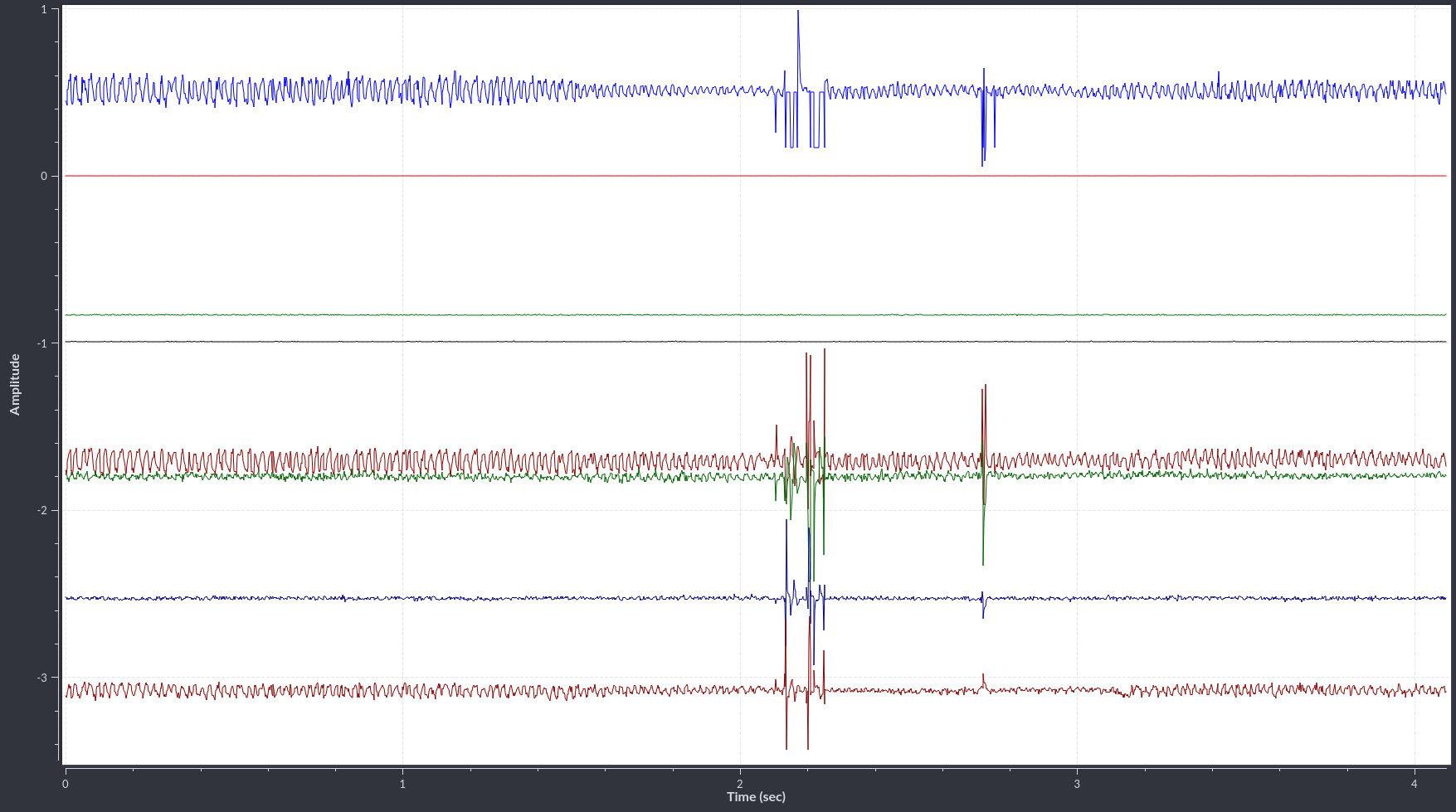

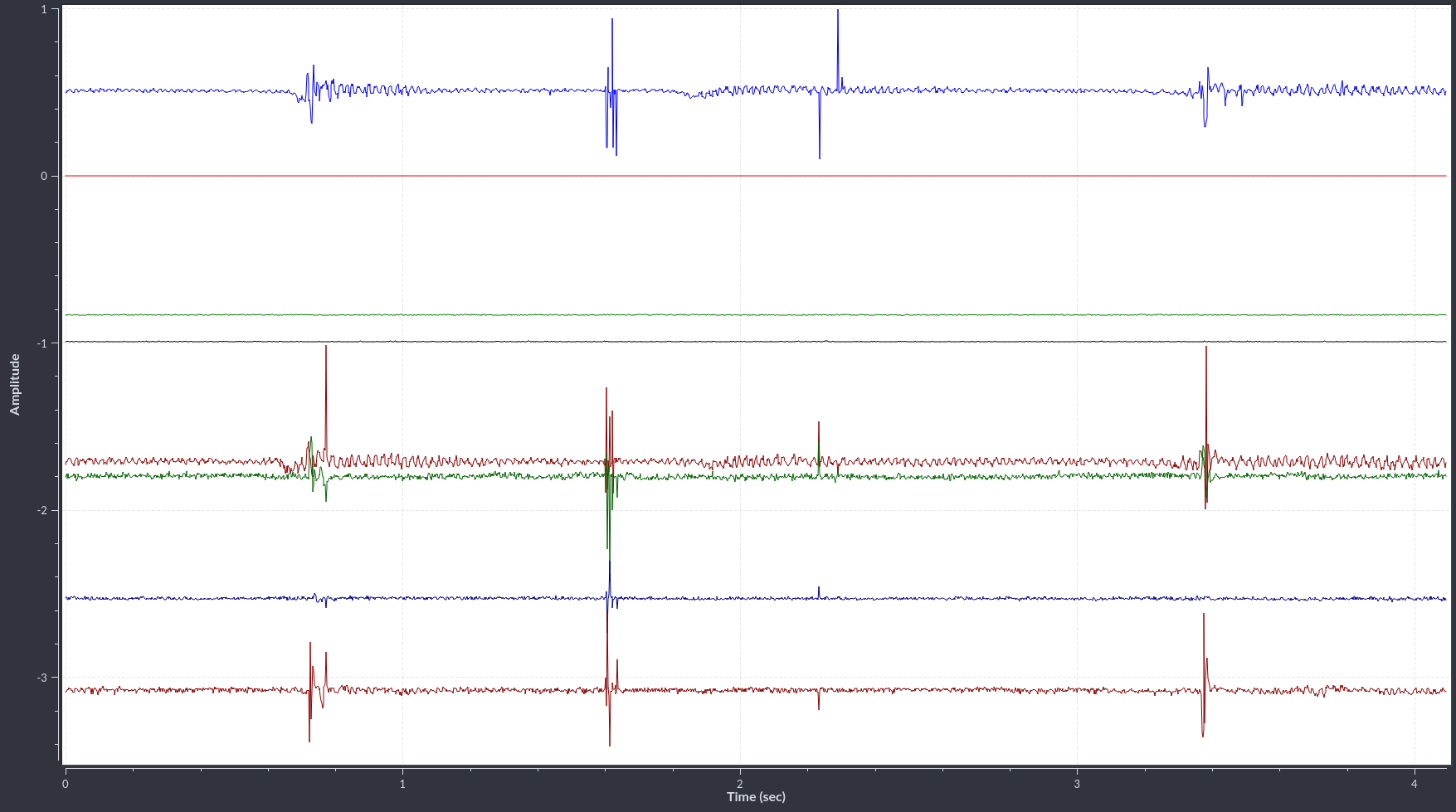

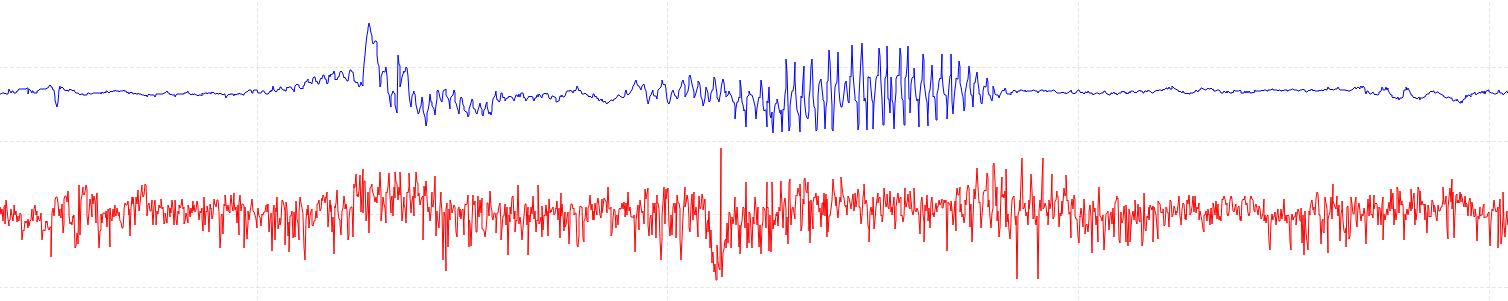

Here are some pictures of electrode placement and resulting signals, where you

can see that the INA128 (blue line) shows considerably more features:

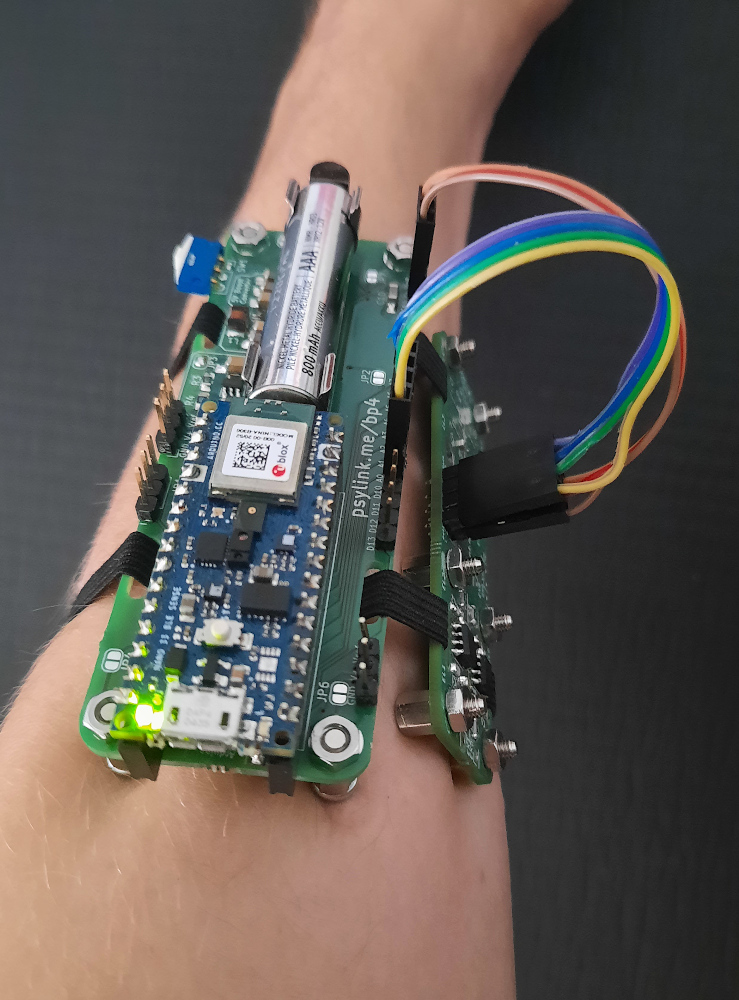

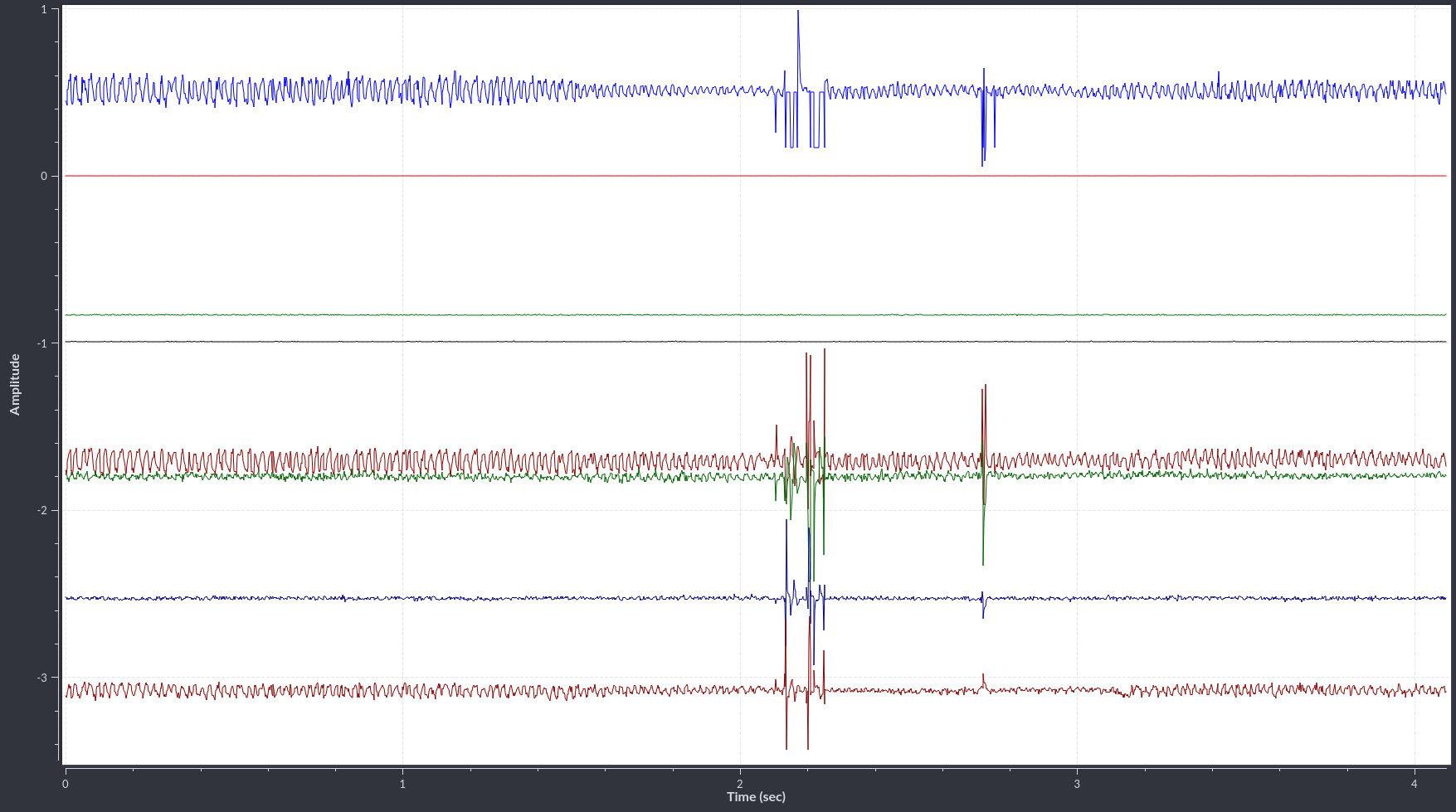

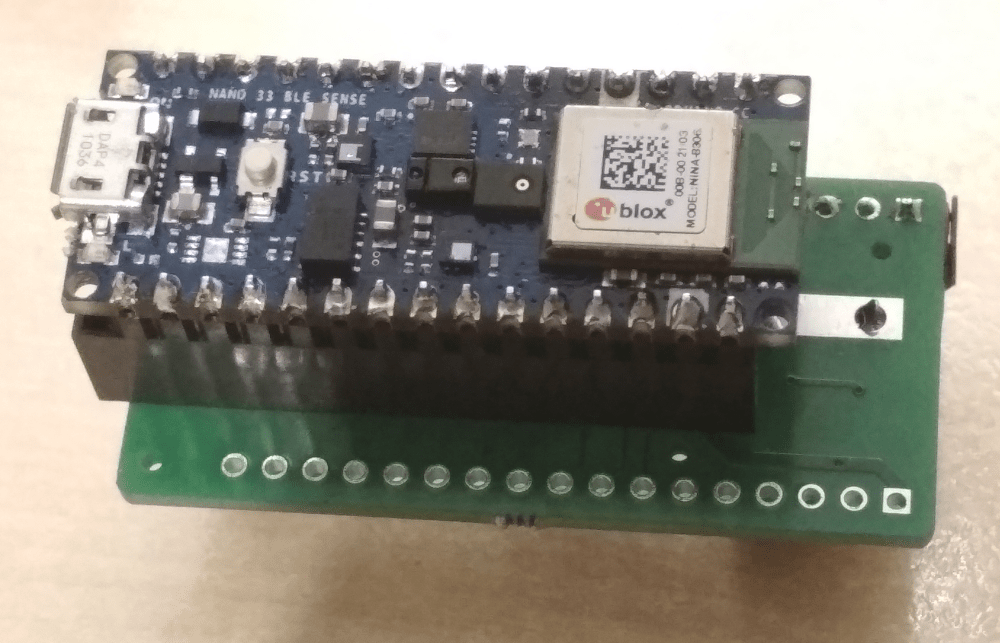

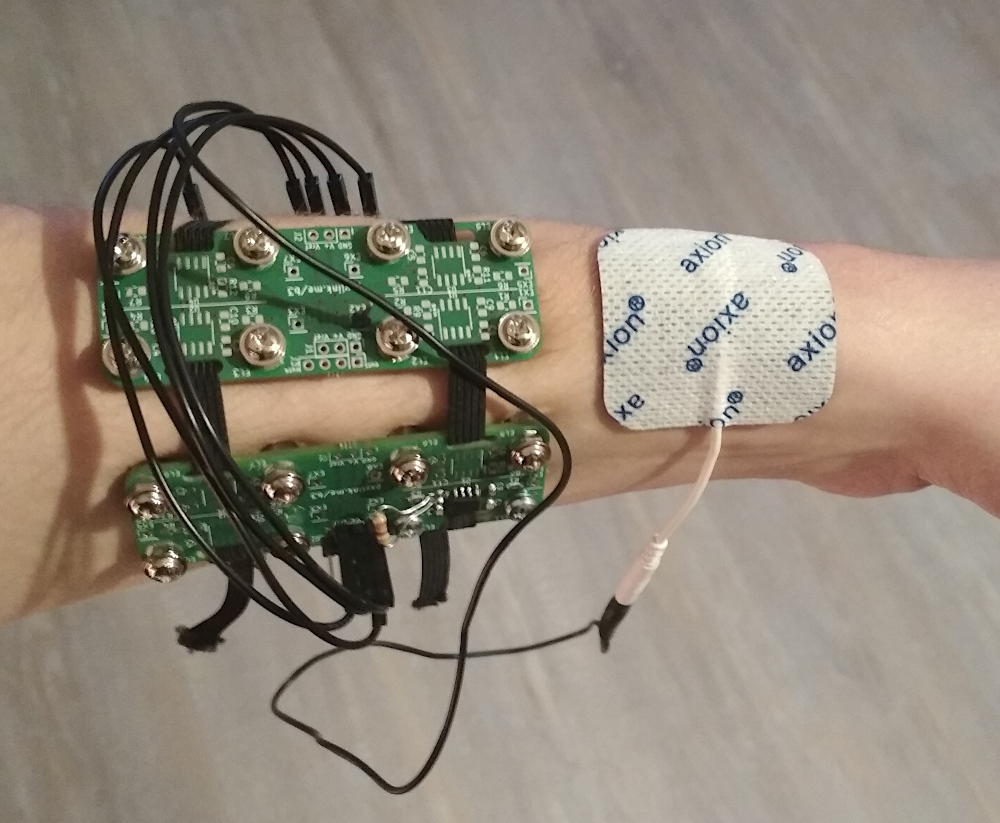

Prototype 8

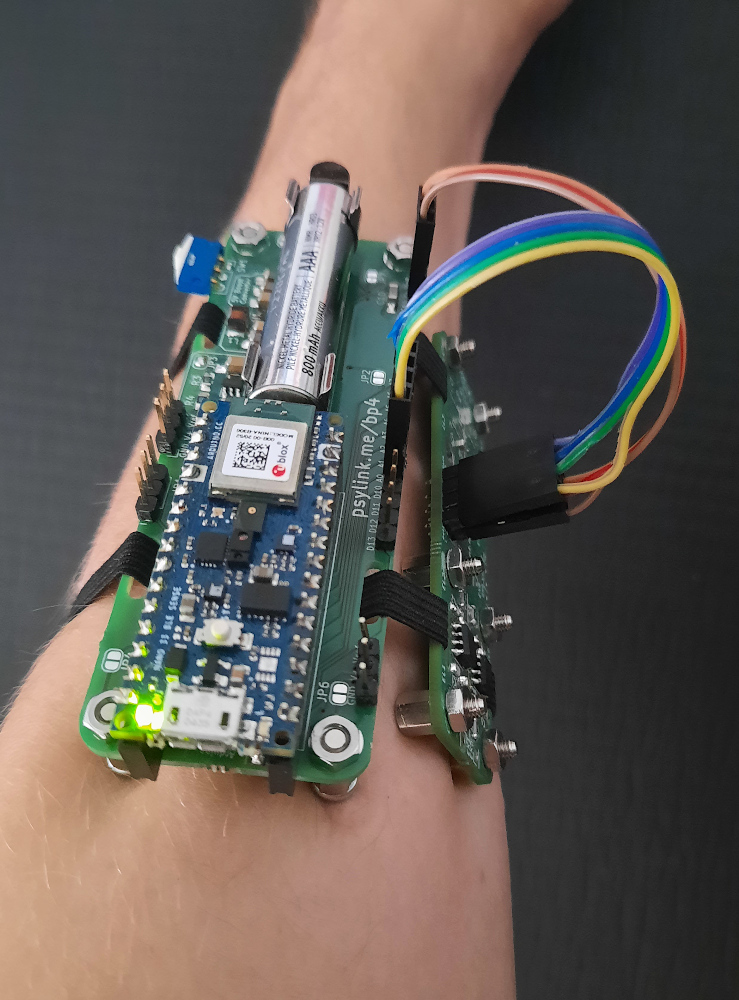

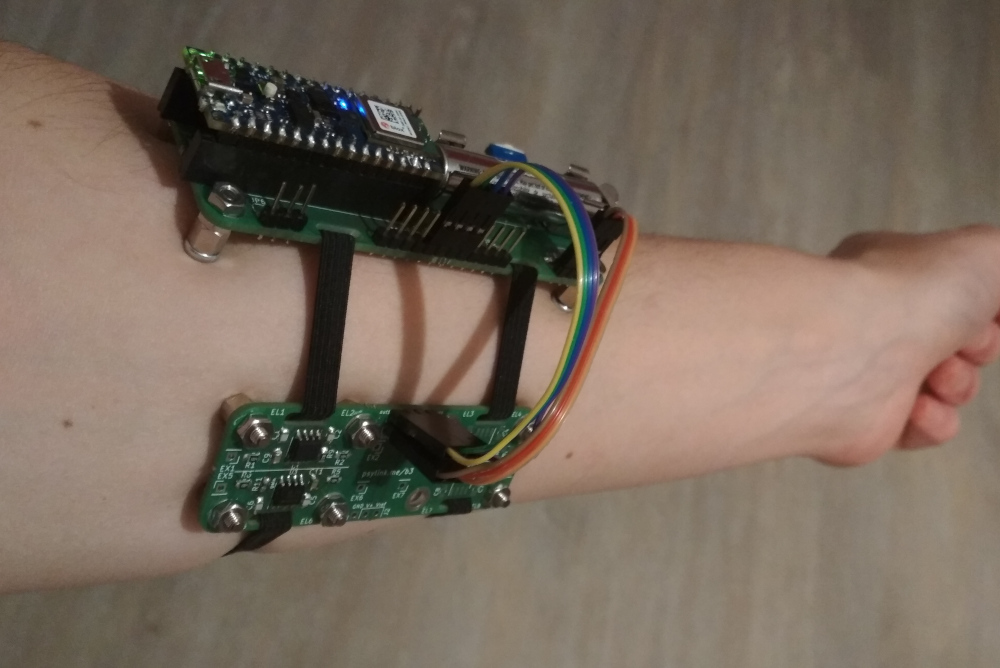

└2021-12-18, by Roman

The order of the PCB of Power Module 4 has arrived, and so all the

parts for Prototype 8 are finally here :) After some assembly (and

crimping of some rainbow-colored connectors that look a little neater than

those stray black wires from previous photos), this is the final picture:

And another picture:

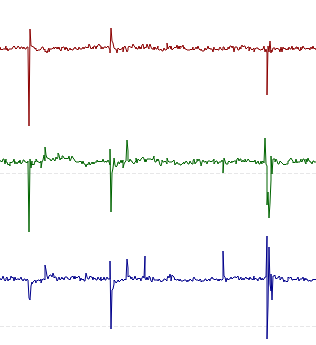

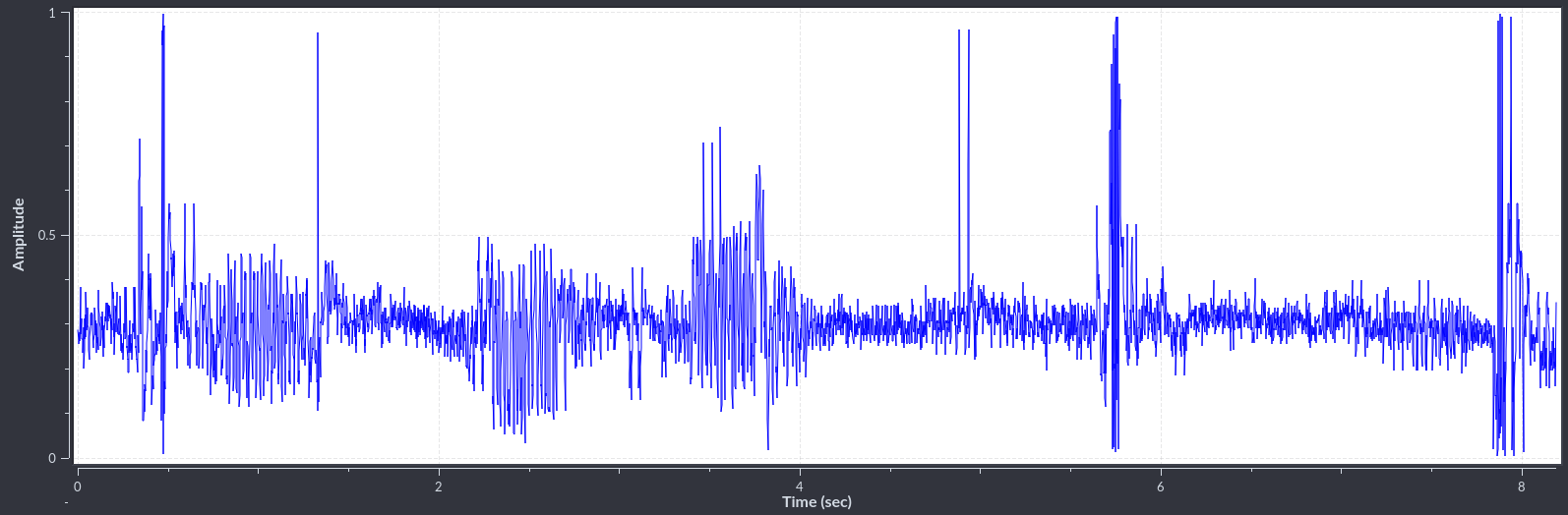

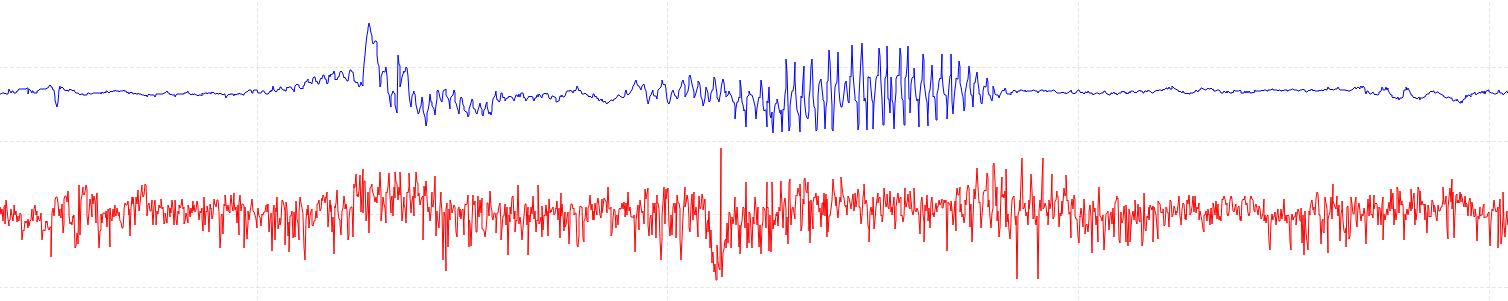

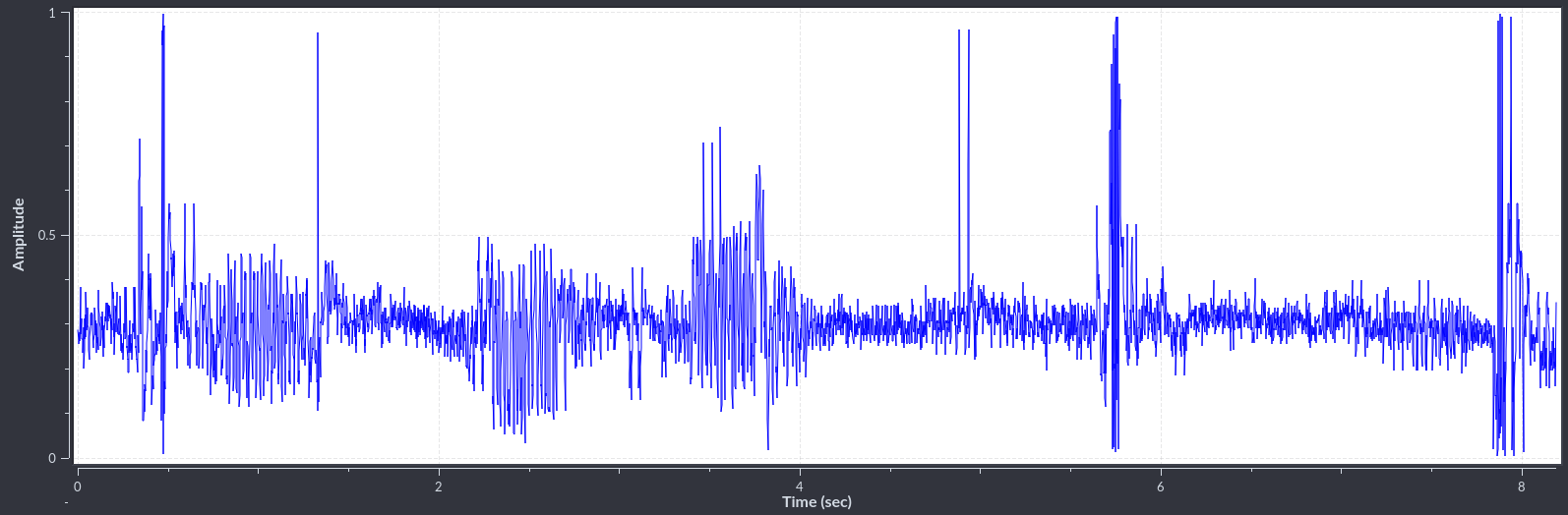

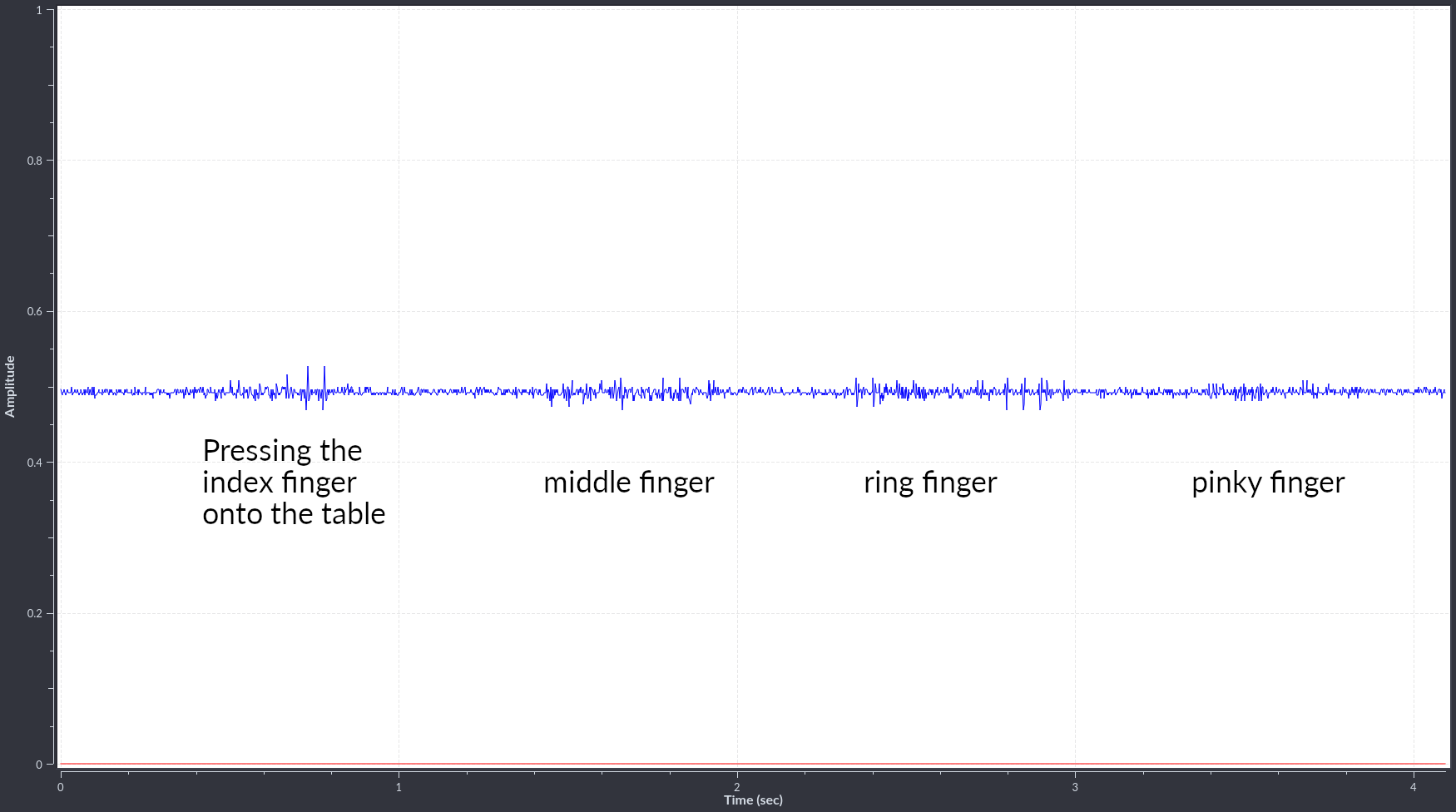

The Signal

A sample of the signal is this, using an INA128 with a gain of x228 and electrodes near the flexor digitorum superficialis:

The baseline is the midly noisy line around a value of 0.3 and shows the state

of rest.

The spikes and "spindles" (periods of higher amplitude) occured when I

performed various movements, like extending the arm, snapping the fingers, or

twisting the wrist.

Bugs in the BP4

The Power Module 4 is not perfect though:

- The solder jumper J8, that activates the central Screw 5, overlaps with the

battery clip, resulting in a short circuit with the battery's ground, unless

I put some isolation tape over the jumper... Need to move the jumper further

away.

- The power switch (SW1) is too close to the Screw 2, so the switch I wanted to

use didn't actually fit, and I had to fall back to one that points off to the

side, and looks a little awkward.

- I also wish that the analog pins were closer to the power pins, so that I can

bundle up the wires, resulting in what would appear like one single

connector, rather than two, per Electrode Module 3. Although this may

lead to EM interference between the wires, reducing the quality of the

signal, so maybe it's actually better this way.

Prototype 8 Demo Video

└2021-12-19, by Roman

The demo video of Prototype 8 is out now:

HackChat & Hackaday Article

└2022-01-18, by Roman

Someone at Hackaday kindly invited me ("hut") to host a Hack Chat about

Electromyography and

PsyLink on

Wednesday, January 19, 8 PM GMT. There, I will answer all sorts of questions

from the hackaday community.

Drop by too, and watch me struggle for an hour to pretend that I know what I'm

talking about :)

Someone else at Hackaday also kindly wrote a whole article about

PsyLink,

which sparked nice discussions in the comments, got the P8 Demo

Video over 5k

views, and inspired several tinkerers to reach out to me about getting their

own PsyLink :)

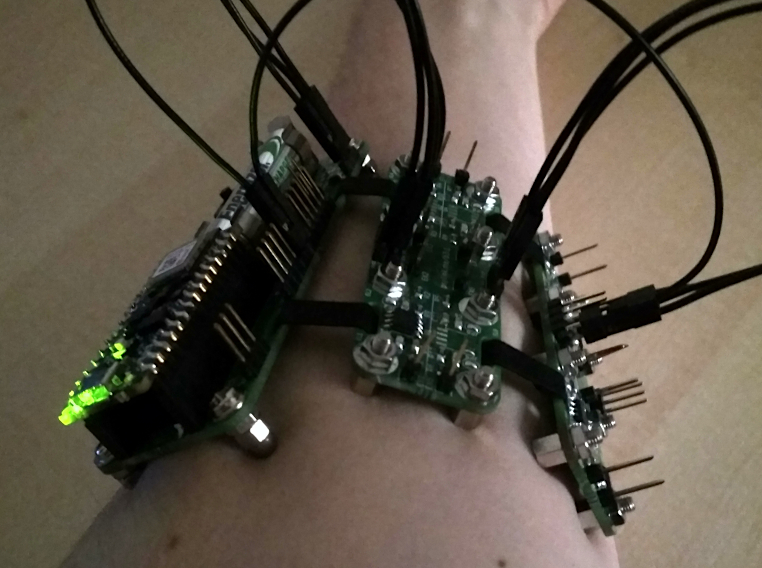

Prototype 9 + Matrix Chatroom

└2022-01-19, by Roman

News #1: PsyLink now has a Matrix chatroom: #psylink:matrix.org

News #2: PsyLink Prototype 9 is now out, which is pretty much the same as Prototype 8,

just with a few bugfixes and enhancements. Notably:

- The Power switch now actually fits on the power module

- The Battery clip doesn't intersect with a solder jumper anymore, which used to cause a short-circuit unless you'd cover it up with tape

- The built-in electrodes on the electrode modules now can be activated/deactivated via solder jumpers, which allows you to use external electrodes while wearing the PsyLink regularily, without the built-in electrodes interfering with the signal.

Obligatory Picture:

It's less colorful and has more boards than the photo of the P8, but that's

just the type of wires, and an additional electrode module. You could make the

P8 look the same way.

Mass production

└2022-02-15, by Roman

More and more people are asking me to send them a PsyLink prototype! I've written some Tutorials to help the users to get started, and I'm working diligently to assemble them all. Can't wait to see the ways in which they will be used. :)

Request your own pre-assembled PsyLink now too!

Unlike software, unfortunately, you can't just download a PsyLink and use it

right away. It takes me about 1-1.5 hours per module to assemble these. I

wish I could automate and outsource more of the assembly process, but I don't

see a low hanging fruit worth exploring so far. Still, I'm happy about the

progress, since I'm now ~5x faster than when I sent out the first Prototype 7.

Currently, the assembly process consists of:

- File off the rough break-off points on the PCB to avoid scratching the skin

- Solder on the SMD components

- Do optical quality tests, as well as tests with a multimeter on critical parts

- Since my pin sockets have 16 pins and the Arduino has 15 pins, I cut off one of the pins of the socket

- Cut the downward-facing pins of all through-hole components down to ~1.4mm so that they don't stick out of the PCB and possibly scratch the skin

- Solder on the Through-hole components (except battery clips)

- Plug in the battery clips, bend its pins inward so that they don't scratch the skin, (the end may break off but that's ok), and solder them on

- Clean off solder flux stains with Isopropyl Alcohol on the sides that face the skin

- Cover the bottom of the power module with insulating tape to avoid skin contact

- Screw on the electrodes / legs

- Wire up everything as described in the wiki

- Push the elastic band through the respective holes to connect the boards together

- Do a test run of the entire system

Outsourcing pick&place and soldering of the components would be helpful, but

the through-hole components (pin headers/sockets, switch, battery clip) need

special treatment: I have to trim the pins so that they don't stick out of the

PCB and scratch the skin. I doubt that any pick&place contractor will do this

for me. This close-up shot of a Electrode Module 3.2 shows it well, that there

are no sharp points under the pin headers, just round solder blobs:

But I could at least outsource the soldering of SMD components. Let's see if I

can find something cheap.

If you have tips to accelerate the assembly process, please reach out to us.

Next Steps & Resources

└2022-02-16, by Roman

The PsyLink Wiki now contains two new pages:

- Next Steps documents potential directions that he project could take in the future

- Resources points to external pages that are connected to PsyLink, similar projects, related news, papers, and educational material.

If you have suggestions for potential next steps or know about interesting links, please let me know, or add them to the wiki. :)

Microchip 6N11-100

└2022-02-22, by Roman

In my quest for premature optimization, I tried out yet another instrumentation amplifier chip: The Microchip MCP6N11-100. At 1.55€, this chip is about 4 times cheaper than the INA128 instrumentational amplifier (which is currently the cost bottleneck), and would make a 16-electrode-PsyLink about half as expensive. It also works with as little as 1.8V (while INA128 requires 4.5V), eliminating the need for power conversion if a 3.7V lithium battery is used.

Unfortunately the pin configuration is different from the INA128 that the Electrode Module 3.1 normally uses, so I had to jury-rig the board a little:

But it worked, and the signal (the first one) is similar enough to those of INA128s (the last 4):

These were recorded with a Prototype 9.1 with two Electrode Module 3.1, one with 1x MCP6N11-100 at a gain of x501, and one with 4x INA128 with gains of x501 as well. I'm wearing it much like on the P8 demo video, except that there's two electrode modules side by side, not just one.

In the top center of the first picture (light blue signal), you can see that there is some clipping in the negative peaks of the wavelet, which is not great, but other than that, it does seem to show very similar signals. (They shouldn't be identical, of course, because each signal measures electrodes at different locations on the arm)

There's also a similar chip, the MCP6N16, which has a smaller footprint size and better performance, but has slightly higher cost and worse availability. It's more difficult to solder, too. But it's good to know that there's the option to switch to that one if we ever need to.

I'm quite happy with this result, and perhaps the next iteration of the electrode module will be designed for this chip rather than the INA128. :)

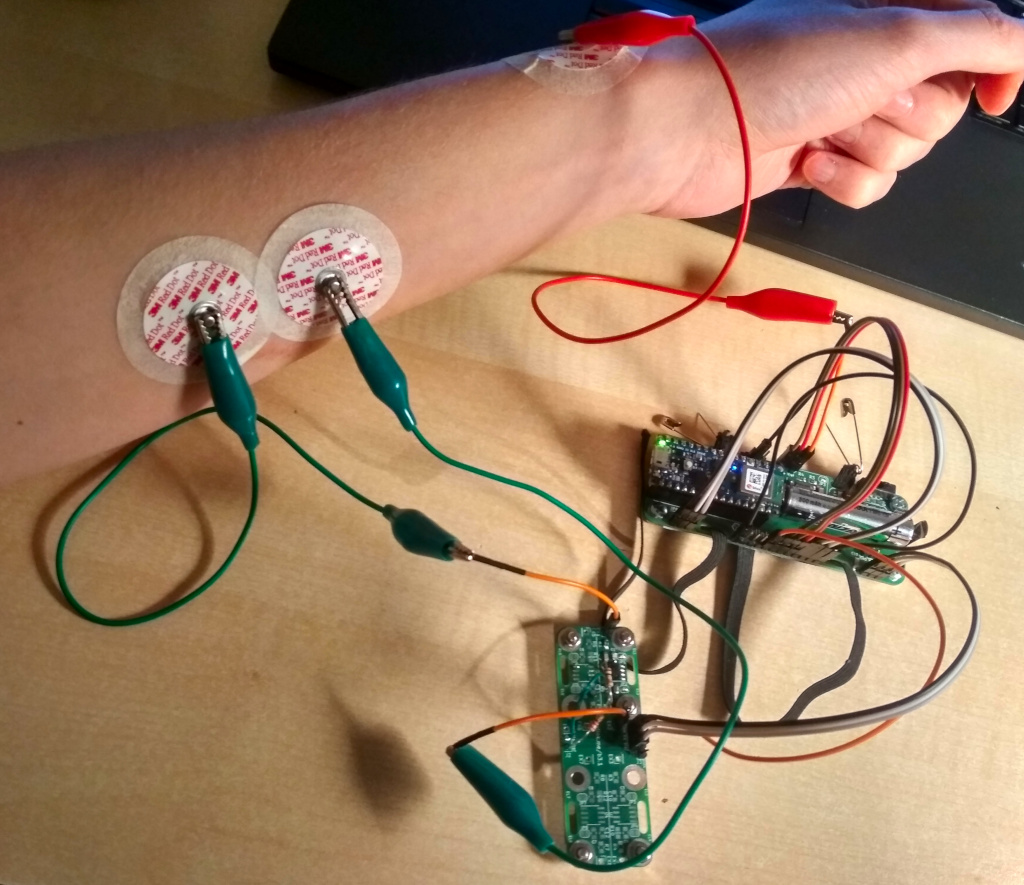

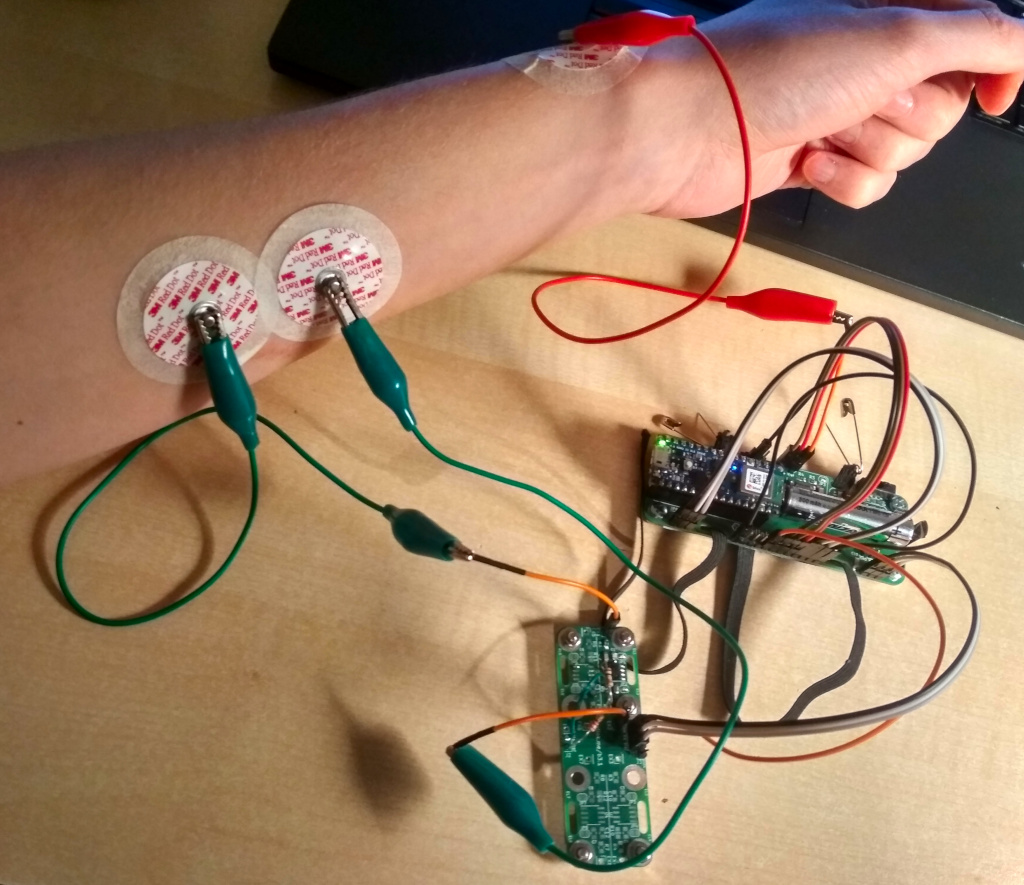

3M Red Dot electrodes

└2022-02-23, by Roman

Alex Lao suggested to try some 3M Red Dot electrodes, and so I got me some of the model 2248-50 (he actually suggested model 2660 but I mixed it up.) They are used for ECG patient monitoring, which is close enough, right?